Zero-pressure-sensing high-elasticity fluffy cotton air layer fabric and preparation method thereof

An air layer, fluffy cotton technology, applied in the direction of dyeing, fabric surface trimming, heating/cooling fabrics, etc., can solve problems such as increased gram weight, increased fabric heaviness, and poor shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

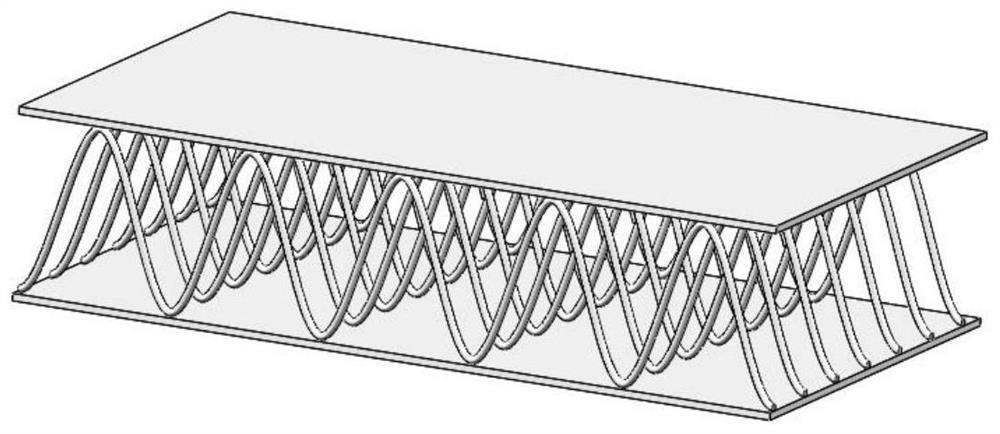

[0028] Such as Figure 1-3 As shown, the present embodiment provides a zero-pressure-sensitive high-elastic fluffy cotton air layer fabric, the fabric is an air layer structure, and the fabric includes an outer layer, a connecting layer and an inner layer, and the outer layer and the inner layer the layers are connected by the connection layer;

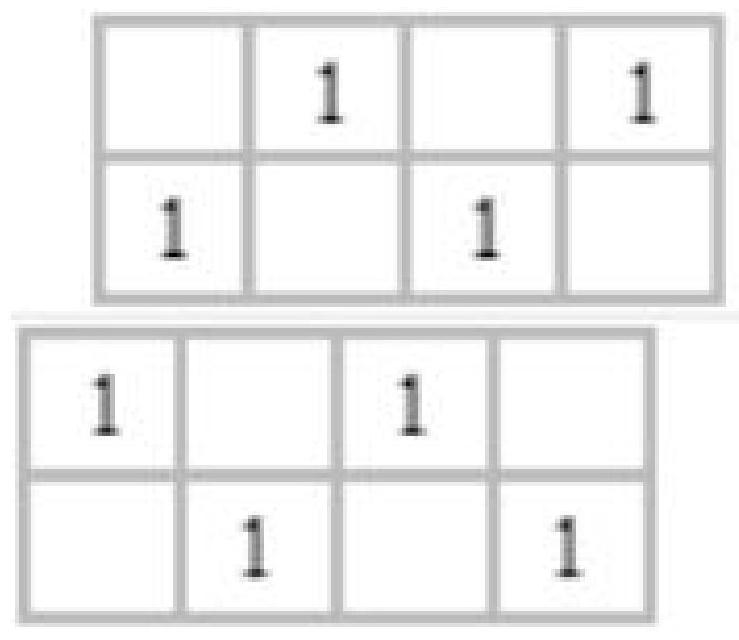

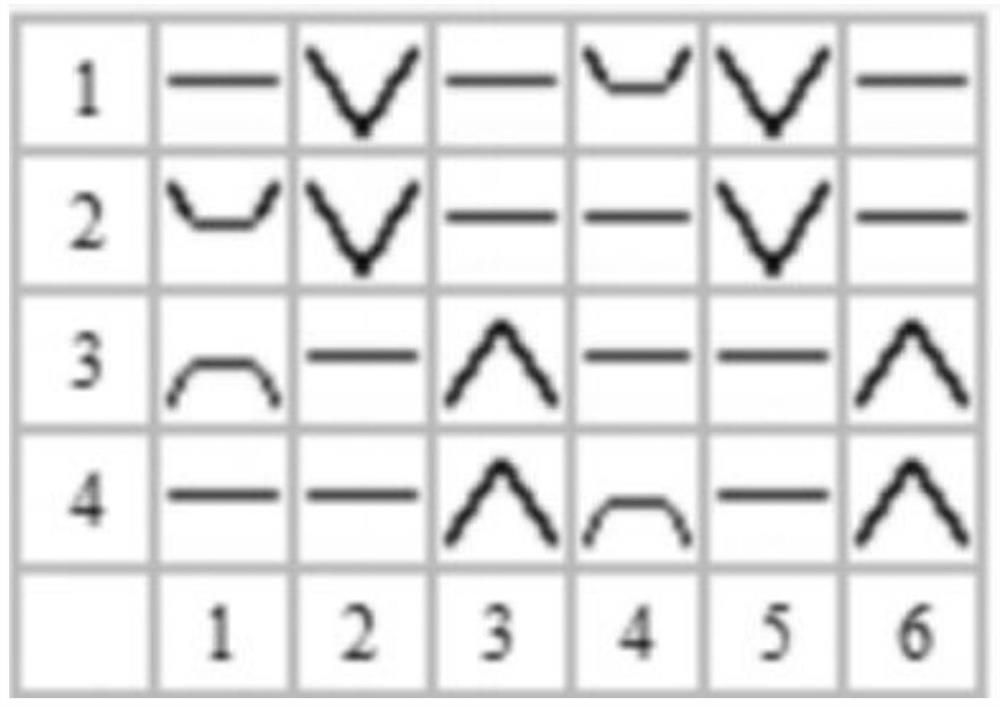

[0029] The arrangement of knitting needles when the fabric is knitted is that the upper dial AB is arranged sequentially, and the lower dial BA is arranged sequentially, wherein A represents a high-heel needle, and B represents a low-heel needle; All the high clock needles in the first road form a connecting layer in the form of tucks, connecting the outer layer and the inner layer; all the knitting needles on the second road dial work to form the inner layer in the form of loops; the third lower needle cylinder All knitting needles participate in work to form the outer layer in the form of loops; all the low clock needles in the fou...

Embodiment 2

[0035] This embodiment provides a method for preparing a zero-pressure high-elasticity fluffy cotton air-layer fabric. The steps include: gray fabric, presetting, pretreatment, dyeing, dehydration, width cutting, shaping, inspection, and packaging.

[0036] As a preferred embodiment, in the presetting step, the temperature is 180°C, the vehicle speed is 30m / min, and the grammage is 260g / m 2 , the door width is 155cm.

[0037] As a preferred embodiment, in the dyeing step, the technological process sequentially includes: wetting with warm water, dyeing, gradual temperature rise dyeing, heat preservation dyeing, reduction cleaning, water washing, and cloth discharging.

[0038] As a preferred embodiment, in the dyeing step, the specific process steps are: put the gray cloth in a dyeing pool at 60°C, raise it to 80°C at a rate of 2°C / min for 5 minutes, then heat it at a rate of 1°C / min After the speed rises to 100°C for 5 minutes, then rises to 130°C at a speed of 1.5°C / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com