Multifunctional combined sludge discharge device

A sludge discharge device and combined technology, applied in sludge treatment, fixed filter element filter, water/sludge/sewage treatment, etc., can solve the problems of shortened process flow, high investment cost, difficult operation, etc. The effect of simple operation, simple equipment structure and less electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

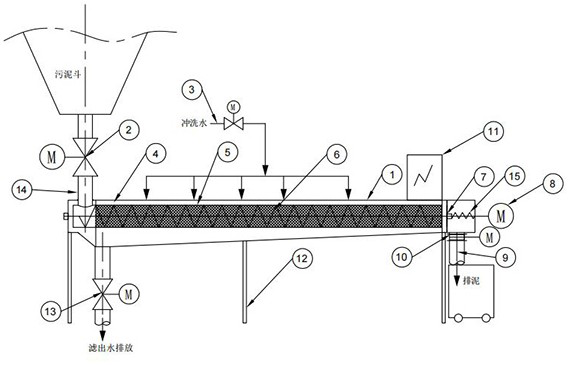

[0030] A multi-functional combination slurry device, such as figure 1 As shown, including the apparatus body 1, the apparatus body portion is an outer inner circular type, and the internal pipe structure; the lower portion of the apparatus main body is placed on the leg 12, and the support load load of the leg 12 is supported; the apparatus body 1 end Connecting in the mud gate 14, the lower portion of the other end is connected to the slot 9.

[0031] like figure 1 As shown, the upper end of the inverting 14 is connected to the sludge strip, and the sludge produced by the ground sludge concentrator / sludge precipitation tank is stored in the lower part of the pool body, typically set timing according to the sludge residence time design of the pool. During the mud, according to the sludge characteristics according to the sludge characteristics, the excreted amount of mud has reached 3% to 5%;

[0032] There is a sludge in the lower end of the mud 9, and the sludge (water content ...

Embodiment 2

[0048] This embodiment is substantially the same as the embodiment of the embodiment, and the difference is:

[0049] The opening and closing device also includes a fender 7, and the fender 7 is actively connected to the apparatus body 1, and its motion position includes a closed bit to stand at one end of the cylindrical filter 5 and an open position away from the cylindrical filter 5;

[0050] In this embodiment, the fender 7 is slipped in the main shaft direction, and the device body 1 is provided with a telescopic spring 15 between the end surface and the fender 7, and the retractable spring 15 is set to the main shaft and fixed. The fender 7 welding is fixed, and the retractable spring 15 drives the fender 7 against one end of the cylindrical filter 5;

[0051] The spiral pusher continuously pushes the sludge after dehydration to the left side of the fender 7, and when the pressure is greater than the thrust of the telescopic spring 15, the slime 7 is opened, the sludge after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com