Steady-state no-load test method for mechanical characteristics of motor

A technology of mechanical characteristics and no-load testing, applied in the direction of motor generator testing, etc., can solve the problems of difficulty in determining the capture accuracy of transient capture points and difficult to guarantee measurement accuracy, and achieve the effect of low test cost and convenient test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

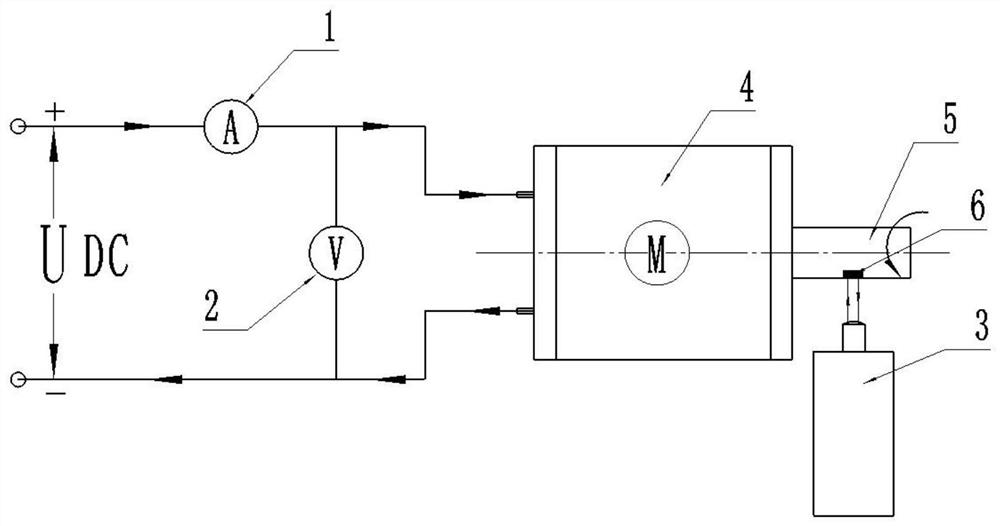

[0060] Embodiment: In this embodiment, a DC motor 4 to be tested is selected, and two sets of data are obtained by using a measuring device, that is, as figure 1 , the ammeter 1 is electrically connected with the motor 4 to be tested, the voltmeter 2 is electrically connected with the motor 4 to be tested, the contact of the rotational speed measuring instrument 3 is placed at the output shaft 5 of the motor, and placed on the output shaft 5 of the motor A reflective paper mark 6 is set on the top, and when the motor output shaft 5 rotates, the reflective paper mark 6 is convenient for the speed measuring instrument 3 to accurately collect the speed of the motor 4 to be tested;

[0061] In the first step S1, apply the rated voltage U to the motor 01 , until the motor runs to a steady state, measure the no-load current I of the motor 01 and no-load speed n 01 , that is, when the no-load speed n of the motor 01 When the change of the value tends to be stable, obtain the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com