Electric joint module integrating control of double speed reducers

A technology of double deceleration and harmonic reducer, which is applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve the problems of large harmonic bearing load, failure to guarantee the safety and reliability of robots, and failure to meet the requirements of robot motion power. The effect of large output torque and high reliability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe in detail the embodiments of the present invention and their beneficial effects in conjunction with the accompanying drawings.

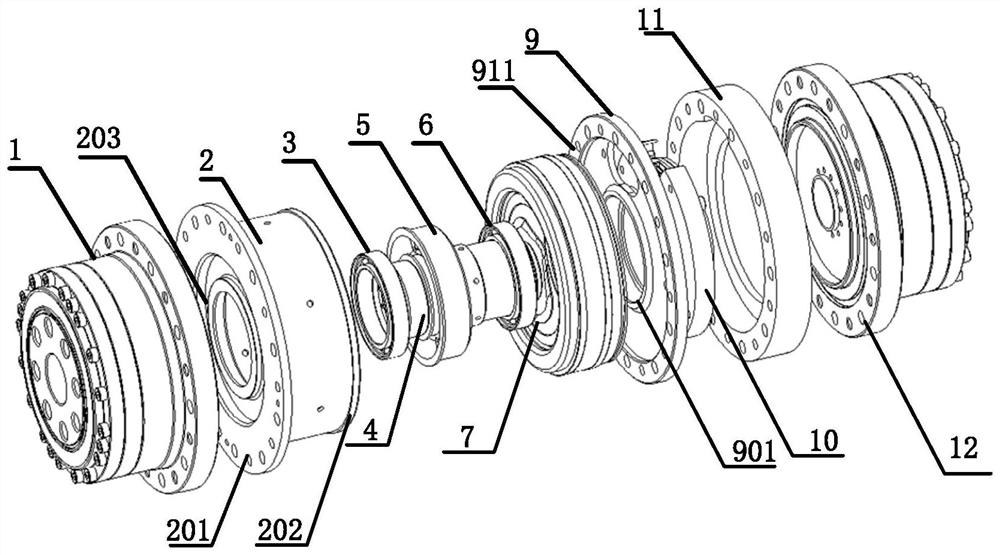

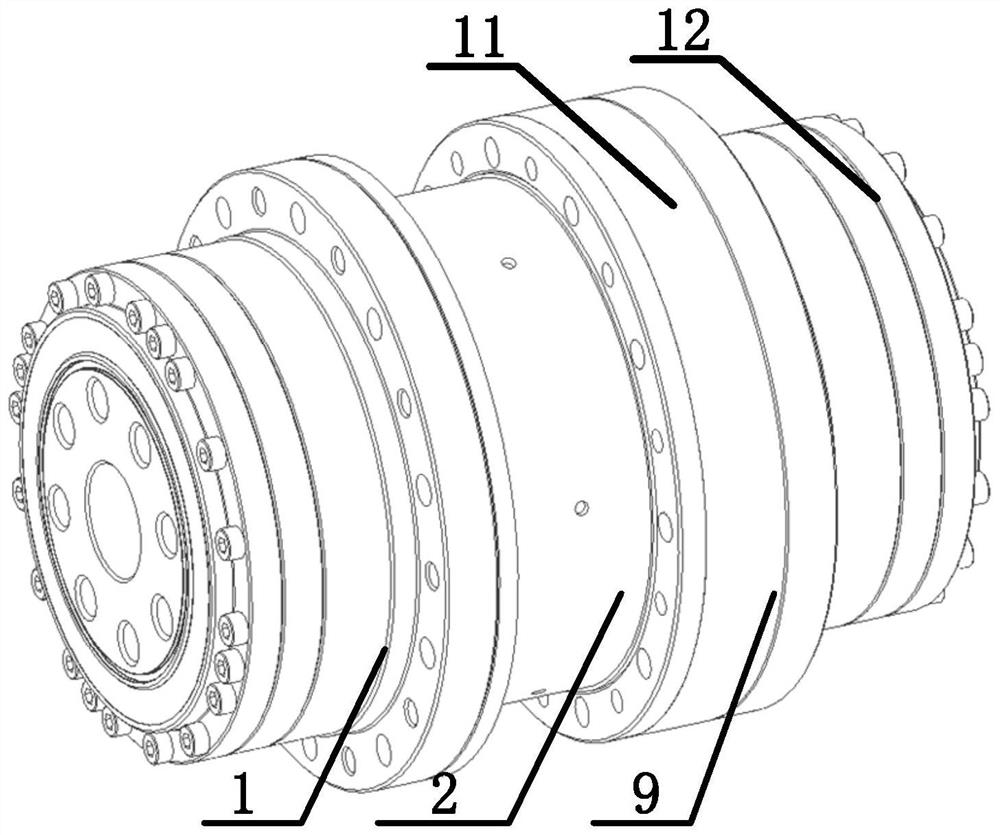

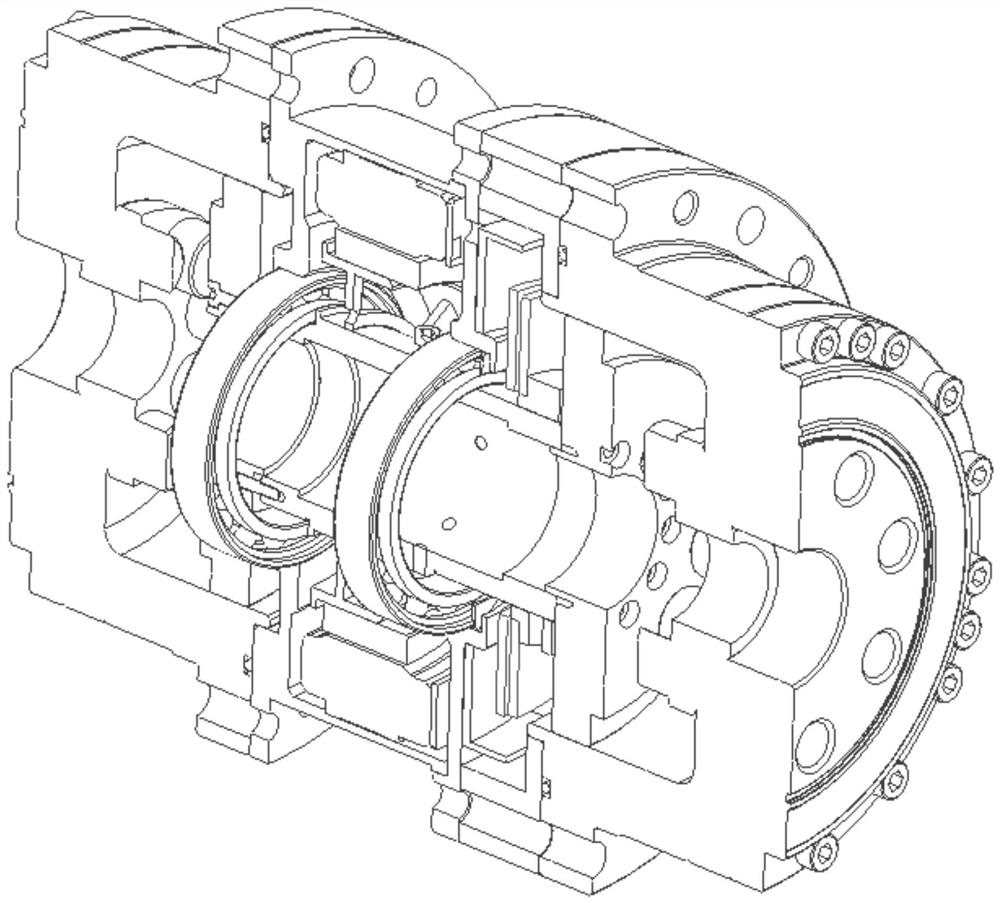

[0023] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention provides an electric joint module integrated with double reducer control, including: a joint housing 2, and the two axial ends of the joint housing 2 are respectively provided with a first mounting end 201 and a second mounting end 201 The second installation end 202; the first harmonic reducer 1 is fixedly connected to the first installation end 201; the frameless motor 8 is arranged in the joint housing 2, and the outer stator of the frameless motor 8 is fixedly connected to the inner wall of the joint housing 2; The motor end cover 9 is fixedly connected with the second mounting end 202; the support bracket 11 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com