Capacitive screen capable of removing dirt

A capacitive screen and sliding board technology, which is applied in the field of capacitive screens, can solve problems such as capacitive screen damage, time and energy consumption, residual fingerprints, etc., and achieve the effect of preventing capacitive screen damage and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

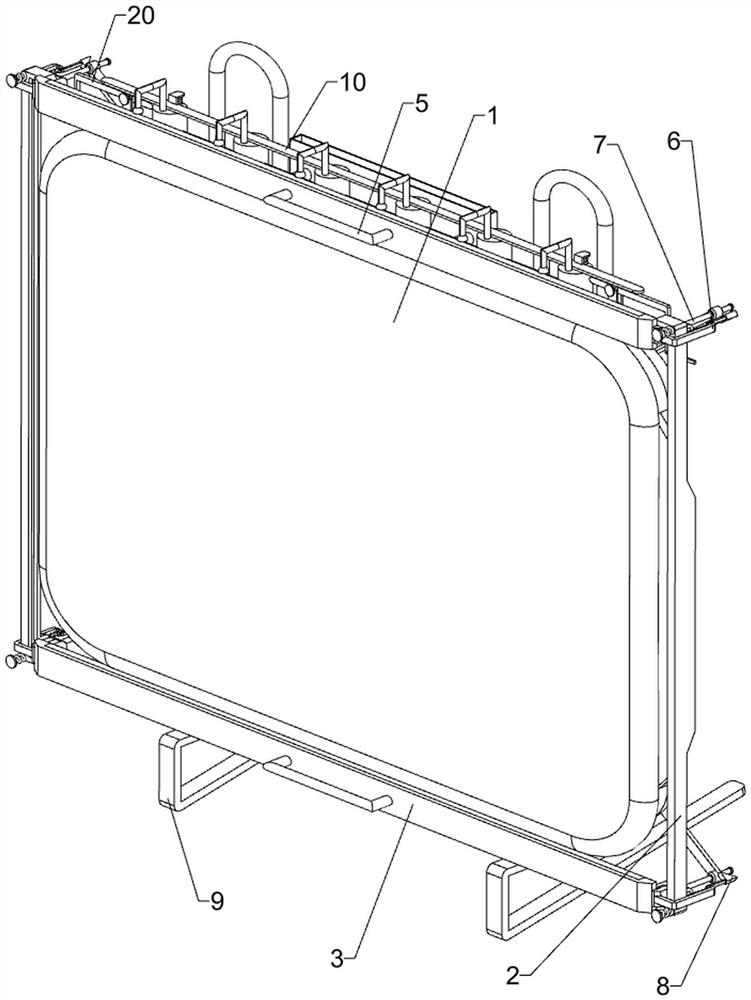

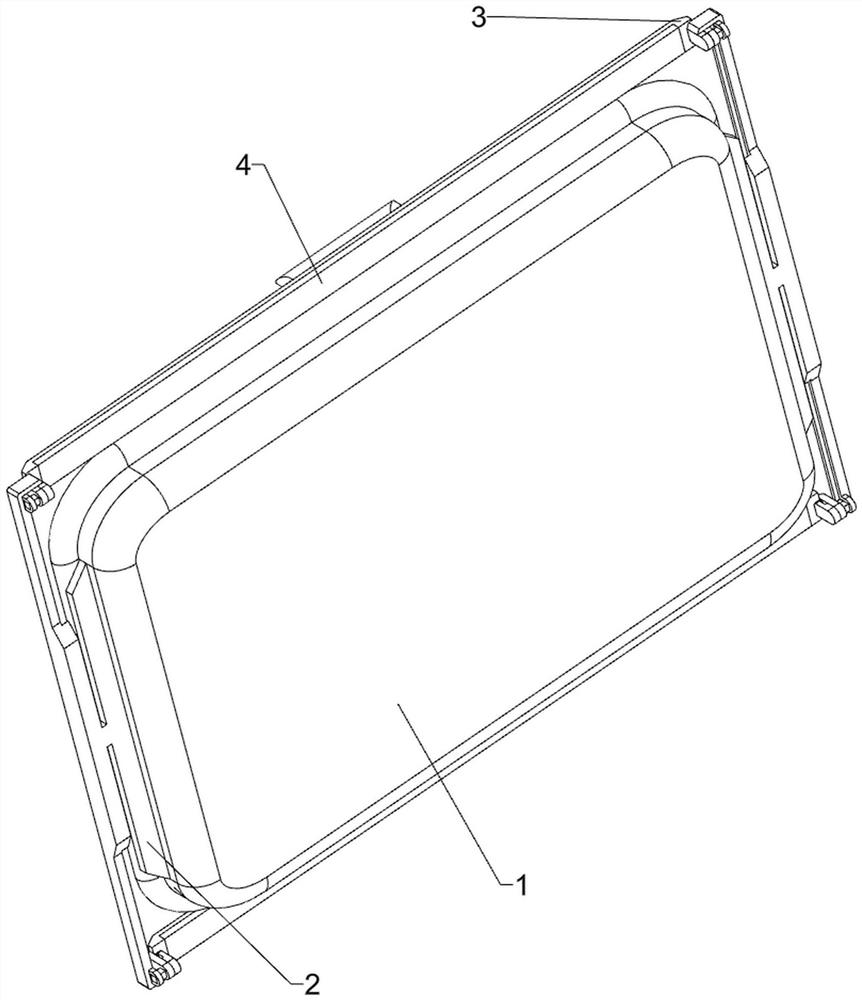

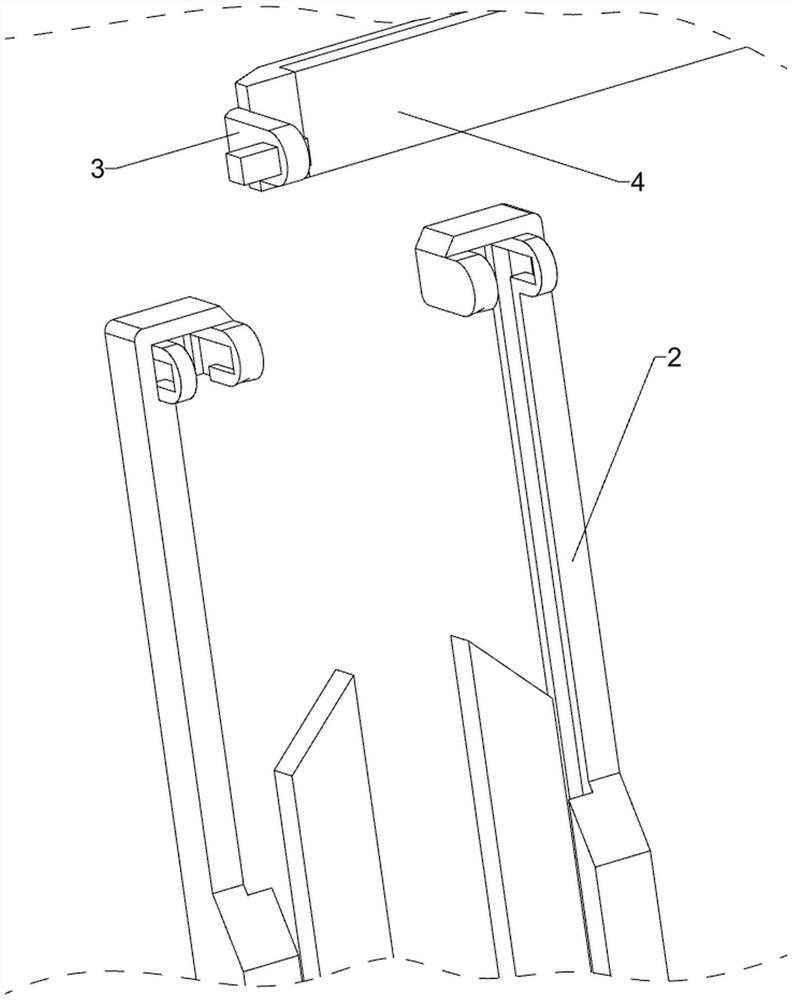

[0037] A decontamination capacitive screen such as Figure 1-4 As shown, it includes a capacitive screen 1, a mounting rail 2, a sliding plate 3, a wiping cotton 4, a pull rod 5 and a limiting assembly 6. The left and right sides of the capacitive screen 1 are connected to the mounting rail 2, and the upper and lower sides of the mounting rail 2 are connected to each other. Sliding plate 3 is evenly connected to each other, and the rear side of sliding plate 3 is equipped with wiping cotton 4, which is used to clean the surface of capacitive screen 1, and the front side of the middle part of sliding plate 3 is welded with pull rod 5 and mounting rail 2. A limiting component 6 is provided between the sliding plate 3 and the limiting component 6 is used for limiting the sliding plate 3 .

[0038] The limiting assembly 6 includes a connecting rod 61, a clamping rod 62 and a pressure spring 63. The left and right sides of the sliding plate 3 are connected with a connecting rod 61,...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 with Figure 17 As shown, a power assembly 7 is also included, and the power assembly 7 includes a telescopic swing rod 71, a sliding pull seat 72, a T-shaped telescopic rod 73, a winding wheel 74, a pull wire 75, an electric push rod 76, a V-shaped shrapnel 77 and connecting Rod 78, the middle rear side of the capacitive screen 1 is rotationally connected with four telescopic swing rods 71 according to the circumferential distribution, the middle rear side of the capacitive screen 1 is provided with four electric push rods 76 according to the circumferential distribution, and the electric push rods on the same side in the horizontal direction The telescopic rods of 76 are hingedly connected with T-shaped telescopic rods 73, and the rear side of the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com