Synthesis method of high-content bispyrithione

A bipyridinethione and synthesis method technology, applied in the field of bispyridinethione preparation, can solve the problems of low yield and content, inability to meet the needs of daily chemical products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

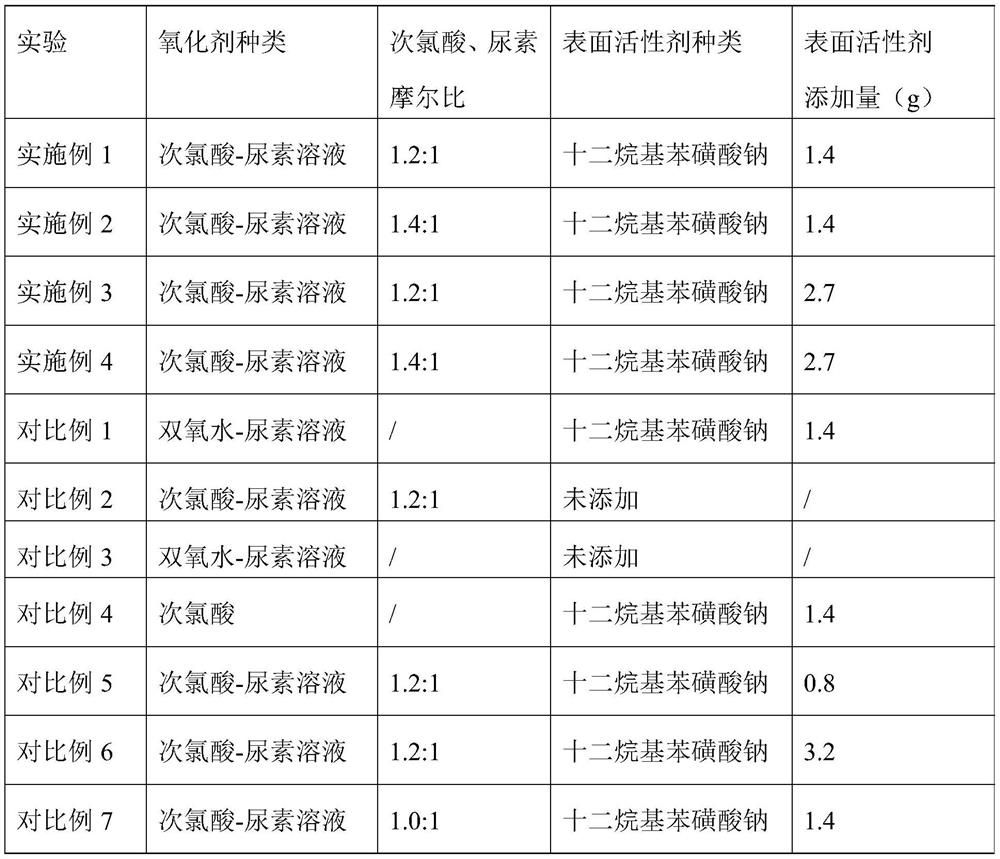

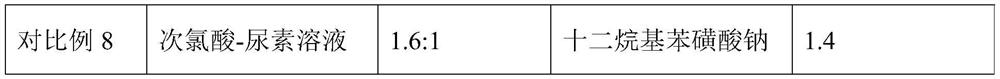

Examples

preparation example Construction

[0022] Scheme overview: a kind of synthetic method of high-content dipyridinethione, comprises the following steps:

[0023] Step I: Nitrogen oxidation reaction, add solvent, catalyst and 2-chloropyridine to the reactor and stir evenly, the molar ratio of 2-chloropyridine and catalyst is 1:1~2, the mass ratio of 2-chloropyridine to solvent is 1: 0.5-1; the solvent in this embodiment is distilled water, and the catalyst is a titanium-silicon molecular sieve catalyst (IEZ-Ti-MWW catalyst); then hydrogen peroxide is added dropwise at 40-100°C, and after the dropwise addition is completed, the insulation reaction is carried out for 2-5h. After the reaction was completed, the filtrate was obtained by suction filtration under reduced temperature, and the 2-chloropyridine nitrogen oxide solution was obtained.

[0024] Step II: mercaptolation reaction, add sodium hydrosulfide solution and sodium hydroxide solution to the reaction kettle, the concentration of sodium hydrosulfide is 35-...

Embodiment 1

[0030] A kind of synthetic method of high-content dipyridinethione, comprises the steps:

[0031] Step I: Nitrogen oxidation reaction, add 100g of 2-chloropyridine, 75g of distilled water and 2g of IEZ-Ti-MWW catalyst respectively in a 500L four-necked flask, start stirring and raise the temperature to 40°C, then add 97g of hydrogen peroxide with a mass fraction of 35% dropwise, and control the temperature Between 60-80°C. After the dropwise addition, keep warm for 4 hours, cool down to 40°C after the warm keeping, filter to get 2-chloropyridine nitrogen oxide, and the filter cake is used for recovery of the catalyst for later use;

[0032] Step II: mercaptolation reaction, add 117g of 45% sodium hydrosulfide solution and 107g of 32% sodium hydroxide solution in a 1000L four-neck flask, start stirring and heat up to 60°C, start adding the above obtained filtrate 2-chloropyridine nitrogen oxidation Control the reaction temperature at 60-70°C, keep the reaction for 3 hours afte...

Embodiment 2

[0037]The difference between this embodiment and Example 1 is that the molar ratio of hypochlorous acid to urea is 1.4:1.0: in this embodiment, step III: the oxidizing agent is hypochlorous acid-urea solution, and its preparation process is as follows: weigh 350g 13% sodium hypochlorite solution, pass through carbon dioxide gas to saturation, set aside. Add 26.5 g of 99% urea to the above solution and stir evenly to obtain hypochlorous acid-urea solution.

[0038] In the bipyridinethione synthesis step, weigh 100g of 2-mercaptopyridine-N-oxide and 300g of pure water in a 1000ml four-neck flask to disperse them, add 1.4g of sodium dodecylbenzenesulfonate, stir to dissolve, and heat up To 45°C, add hypochlorous acid-urea solution dropwise, after the dropwise addition, raise the temperature to 55-60°C for 1 hour, filter with suction, wash, refine with ethanol, and dry under reduced pressure at 55°C to obtain off-white solid bispyridinethione 90.3g, content 98.9%, yield 91.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com