High-salinity sewage treatment equipment

A technology for treating equipment and high-salt sewage, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as high operating costs, large investment, and difficulty in achieving purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

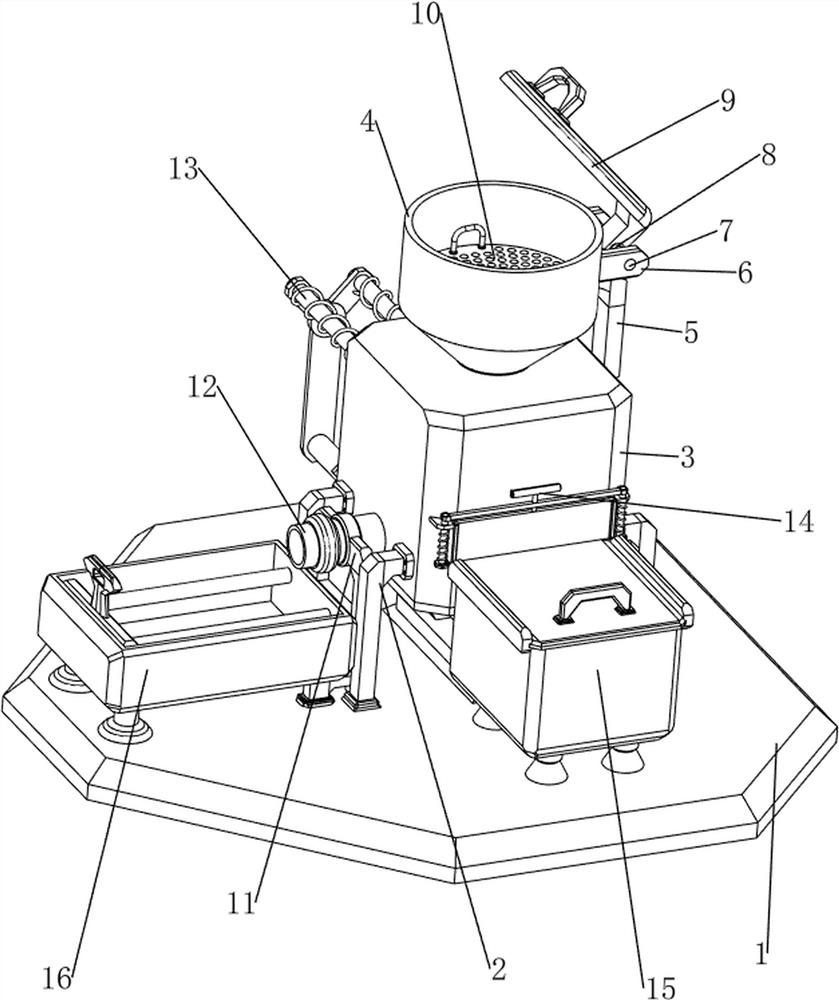

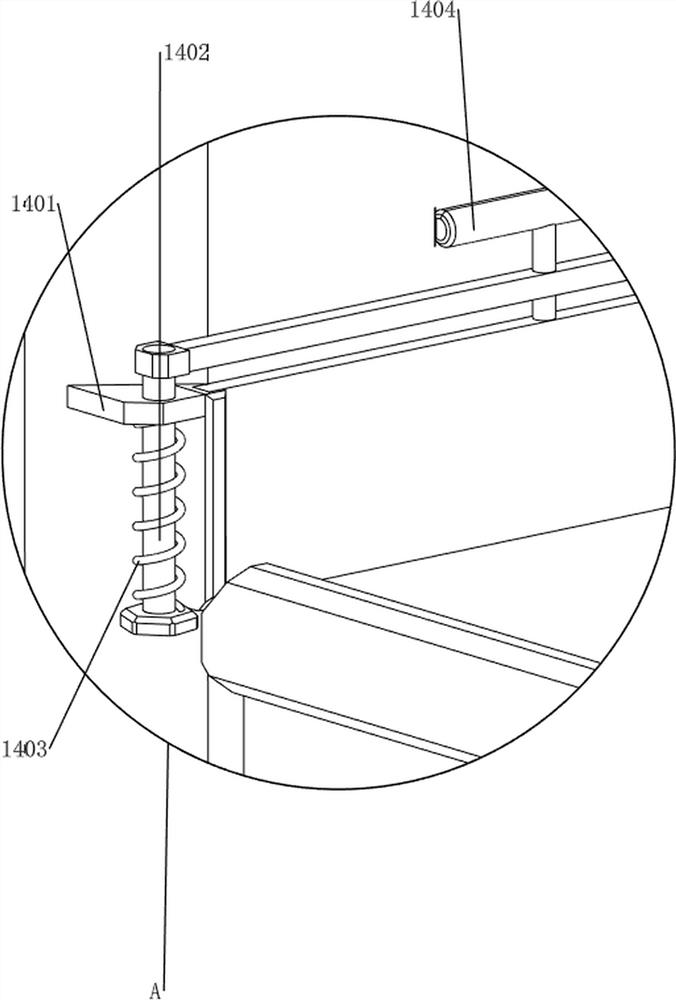

[0024] A high-salt sewage treatment equipment, such as Figure 1-4 As shown, it includes a base 1, a first bracket 2, a first shell 3, a feed hopper 4, a connecting block 5, a first fixing block 6, a first connecting rod 7, a first spring 8, a flip cover 9, and a filter plate 10 , the second support 11, the water pipe 12, the sewage pushing mechanism 13 and the opening and closing mechanism 14, the left and right sides of the middle right part on the base 1 are symmetrically provided with the first support 2, and the first support 2 is arranged between the tops of the four first support 2 A shell 3, the top of the first shell 3 is provided with a feed hopper 4, a connecting block 5 is provided between the right wall of the feed hopper 4 and the right wall of the first shell 3, and the upper part of the right wall of the feed hopper 4 is symmetrically provided with a first fixed Block 6, the first connecting rod 7 is arranged between the right sides of the two first fixed block...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , Figure 5 and Image 6 As shown, a collection mechanism 15 is also included, and the collection mechanism 15 includes a first support block 1501, a second housing 1502, a second fixed rod 1503, a fourth spring 1504, a second push rod 1505 and a slide block 1506, on the base 1 The front and rear of the right side of the front part are symmetrically provided with first support blocks 1501, and the tops of the four first support blocks 1501 are provided with second shells 1502. A second push rod 1505 is slidably arranged between the two second fixed rods 1503, and the front part of the second push rod 1505 is slidably connected with the second housing 1502, and a fourth spring 1504 is wound on the second fixed rod 1503. The two ends of the spring 1504 are respectively connected with the second fixed rod 1503 and the second push rod 1505 on the same side, and the rear end of the second push rod 1505 cooperates with the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com