Hydraulic gas compressor

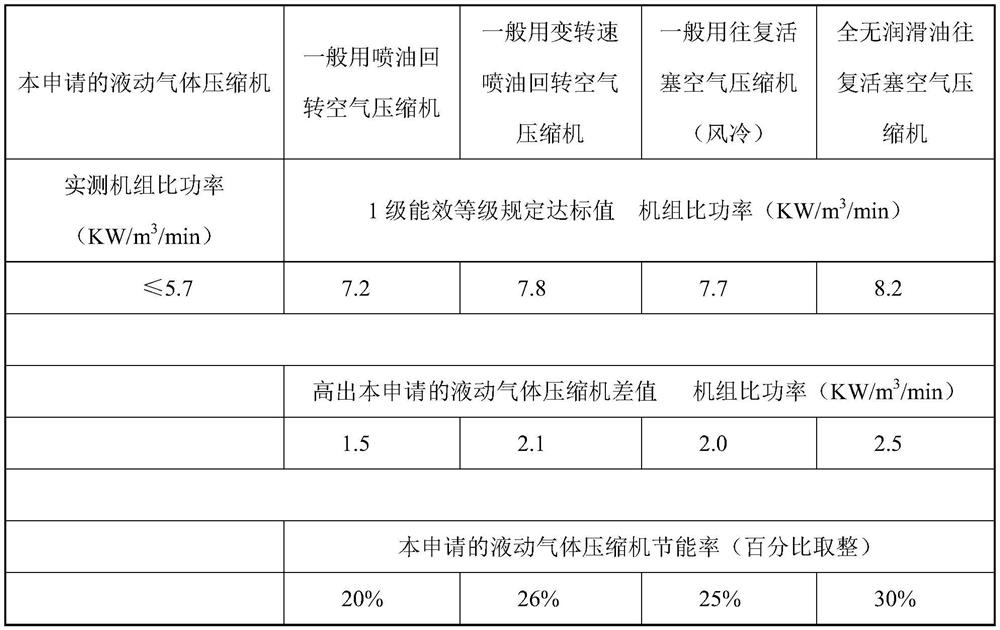

A gas compressor, hydraulic technology, applied in liquid variable capacity machinery, machines/engines, mechanical equipment, etc., can solve the problems of decreased energy efficiency, overloaded operation of supporting motors, damage to pump accessories, etc. Save energy, improve ease of installation and movement, and reduce footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Such as figure 1 As shown, a hydraulic gas compressor mainly includes a tank A 4 , a tank B 15 and a two-way liquid booster pump 2 . The lower parts of tank A 4 and tank B 5 are filled with liquid, and the top of the liquid is filled with air. The bottom of A tank 4 is provided with A tank liquid inlet and outlet pipe 1, and the top of A tank 4 is provided with A tank outlet valve 7, and A tank 4 is provided with A tank inlet valve 6. The bottom of the B tank 15 is provided with a B tank liquid inlet and outlet pipe 17, and the top of the B tank 15 is provided with a B tank gas outlet valve 12, and the B tank 15 is provided with a B tank inlet valve 13. Both ends of the two-way liquid pressurizing pump 2 are respectively connected with the liquid inlet and outlet pipe 1 of tank A and the liquid inlet and outlet pipe 17 of tank B.

[0028] working principle:

[0029] The process in which tank A liquid 3 is injected into tank B 15 under pressure (referred to as the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com