Battery cover quality detection method and device, computer equipment and storage medium

A quality inspection method and battery cover technology, which are applied in computing, image data processing, instruments, etc., can solve the problems of difficulty in full inspection of the battery cover and large error of the battery cover, and achieve the effect of saving manpower and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

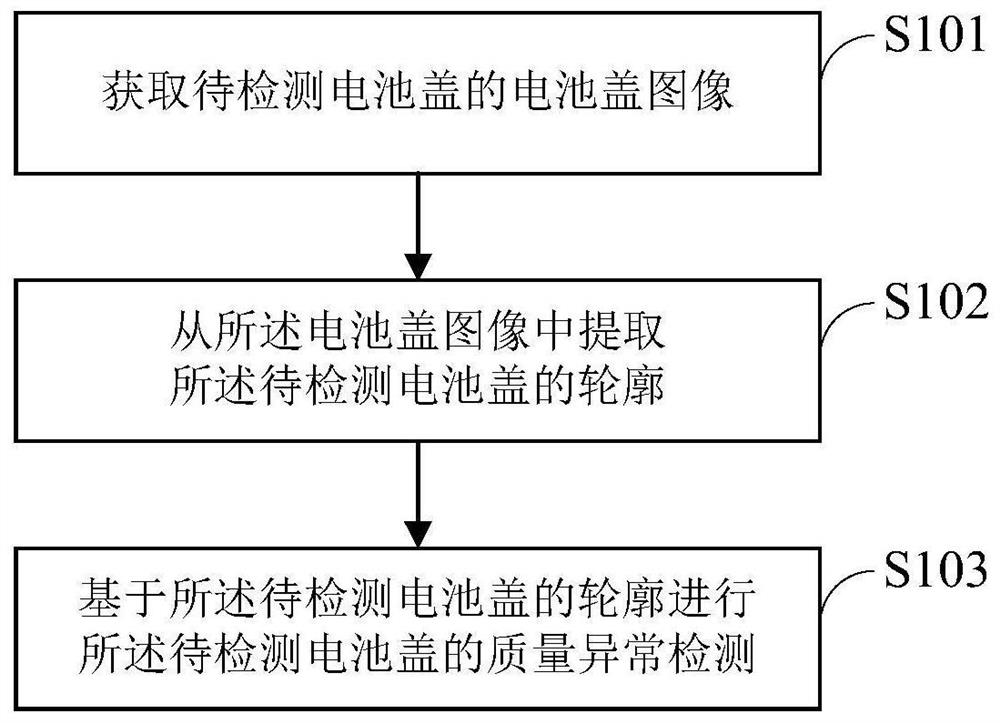

[0069] Such as figure 1 As shown, it is a flow chart of the battery cover quality detection method provided by the embodiment of the present invention. The battery cover quality detection method may include the following steps:

[0070] Step S101: Obtain the battery cover image of the battery cover to be detected.

[0071] In practical applications, the camera can be fixedly installed at a set height, and a scale with a known length can be set. It should be noted that, in order to locate the scale from the captured image, the scale is usually set to be the same as the object to be collected. Different and unique, and placed at a fixed position within the camera's field of view, the battery cover image of the battery cover to be inspected that is transported by the conveyor belt can be obtained after installation is ready. For scenarios where the installation position of the camera is fixed, the camera can also be installed according to the set height, and the ratio of the act...

Embodiment 2

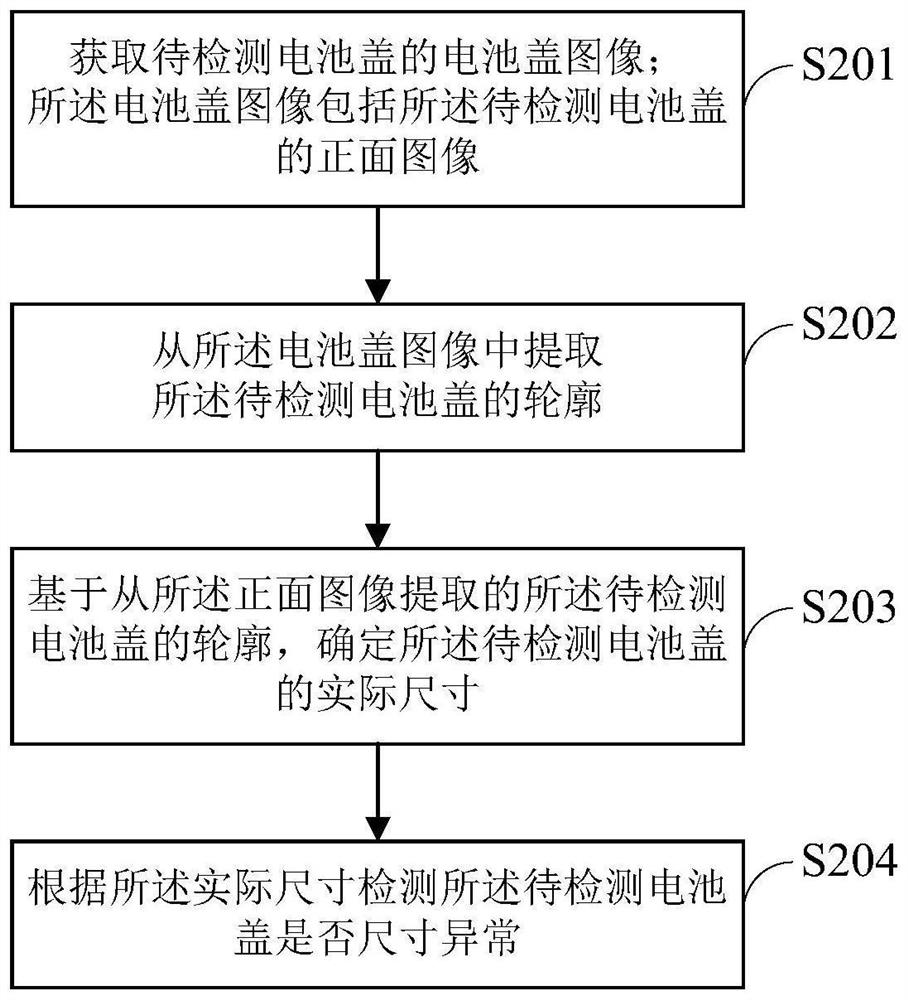

[0079] Such as figure 2 As shown, it is another flow chart of the battery cover quality detection method provided by the embodiment of the present invention. The battery cover quality detection method may include the following steps:

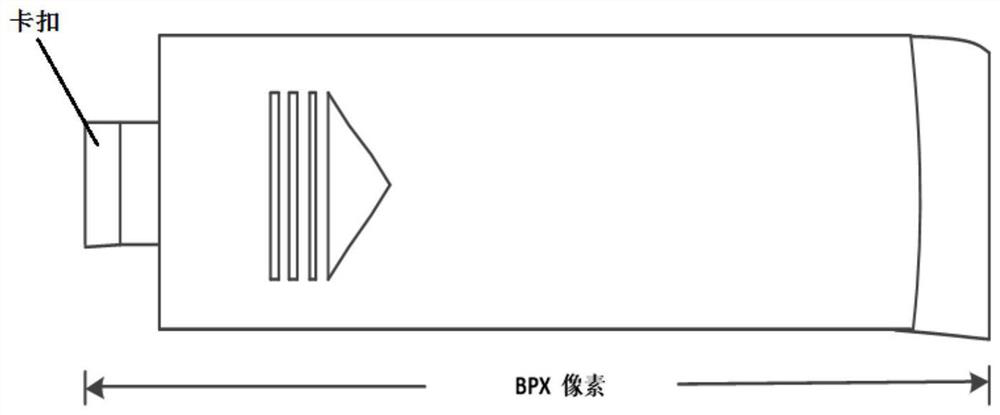

[0080] Step S201: Obtain the battery cover image of the battery cover to be tested; the battery cover image includes the front image of the battery cover to be tested, see image 3 , is a schematic front view of the battery cover to be tested provided by the embodiment of the present invention.

[0081] Step S202: extracting the outline of the battery cover to be detected from the battery cover image.

[0082] Step S203: Determine the actual size of the battery cover to be detected based on the outline of the battery cover to be detected extracted from the front image.

[0083] In an implementation manner, the actual size of the battery cover to be detected can be determined in the following manner: obtain the number of pixels corresponding t...

Embodiment 3

[0088] Such as Figure 4 As shown, it is another flow chart of the battery cover quality detection method provided by the embodiment of the present invention. The battery cover quality detection method may include the following steps:

[0089] Step S301: Obtain the battery cover image of the battery cover to be tested; the battery cover image includes the side image of the battery cover to be tested, see Figure 5 , is a schematic side view of the battery cover to be tested provided by the embodiment of the present invention.

[0090] Step S302: extracting the outline of the battery cover to be detected from the battery cover image.

[0091] Step S303: extracting the deformation detection area from the side image.

[0092] Step S304: Perform edge curve fitting based on the edge of the deformation detection area to obtain a fitting curve of the deformation detection area.

[0093] In an implementation manner, the least square method may be used for edge curve fitting. Of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com