Cable-stayed bridge cable guide pipe positioning method

A positioning method and technology for cable-stayed bridge cables, applied in cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of cable guide deviation, high installation accuracy requirements, and impact on construction period, so as to improve installation accuracy and improve installation efficiency. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

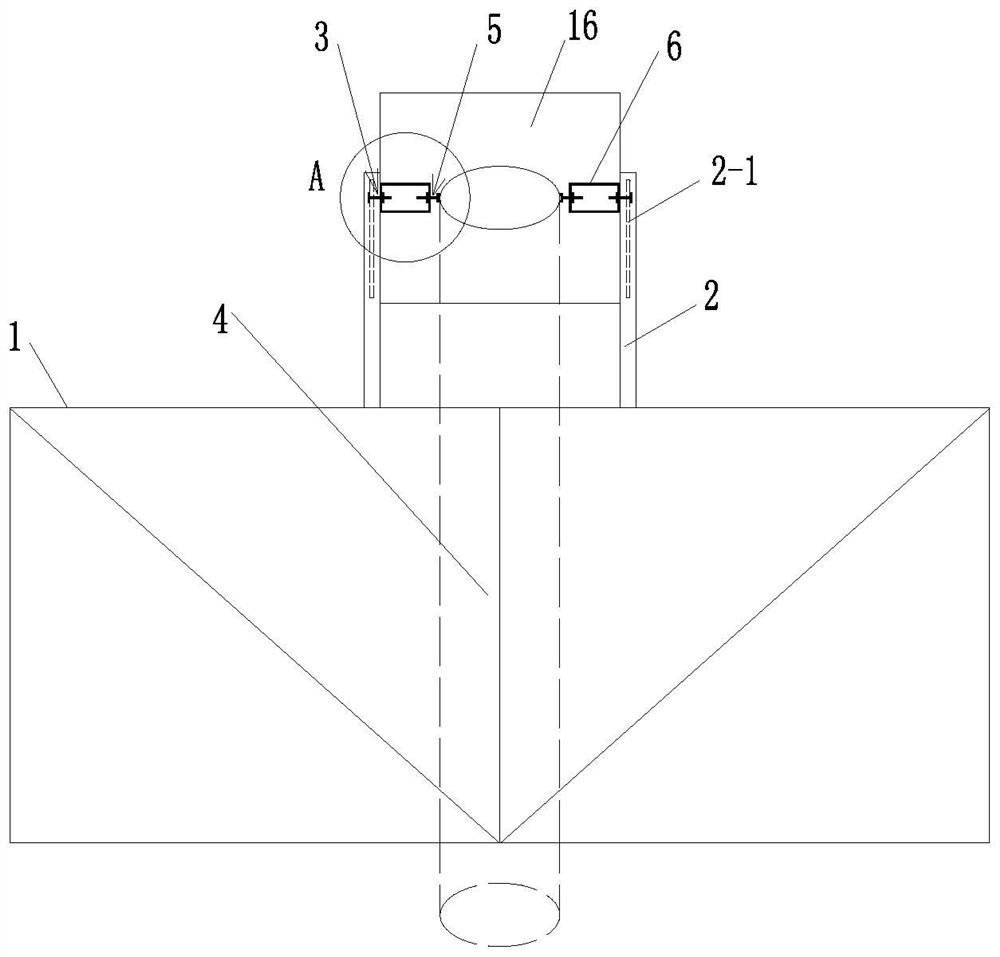

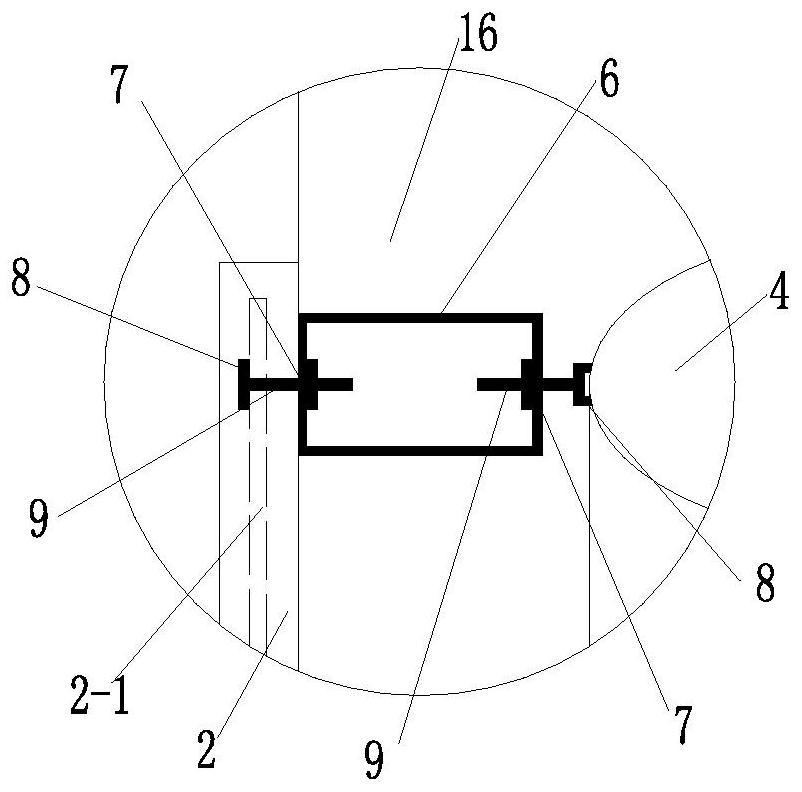

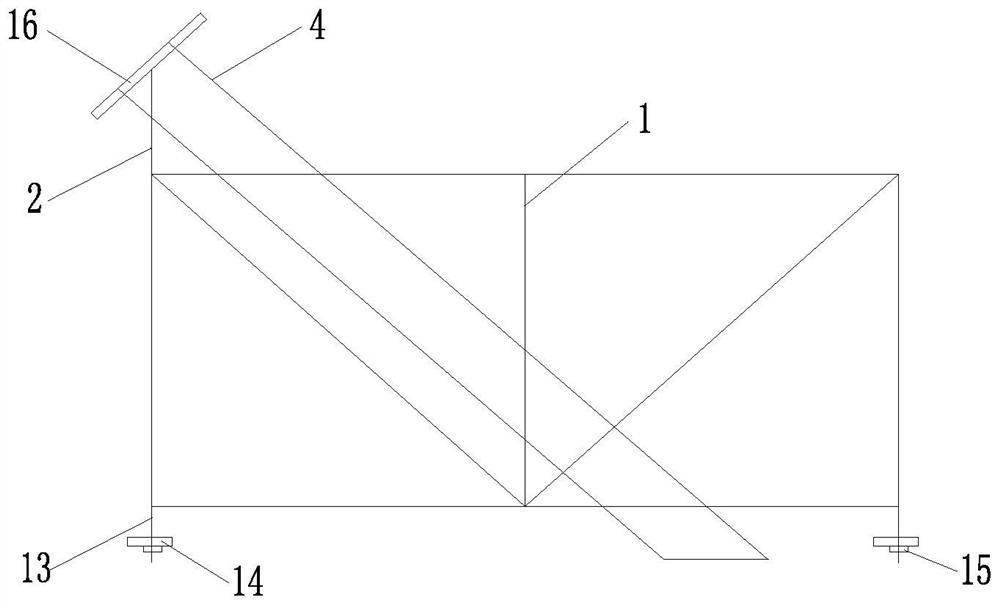

[0052] Such as Figure 1 to Figure 8 A cable guide positioning method for a cable-stayed bridge shown, the method may include the following steps:

[0053] Step 1. Installing the first adjusting part: set up sliding grooves 2-1 on the two supporting rods 2 of the rigid frame 1, and the sliding grooves 2-1 are arranged along the height direction of the supporting rods 2, so that The sliding groove 2-1 is arranged on the upper part of the support rod 2; the first adjusting member 3 is horizontally pierced in the sliding groove 2-1, and the first adjusting member 3 can move along the sliding groove 2-1 move up and down; the end of the first adjusting member 3 passes through the support rods 2 and extends between the two support rods 2;

[0054] Step 2, install the second adjusting part: weld two second adjusting parts 5 horizontally on the outer surface of the cable guide 4, and the two second adjusting parts 5 are arranged symmetrically on the top of the cable guide 4;

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com