All-terrain locomotive moving system with anti-puncture protection function

A mobile system and all-terrain technology, applied to wheels, workshop equipment, household appliances, etc., can solve problems that affect the service life of tires, tire punctures, etc., and achieve the effects of increasing service life, improving experience, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

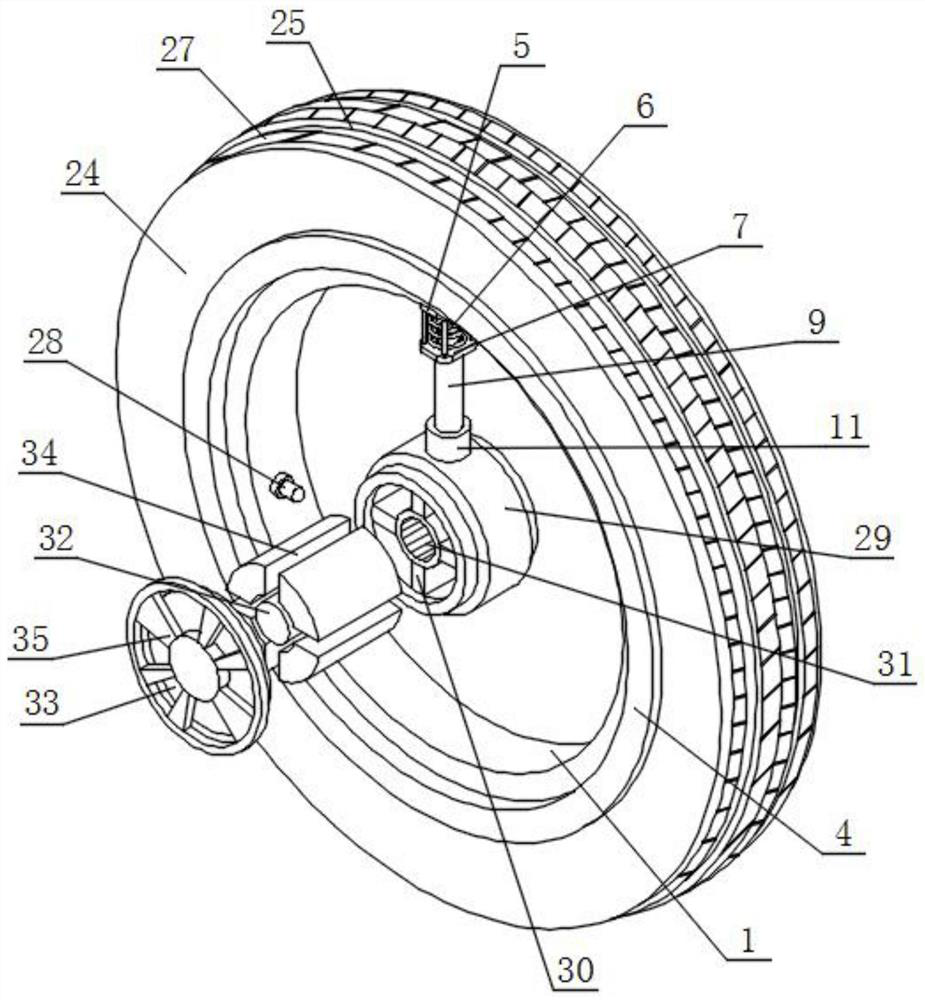

[0043] Such as image 3 and Figure 6 As shown, an all-terrain locomotive mobile system with anti-puncture protection includes a rim 1, a fixed block 2, a tire pressure sensor 3 and a retaining ring 4, and the inner wall of the rim 1 is equipped with six groups of fixed blocks 2 arranged equidistantly;

[0044] Specifically, the rim 1 and the retaining ring 4 are part of the hub structure of the tire, used to support the installation of the rubber tire, and the fixed block 2 is used as the starting position of the spoke in the mobile wheel member, which provides a relatively stable the installation location.

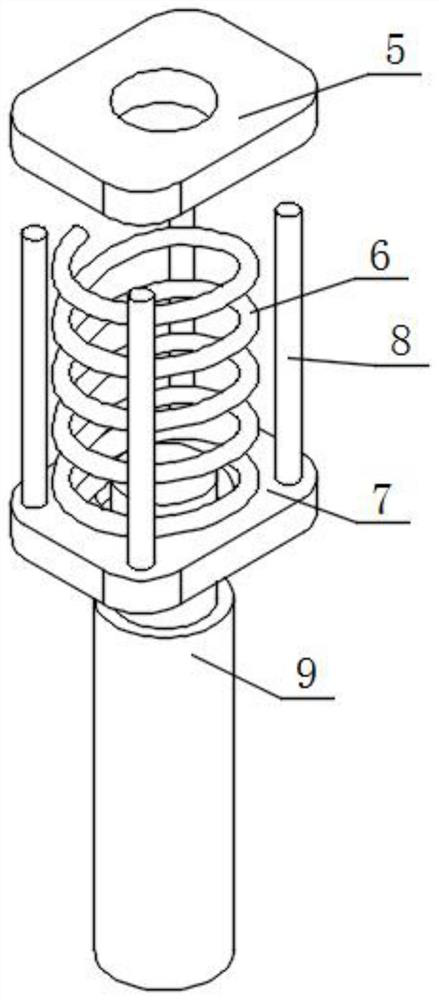

[0045] The bottom of the fixed block 2 is equipped with an assembly plate one 5, and the bottom of the assembly plate one 5 is equipped with a telescopic spring 6, and the bottom of the telescopic spring 6 is equipped with an assembly plate two 7, and the bottom of the assembly plate one 5 is equipped with four groups of equidistantly arranged circles. Rod 8, and the b...

Embodiment 2

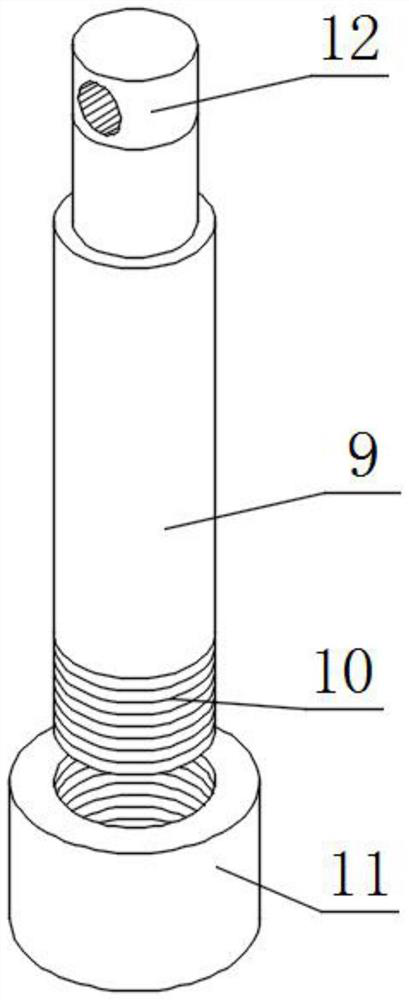

[0048] Such as figure 2 and Figure 4 As shown, the bottom of the electric telescopic rod 9 is equipped with a threaded column 10, the outer surface of the threaded column 10 is equipped with a threaded sleeve 11, and the top of the electric telescopic rod 9 is equipped with a connecting column 12, and the outer wall of the connecting column 12 is connected to the fixed block 2 The inner wall fits.

[0049] Specifically, the threads provided on the outer surface of the threaded post 10 can match the threads inside the threaded sleeve 11, thereby facilitating the detachable connection between the threaded post 10 and the threaded sleeve 11, and the outer surface of the connecting post 12 is provided with a groove hole, and the diameter of this slot is the same as the diameter of the miniature electric push rod 15, when the integrated length of the electric telescopic rod 9 is adjusted to the longest state, when the miniature electric push rod 15 is extended outward, one end c...

Embodiment 3

[0053] Such as Figure 5 and Figure 7 As shown, the outer wall of the rim 1 is equipped with a tire pressure sensor 3, and the outer wall of the rim 1 is installed with two sets of retaining rings 4 arranged in front and rear, and the two sets of retaining rings 4 are respectively located in front of and behind the tire pressure sensor 3, and the tire pressure sensor 3 A through groove is arranged on the top of the through groove, a fixed rod 16 is installed on the inner wall of the through groove, a movable sleeve 17 is installed on the outer surface of the fixed rod 16, and a probe rod 18 is installed on the bottom of the movable sleeve 17, and the bottom of the probe rod 18 runs through the rim 1 Inside, a temperature sensor 19 is installed on one side of the outer wall of the tire pressure sensor 3 .

[0054] Specifically, the tire pressure sensor 3 can detect the pressure value inside the mobile wheel in real time, and then transmit the monitored data to the central rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com