Pipeline anti-disengaging connecting assembly

A technology for connecting components and pipes, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, through components, etc., can solve the problems of occupation, increase pipe cost, large capital and warehouse space, etc. Reduce maintenance costs and reduce warehouse space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

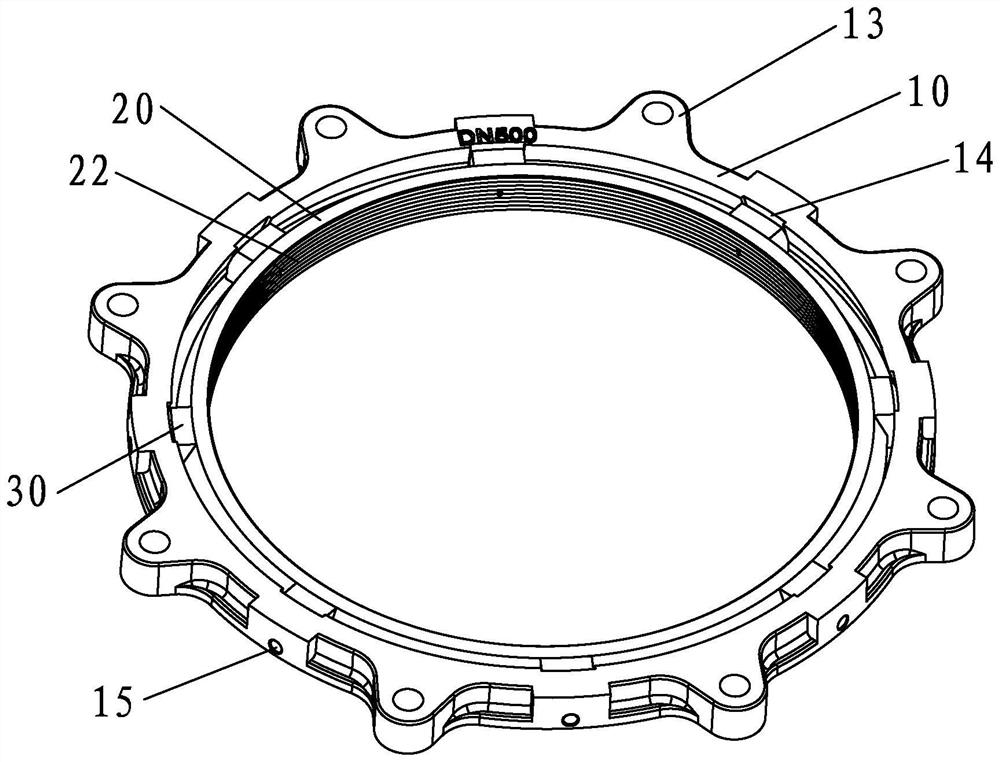

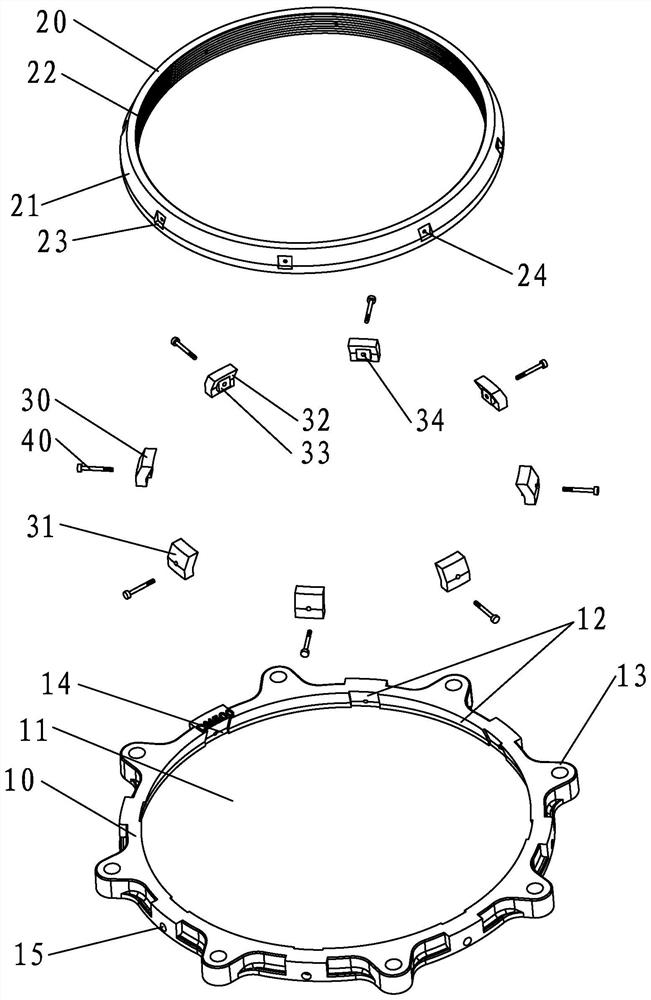

[0060] Such as Figure 1-Figure 2As shown, the present embodiment provides a pipeline anti-disengagement connection assembly, including a gland 10, the gland 10 has a perforation 11, and the inner sidewall of the perforation 11 has a diameter (when its cross section is circular) or a profile diameter (when its cross section is circular) When the cross-section is non-circular), the inclined guide surface 12 gradually decreases from one end to the other end of the through-hole 11 . In this embodiment, the cross-section of the through-hole 11 is circular as an example for illustration. An anti-off ring 20 is arranged in the perforation 11 , and a plurality of adjusting blocks 30 around the axis of the gland 10 are arranged between the anti-off ring 20 and the gland 10 . During use, the pipeline is inserted in the anti-off ring 20 .

[0061] The outer periphery of the gland 10 is provided with a plurality of lugs 13 evenly distributed around the axis of the gland 10, and the lugs...

Embodiment 2

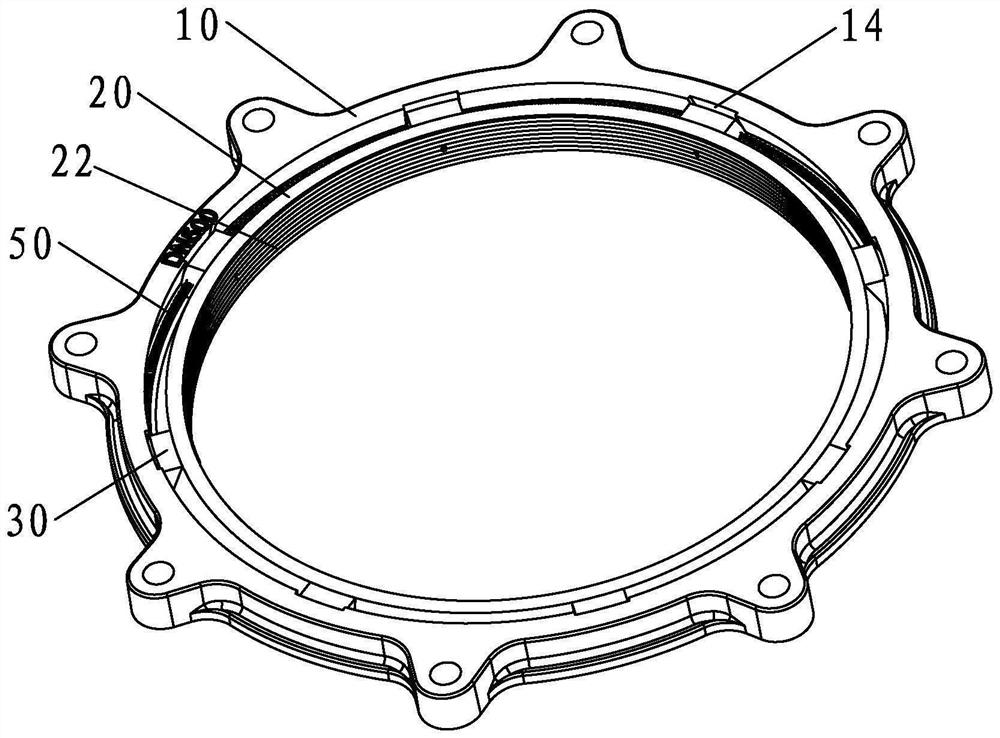

[0069] Such as image 3 shown, and refer to figure 1 and figure 2 As shown, the difference between the anti-disengagement connection assembly provided in this embodiment and the first embodiment is that, in this embodiment, a connecting unit 50 is provided between two adjacent adjustment blocks 30 . The connection unit 50 may be the connection unit used in the fourth embodiment, the fifth embodiment or the sixth embodiment mentioned below, of course, it may be necessary to provide a corresponding matching structure on the adjustment block 30 .

[0070] By setting the connecting unit, each adjusting block 30 can be connected in series in advance to form a ring, so as to avoid loss during use.

Embodiment 3

[0072] Such as Figure 4 shown, and refer to figure 1 and figure 2 As shown, the difference between the anti-off connection assembly provided in this embodiment and the first or second embodiment is that the structure of the anti-off ring 20 is different. Specifically, in this embodiment, the anti-off ring 20 includes a plurality of The adjustment block 30 is arranged in a one-to-one correspondence with the anti-off block 25, and the side of the anti-off block away from the gland 10 has an inclined arrangement from the axial end of the anti-off ring 20 to the other end and gradually away from the gland 10. The inclined push surface 21 and the matching structure of the inclined push surface 21 and the adjusting block 30 are the same as those in the first embodiment, and will not be repeated here.

[0073] This embodiment mainly replaces the ring-shaped ring body in Embodiment 1 or Embodiment 2 with a plurality of anti-off blocks 25, so that when it is necessary to install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com