A kind of preparation method and product of aluminum-lithium alloy based on graphite sand casting mold

An aluminum-lithium alloy and sand casting technology, which is applied in the field of casting, can solve problems such as sand sticking and pores, and achieve the effects of refining grains, preventing sand sticking defects, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

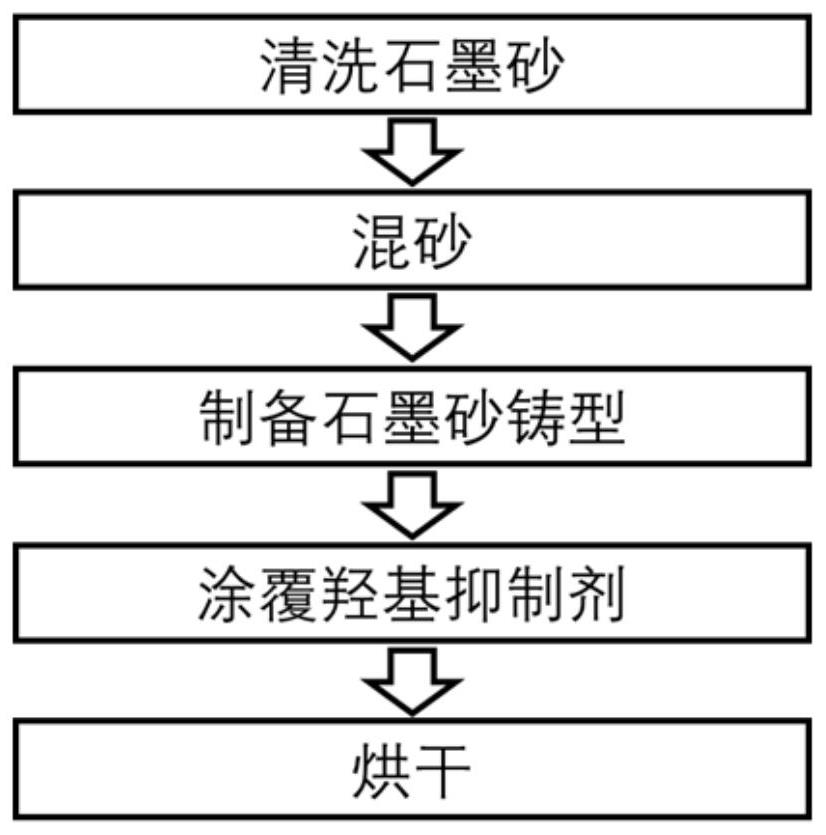

[0028] like figure 1 Shown, a kind of aluminum-lithium alloy preparation method based on graphite sand mold, the method comprises the following steps:

[0029] S1 cleaning graphite sand

[0030] Put the graphite sand into the water, apply mechanical stirring, stop stirring after a period of time, let it stand for a period of time, and pour off the water containing graphite ash in the upper part. Follow the above steps to wash it several times until there is no graphite ash in the water and it becomes clear, then dry it for later use.

[0031] Further, in step S1, the graphite sand is artificial granular graphite sand, the number of mesh is 50-150 mesh, the volume ratio of water and graphite sand in the cleaning process is 1:1, the stirring speed is 300-800rpm, and the stirring time is 0.5~2h.

[0032] Further, in step S1, the graphite sand is cleaned for 3-8 times, and the drying temperature is 50-100°C.

[0033] S2 sand mixing

[0034] First, weigh a certain amount of cl...

Embodiment 1

[0047] (1) Clean graphite sand

[0048] (a) Put 100 mesh artificial granular graphite sand into water, the volume ratio of graphite sand to water is 1:1, then apply mechanical stirring, the stirring speed is 500rpm, stop stirring after stirring for 1h, and pour it out immediately after standing for 10s Water with graphite ash in the upper part.

[0049] (b) Wash 6 times according to the above steps until there is no graphite ash in the water, and dry at 60°C for later use.

[0050] (2) sand mixing

[0051] (a) First take by weighing a certain amount of cleaned graphite sand, resin binder and corresponding curing agent, the binder is furan resin, accounting for 5% of the graphite sand weight, and the curing agent is a curing agent for furan resin, accounting for 5% of the weight of the resin 50% by weight.

[0052] (b) Add the graphite sand into the sand mixer and start stirring. During the stirring process, add the curing agent first, and then add the resin binder after sti...

Embodiment 2

[0061] (1) Clean graphite sand

[0062] (a) Put 100 mesh artificial granular graphite sand into water, the volume ratio of graphite sand to water is 1:1, then apply mechanical stirring, the stirring speed is 500rpm, stop stirring after stirring for 1h, and pour it out immediately after standing for 10s Water with graphite ash in the upper part.

[0063] (b) Wash 6 times according to the above steps until there is no graphite ash in the water, and dry at 60°C for later use.

[0064] (2) sand mixing

[0065] (a) First take by weighing a certain amount of cleaned graphite sand, resin binder and corresponding curing agent, the binder is furan resin, accounting for 4% of the weight of graphite sand, and the curing agent is a curing agent for furan resin, accounting for 4% of the weight of the resin 60% by weight.

[0066] (b) Add the graphite sand into the sand mixer and start stirring. During the stirring process, add the curing agent first, and then add the resin binder after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com