Detachable modular engine oil cooling filter and working method thereof

An oil cooling and filter technology, applied in the field of filters, can solve the problems of difficulty in disassembly, low efficiency of installation and disassembly, etc., and achieve the effects of increasing the scope of application, increasing the anti-seismic function, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

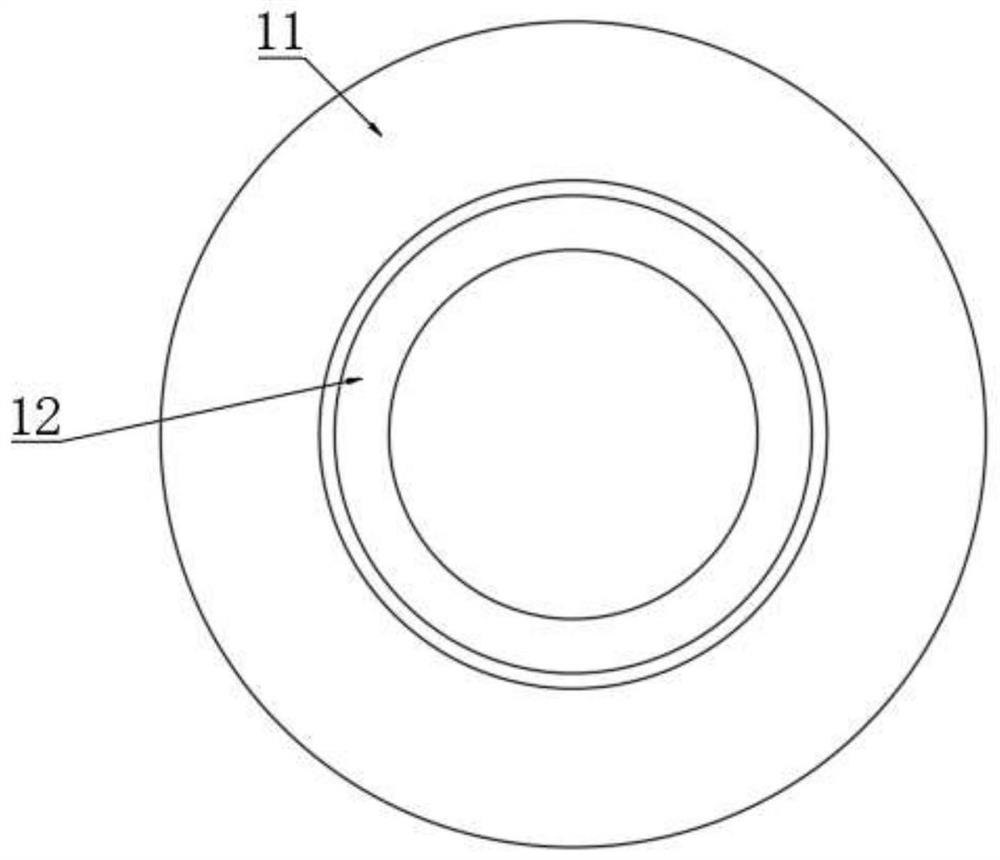

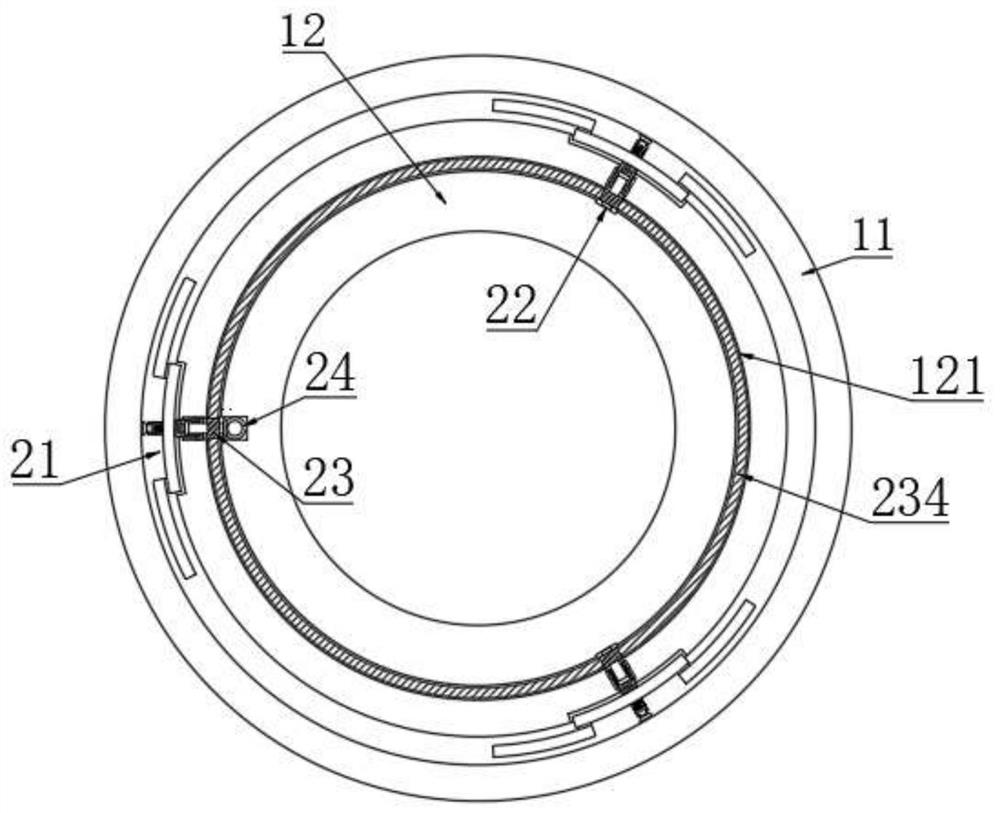

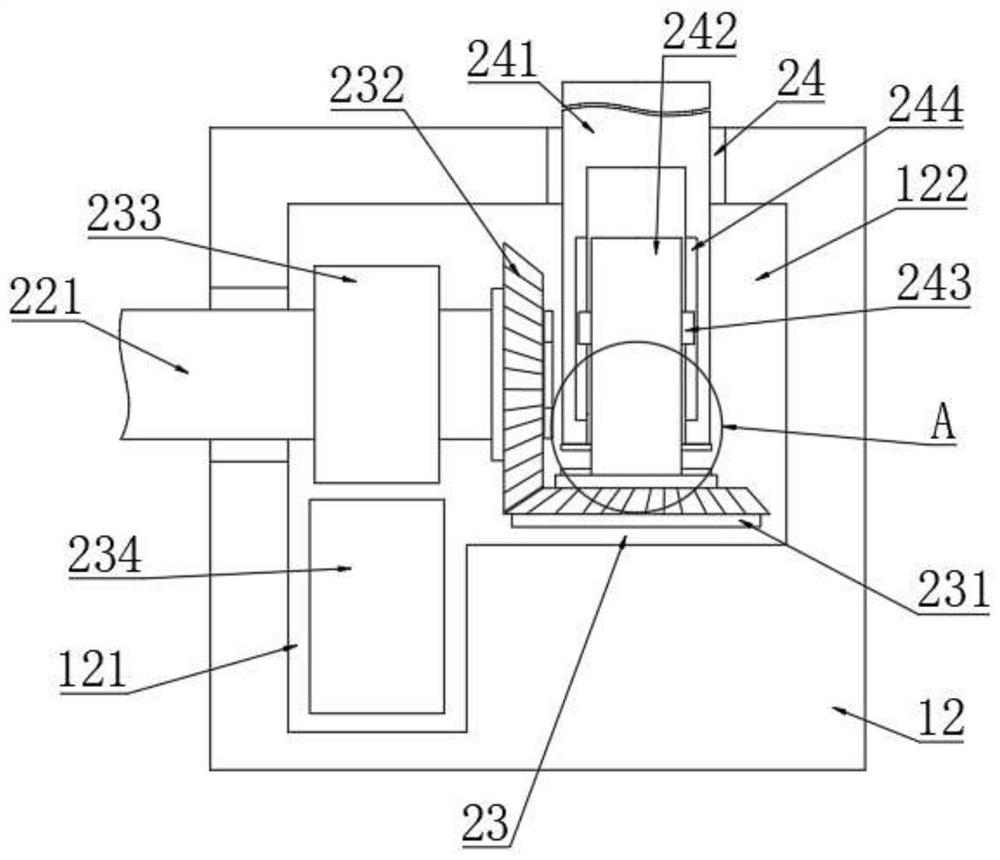

[0037] Such as figure 1 , figure 2 as well as Figure 5 As shown, the detachable modular oil cooling filter in this embodiment includes a central pipe 12 and a fiber filter paper tube 11 sleeved outside the central tube 12. A connection assembly 21, the connection assembly 21 includes an arc-shaped plate part 212 that can be extended to both ends, and the surface of the arc-shaped plate part 212 is provided with an adsorption part 211 with an elastic adsorption function on the axial midline; The interior accommodates a push assembly 22 that can extend radially. The end of the push assembly 22 away from the connecting assembly 21 is connected to a rotating assembly 23 with a transmission function. The rotating assembly 23 is connected to a force applying assembly 24. The connecting assembly 21 is pushed by the pushing assembly 22 to radially extend along the end of the central tube 12 , and the adsorption member 211 elastically adsorbs to the inner surface of the fiber filte...

Embodiment 2

[0050] refer to Figure 1 to Figure 8 , the working method of the detachable modular oil cooling filter of the present embodiment includes the following steps,

[0051] S1. According to the size of the fiber filter paper tube 11 and the central tube 12, extend the two ends of the arc-shaped plate member 212, so that the inner diameter of the arc-shaped plate member 212 and the fiber filter paper tube 11 roughly match, and set the fiber filter paper tube 11 On the outside of the central tube 12, both ends are aligned;

[0052] S2. Stretch the extension rotating rod 241 upwards to separate the first magnetic coil 2421 from the second magnetic coil 2422 until the height of the extension rotating rod 241 is appropriate;

[0053] S3, drive the first bevel gear 231 to rotate by rotating the extension shaft 241, and then drive the second bevel gear 232 and the driven gear 233 to rotate, and the driven gear 233 corresponding to the second bevel gear 232 drives the gear ring 234 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com