Zoom laser processing system and method based on variable light spot diffraction element

A laser processing method and technology of diffractive elements, which are applied in the field of laser processing, can solve problems such as enlarged equipment size, unsuitable laser processing equipment, and increased length of laser processing equipment, so as to avoid lens aberration, reduce structural size, and reduce chromatic aberration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

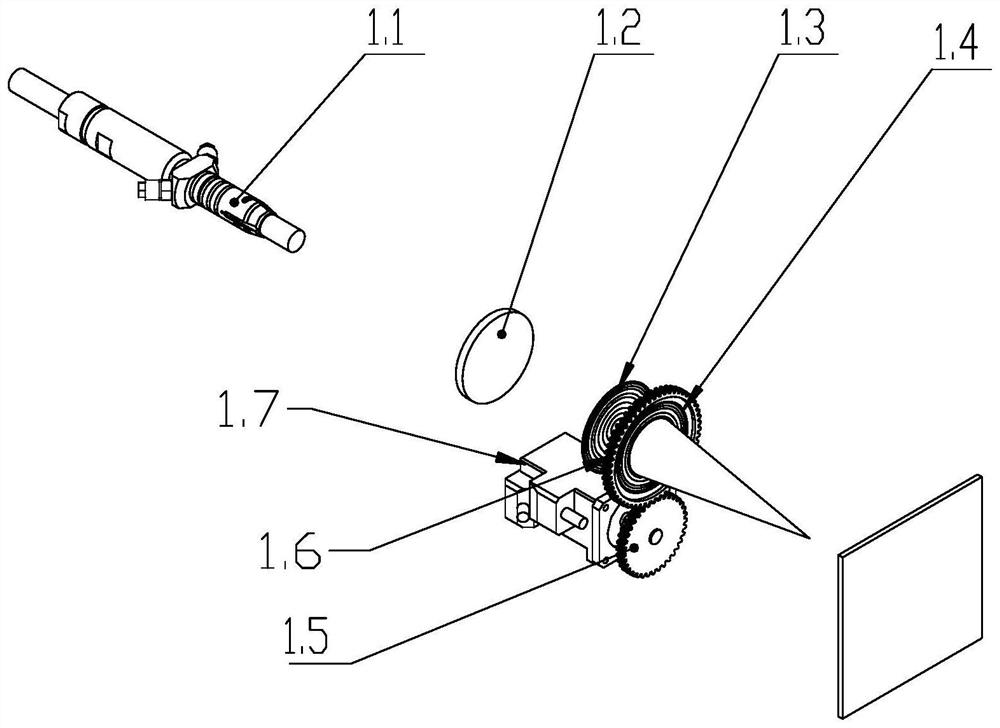

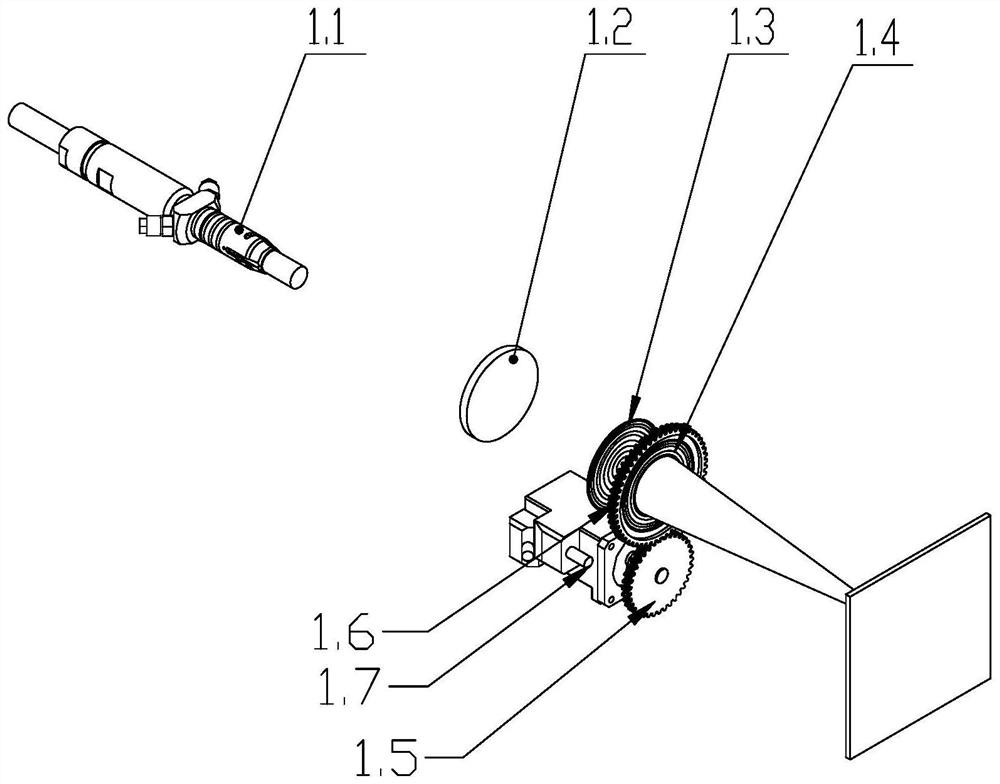

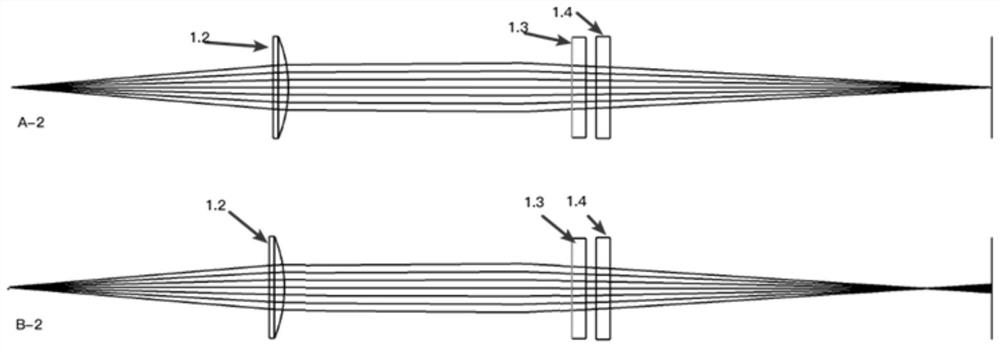

[0060] refer to figure 1 and 2 , this embodiment discloses a zoom laser processing system based on a variable spot diffraction element, including a laser 1.1 for generating laser light, a collimator lens 1.2 for changing the light path, and a diffractive optical element module for controlling the focus distribution of the spot, The collimating lens 1.2 is placed between the laser 1.1 and the diffractive optical element module, and the laser light emitted by the laser 1.1 is irradiated onto the diffractive optical element module through the collimating lens 1.2, and passes through the diffractive optical element The laser beam focused by the module is irradiated onto the workpiece to be processed, and the diffractive optical element module is used to control the focal power of the DOE lens and the focus distribution of the laser light, so that the focal point generated by the diffractive optical element module moves along a predetermined processing track to Complete the proces...

Embodiment 2

[0075] This embodiment only describes the differences from the above embodiments. In this embodiment, the drive shaft of the rotating drive motor 1.7 is connected to more than two driving gears 1.5, and the number of teeth and diameters of multiple driving gears 1.5 can be the same or different. Similarly, the rotation driving motor 1.7 drives one or more driving driving gears 1.5 to rotate, so that the driven driving gear 1.6 meshing with the driving driving gear 1.5 rotates at the same or different angles. In this embodiment, a diffractive optical element module composed of three or more DOE lenses can be constructed.

Embodiment 3

[0077] This embodiment discloses based on the same inventive concept, and the second purpose of the present invention is to provide a zoom laser processing method based on a variable spot diffraction element, including the following steps:

[0078] S1. Select a laser for generating laser light, a collimating lens for changing the light path, and a diffractive optical element module for controlling the focus distribution of the spot, and place the collimating lens between the laser and the diffractive optical element module , selecting different characteristic functions according to its lens array size, pixel size and zoom interval to set the lens profile function of the DOE lens;

[0079] S2. The diffractive optical element module selects at least two DOE lenses that are relatively distributed in the axial direction and a rotating drive that drives the DOE lenses to rotate, and at least one of the DOE lenses is driven by the rotating drive to capture the light of the DOE lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com