Linkage adjustment double-edge boring head cutter

A boring head and cutting tool technology, which is applied in the field of linkage adjustment of double-edged boring head cutting tools, can solve problems affecting the quality of workpiece holes, cutting tool head fragmentation, and tool head size difference, so as to save debugging time, reduce difficulty, The effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

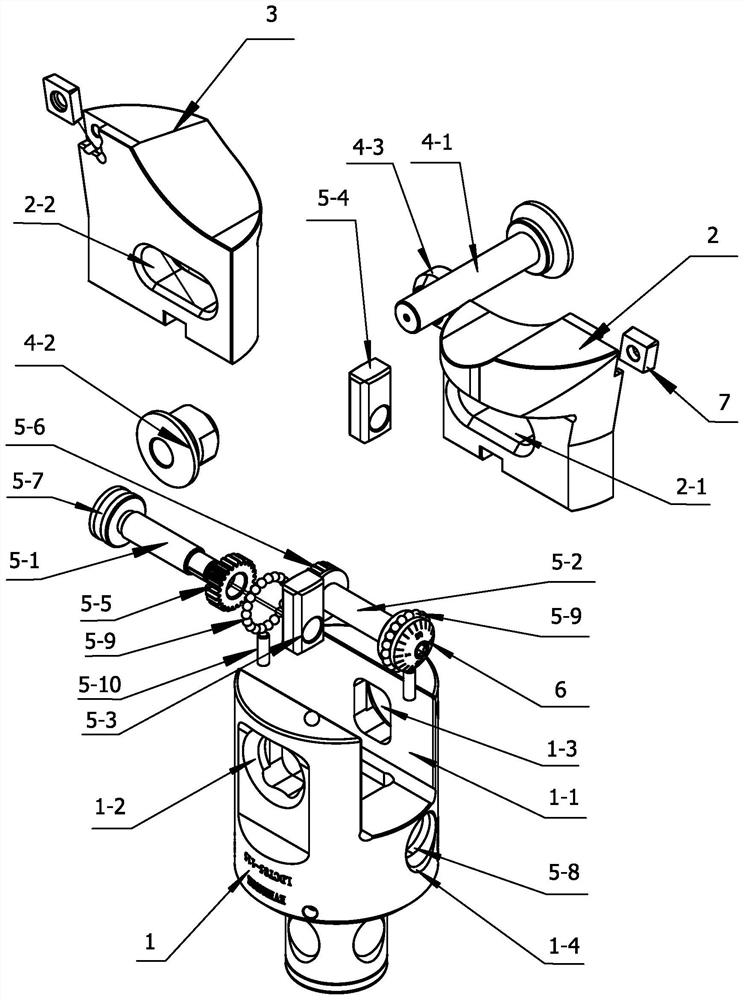

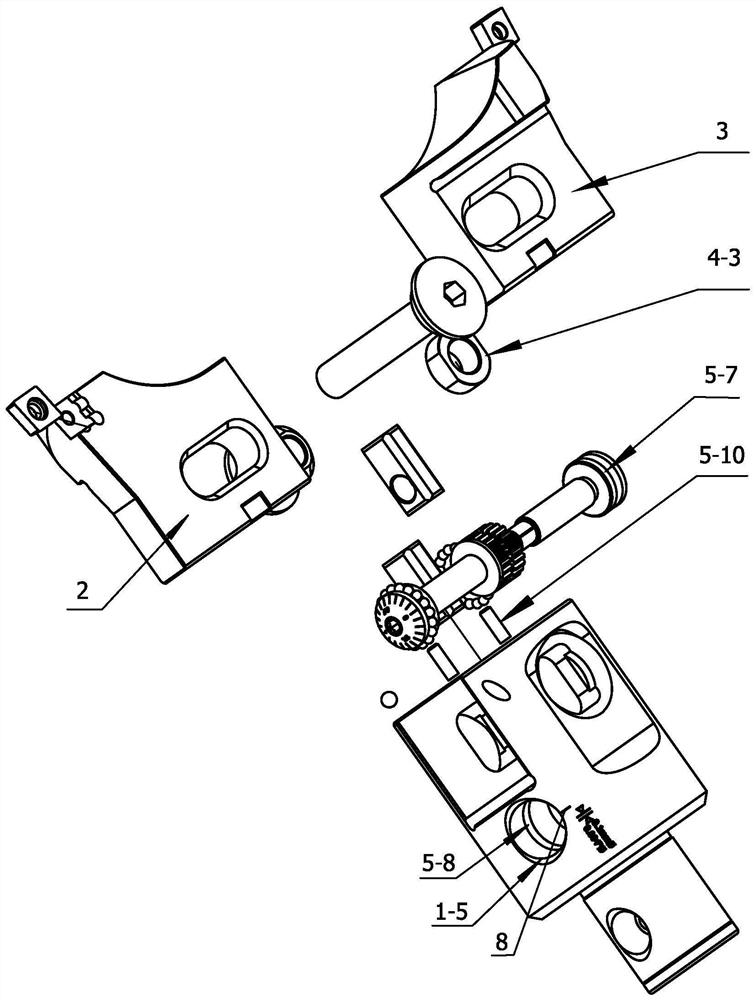

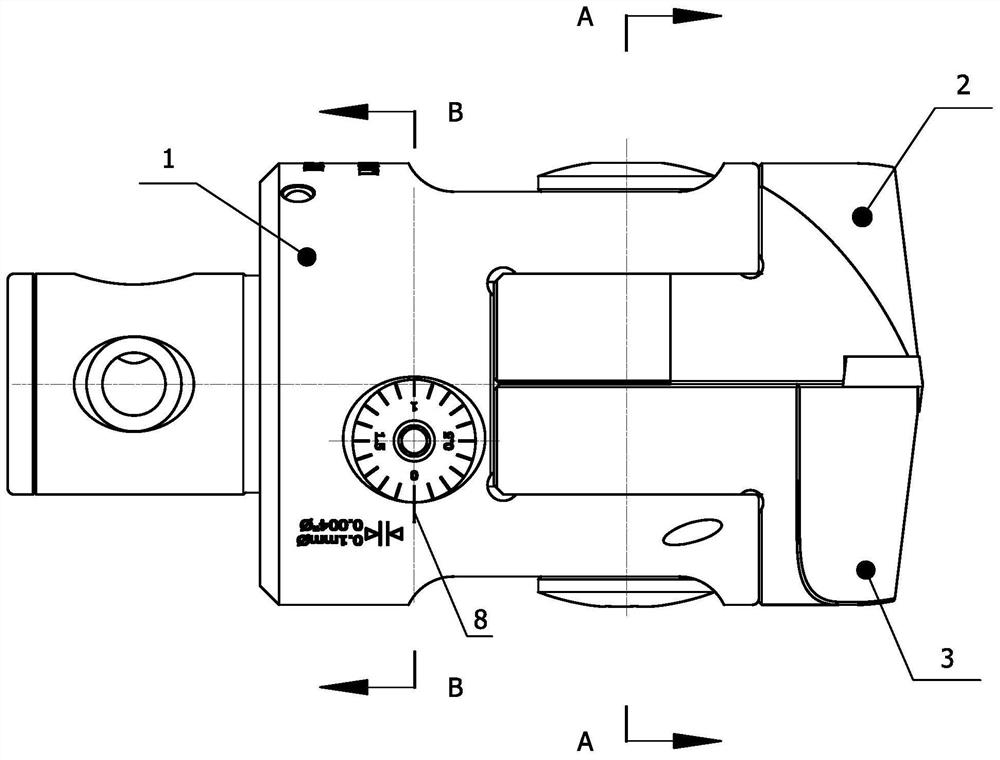

[0032] Such as Figure 1 to Figure 10 The linkage adjustment double-edged boring head tool shown includes a tool seat 1, a first slider assembly 2, a second slider assembly 3, a locking assembly and a driving assembly. A U-shaped through groove 1-1 is opened on the knife seat; the first slider assembly and the second slider assembly can slide in the U-shaped through groove in opposite directions, and the two slider assemblies A cutter head 7 is installed on the outside, so that the workpiece hole is cut. In this embodiment, the notch width of the U-shaped through groove is adapted to the thickness of the two slider assemblies (that is, after the two slider assemblies are loaded into the U-shaped through groove, the inner wall of the U-shaped through groove and the two sliders There is a certain gap between the block assemblies) to ensure that the two slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com