Plastic particle drying equipment

A technology for drying equipment and plastic granules, which is applied in drying, dryers, and drying of granular materials. It can solve the problems of insufficient drying time for plastic granules, uneven drying temperature, and sticky plastic granules, and achieve improved Drying effect, improved filtering effect, improved drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

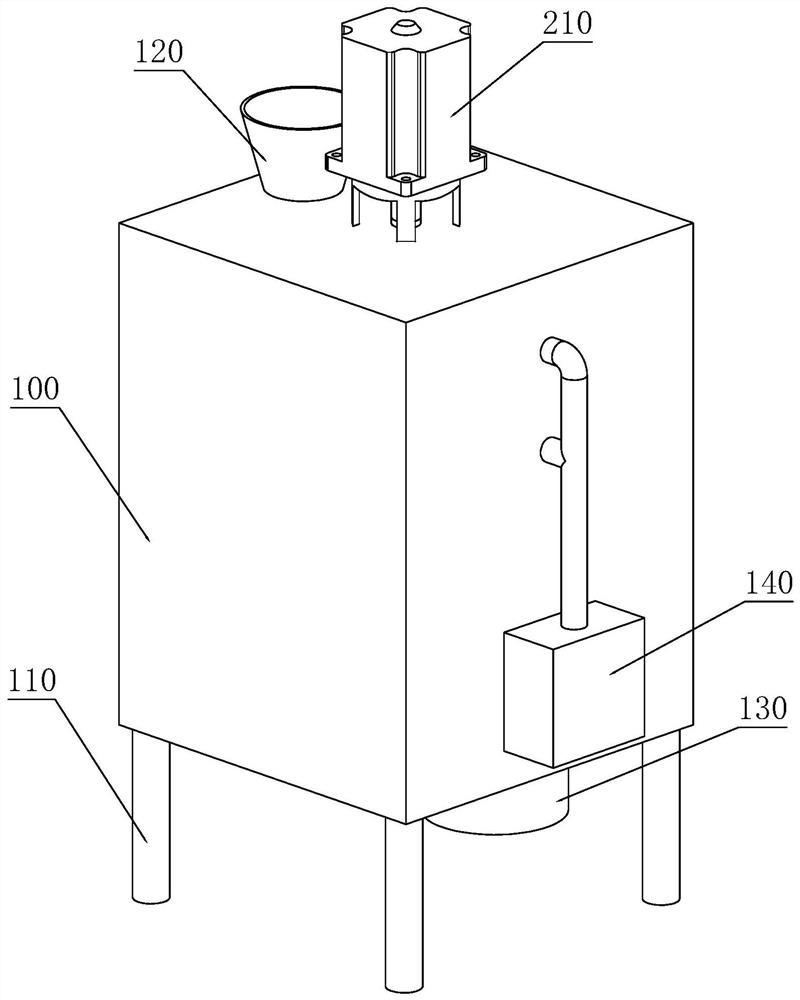

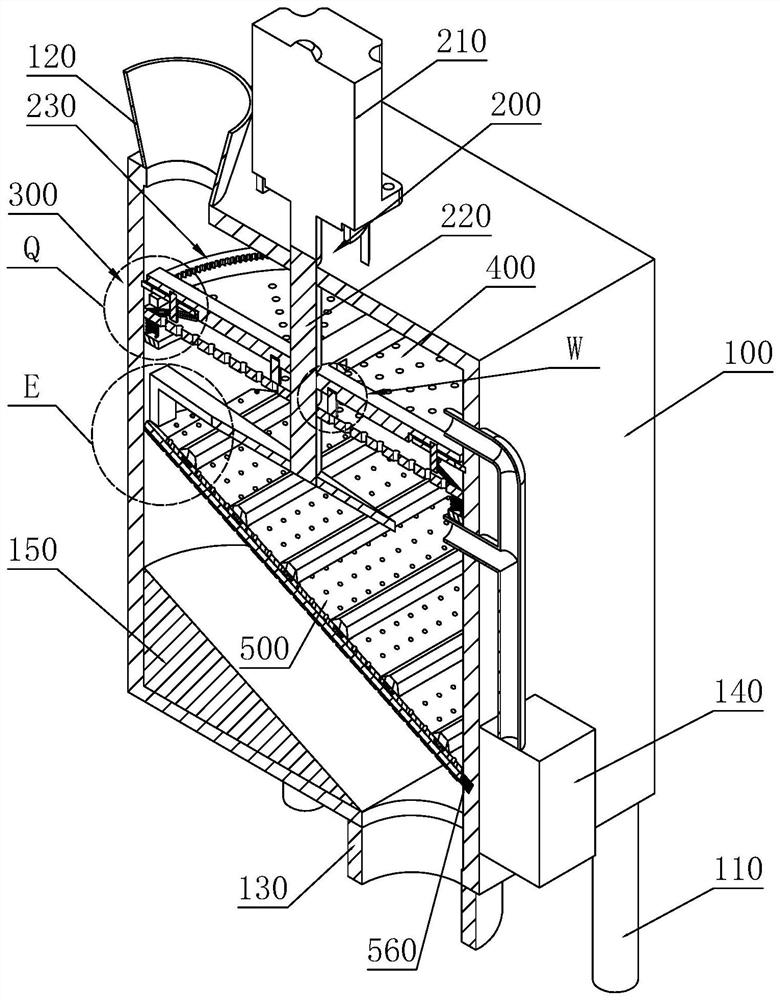

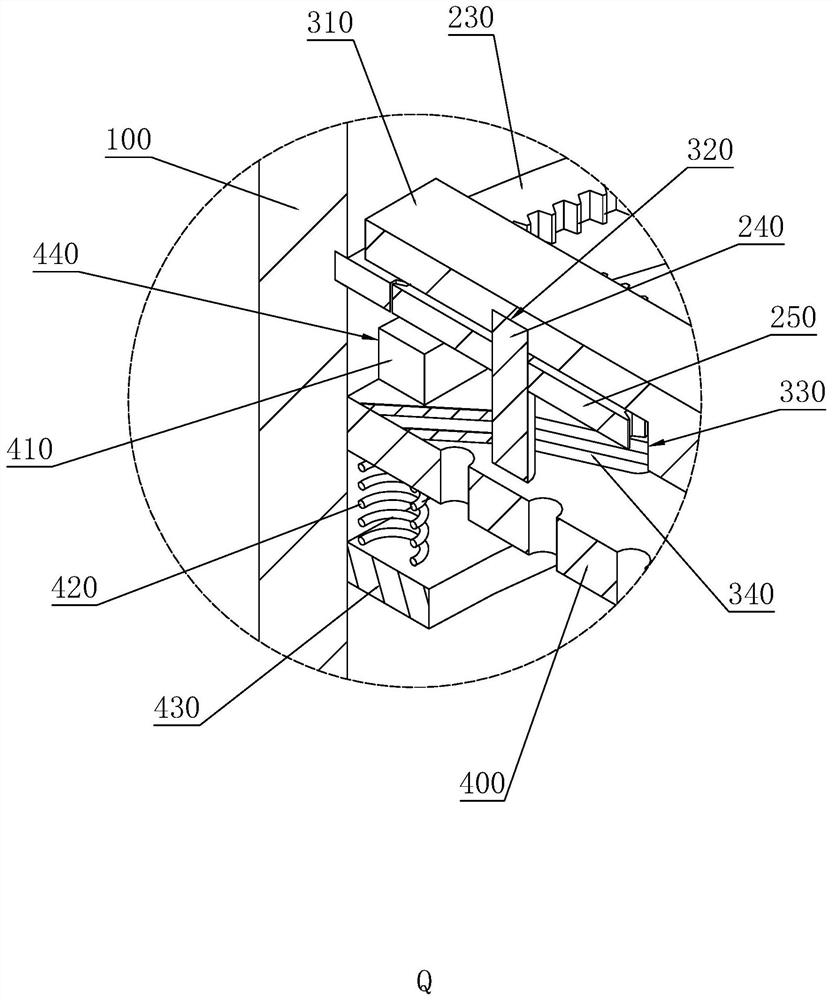

[0037] The following is attached Figure 1-7 The application is described in further detail. The embodiment of the present application discloses a drying equipment for plastic particles. refer tofigure 1 and figure 2 , a drying equipment for plastic particles includes a barrel 100 , a hot air blower 140 , a first sieve plate 400 and a second sieve plate 500 . Wherein, the bottom surface of the barrel 100 is provided with four legs 110, and the four legs are respectively fixedly connected to four fixed points on the bottom surface of the barrel 100. A cavity is opened inside the machine barrel 100 , and a feeding hopper 120 is arranged on the upper surface of the machine barrel 100 , and the feeding hopper 120 communicates with the cavity of the machine barrel 100 . A discharge hopper 130 is provided on the lower surface of the machine barrel 100 , and the discharge hopper 130 communicates with the cavity of the machine barrel 100 . The first sieve plate 400 and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com