High-efficiency demolding device for injection molding processing of automotive upholstery

A technology for injection molding of automotive interior parts, applied in the field of high-efficiency demoulding devices for injection molding of automotive interior parts, which can solve problems such as shaking of the top block, affecting processing operations, and no demoulding effect, so as to achieve stability of the lower mold , Reduce power consumption, not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

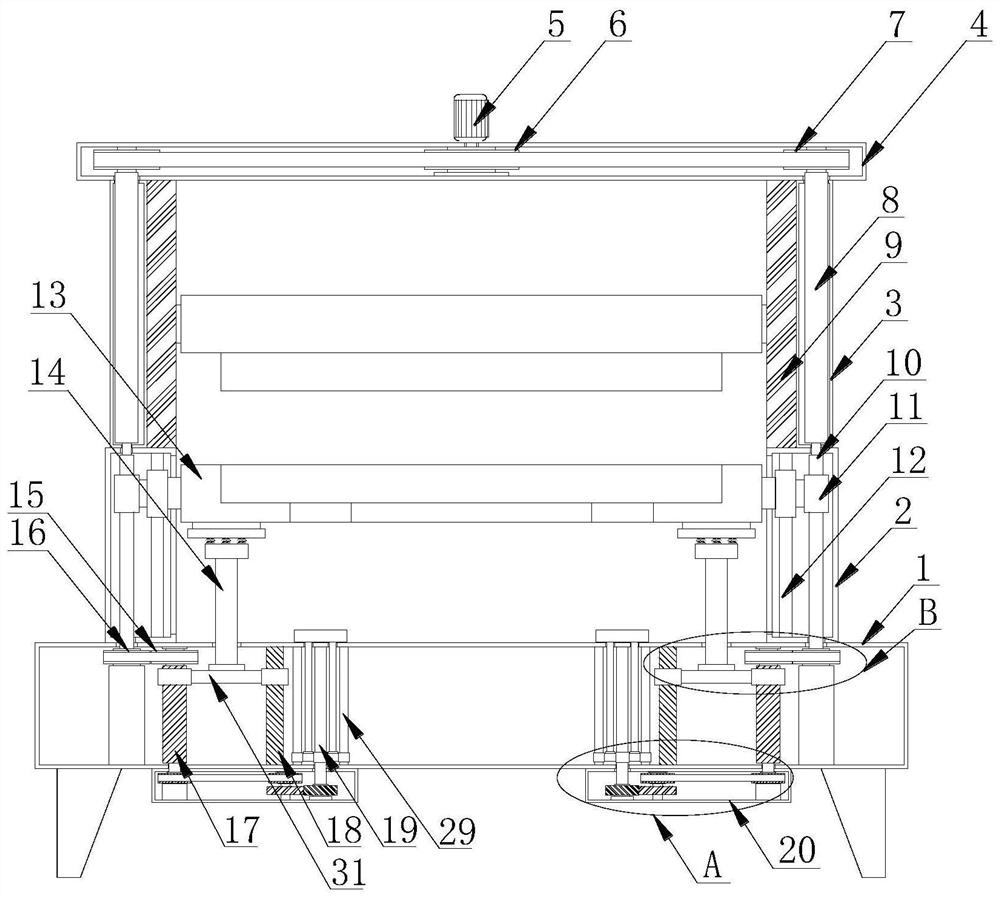

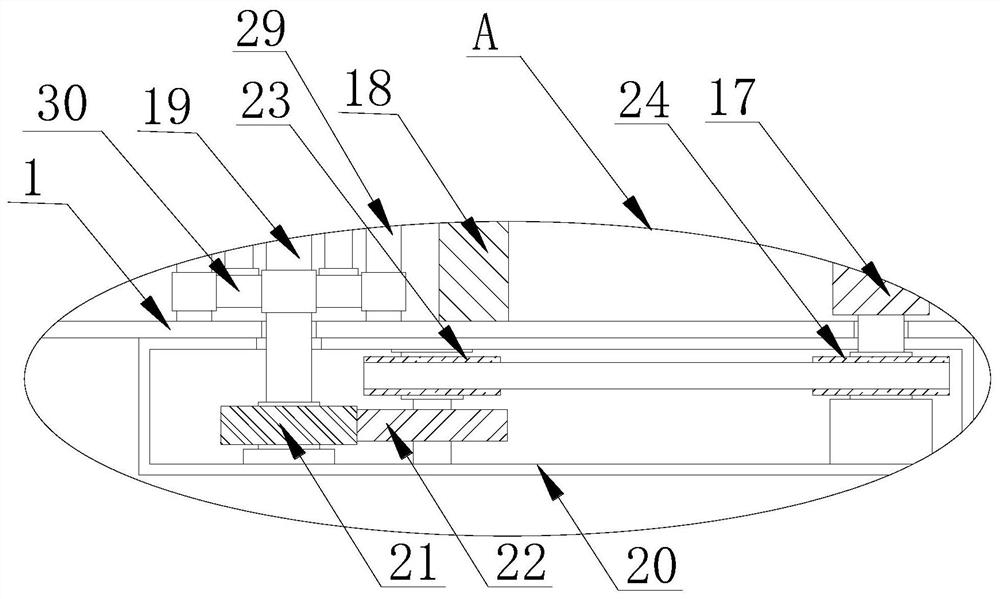

[0027] see Figure 1-4 , this embodiment provides a building formwork transmission device with adjustable spacing, including a fixed base 1, and two lifting mechanisms 25 are symmetrically arranged inside the fixed base 1, and two fixed boxes are symmetrically fixedly connected to the bottom of the fixed base 1 20. The insides of the two fixed boxes 20 are equipped with a rotating mechanism 26, and the top of the fixed base 1 is symmetrically fixedly connected with two supporting columns 2, and the interior of the two supporting columns 2 is equipped with a moving mechanism 27, and the two supporting columns 2 The top ends of the two support rods 3 are fixedly connected with a support rod 3, and the top ends of the two support rods 3 are fixedly connected with a top plate 4, and a rotating mechanism 28 is arranged inside the top plate 4.

[0028] Most of the existing demoulding mechanisms do not have a good demoulding effect. When heavy objects need to be demoulded, incomplete...

Embodiment 2

[0036] see figure 1 Or 5, made further improvement on the basis of embodiment 1:

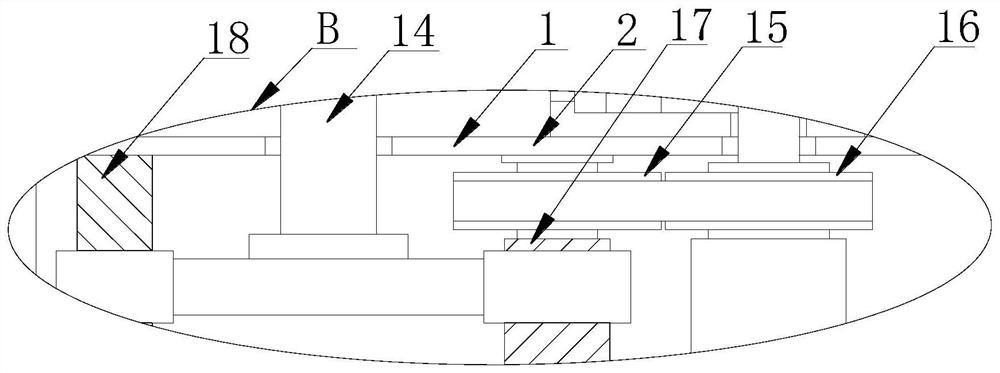

[0037] In order to make the lower mold 13 more stable when lifting and lowering, the moving mechanism 27 includes a first threaded rod 10, the bottom end of the first threaded rod 10 runs through the fixed base 1, and the bottom end of the first threaded rod 10 is welded. Drive plate 16 is arranged, and the top end of the first threaded rod 10 is welded with connector, and the end of connector away from the first threaded rod 10 runs through support rod 3 and is welded with rotating rod 8, and the first threaded rod 10 is near the center of top plate 4. The side is provided with a fixed rod 12, the fixed rod 12 is welded in the support column 2, the fixed rod 12 is provided with a movable block, and the movable block is slidably connected to the fixed rod 12, and the first threaded rod 10 is provided with a lifting block 11, which can be lifted The block 11 is screwed on the first threaded rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com