Exhaust gas aftertreatment device

A technology of exhaust post-treatment and equipment, which is applied in the direction of exhaust treatment, mechanical equipment, exhaust devices, etc. It can solve the problems of inability to ensure exhaust post-treatment and the limitation of predetermined structural space, etc., to achieve improved particle separation, Effect of High Discharge Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

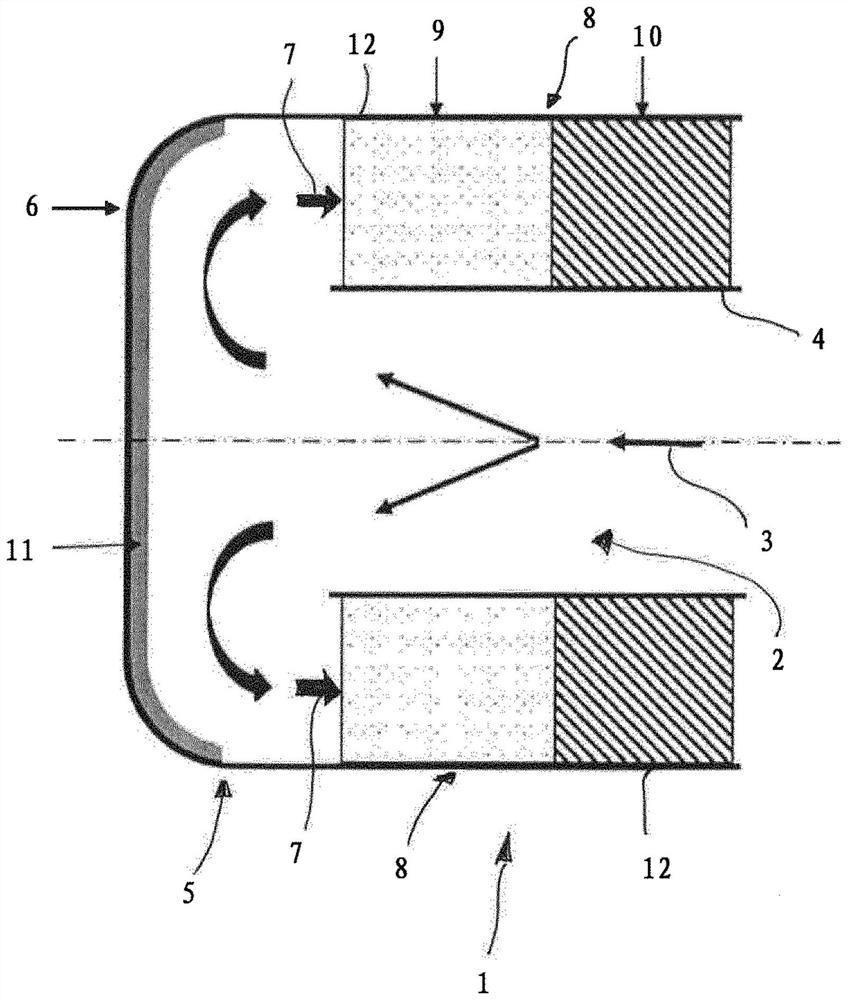

[0027] figure 1 An annular catalytic converter 1 is shown. The annular catalytic converter has a centrally located first tubular flow section 2 through which exhaust gas can flow in flow direction 3 . The tubular flow section 2 is bounded in the radial direction by an inner tube 4 . A deflection region 5 is arranged downstream of the tubular flow section 2 in the flow direction 3 .

[0028] The diversion area 5 is formed by a cover element 6 onto which the exhaust gas flowing through the tubular flow section 2 flows. By impinging on the cover element 6 , the exhaust gas is deflected radially outwards and finally in a flow direction 7 , which is 180° opposite to the flow direction 3 .

[0029] The exhaust gas then flows through the second annular flow section 8 through a plurality of elements for exhaust gas aftertreatment arranged in this flow section 8 . exist figure 1 shows an annular catalytic converter 9 which, for example, has a catalytically active coating in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com