Equipment and method for inhibiting early oxidation of residual coal in goaf

A goaf and equipment technology, applied in mining equipment, mining equipment, safety devices, etc., can solve problems such as increased difficulty in governance, fire, waste of resources and the environment, and achieve comprehensive prevention and control, wide coverage, and increased The effect of air leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

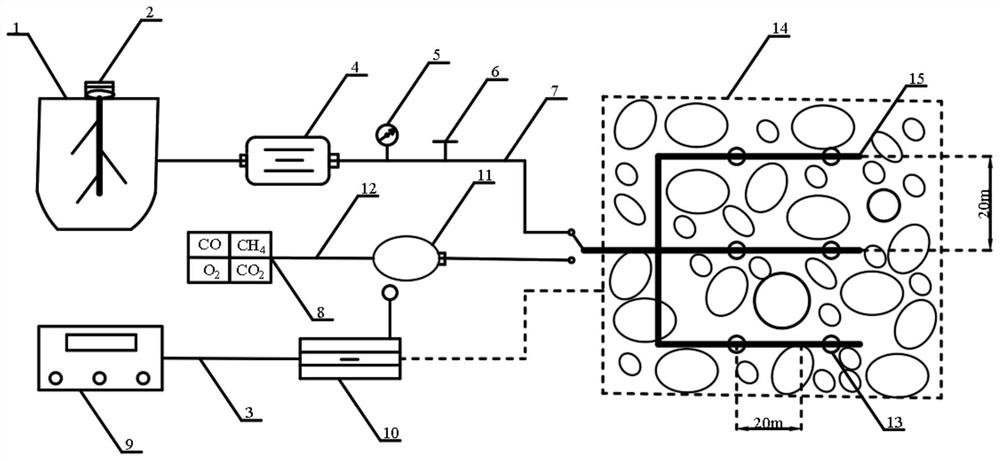

[0028] Such as Figure 1 to Figure 3 As shown, a kind of equipment for suppressing early oxidation of residual coal in goaf, including grouting system, automatic grouting system, temperature monitoring system and gas detection system;

[0029] The grouting system includes a pulping barrel 1, a wind mixer 2, a screw pump 4 and a slurry delivery pipeline 7, the wind mixer 2 is installed in the slurry barrel 1, and the slurry barrel 1 passes through the connection between the pipeline and the screw pump 4. The inlet is connected, the outlet of the screw pump 4 is connected to one end of the slurry delivery pipeline 7, and the slurry delivery pipeline 7 is equipped with a pressure gauge 5 and a slurry delivery valve 6;

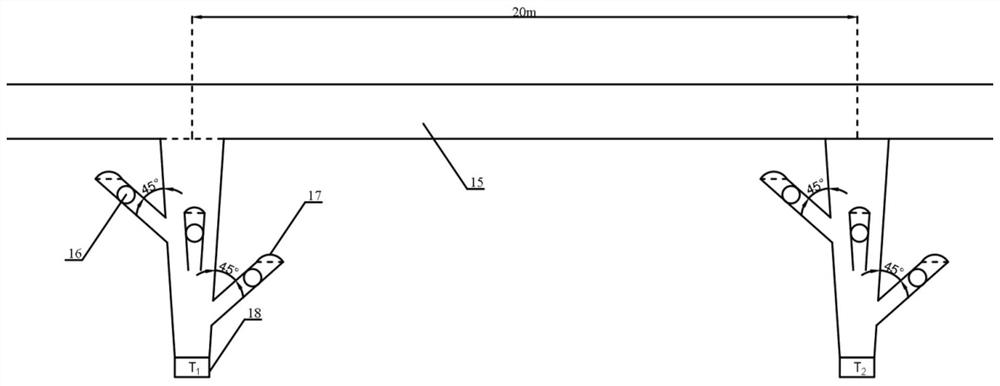

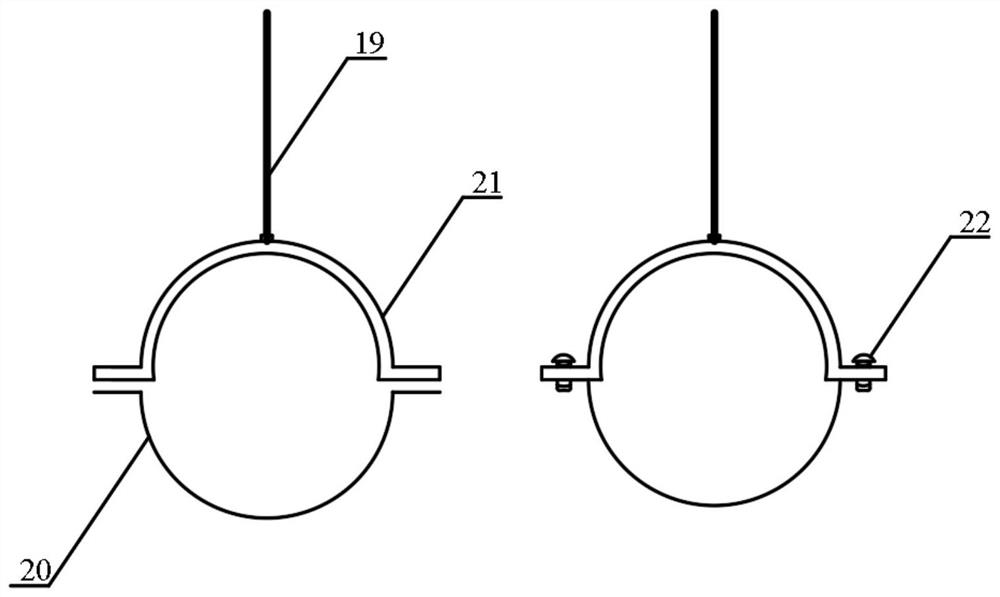

[0030] The automatic grouting system includes a main pipeline and a plurality of branch pipelines 15, one end of the multiple branch pipelines 15 is blocked, and the other end is connected to one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com