Low-solid-phase high-temperature-resistant salt-resistant completion fluid as well as preparation method and application thereof

A technology with high temperature resistance and low solid phase, applied in chemical instruments and methods, drilling compositions, etc., can solve problems affecting cementing quality, poor cement compatibility, complex chemical composition, etc., to improve heat resistance and salt resistance stability non-toxic, pollution-reducing, and low-consumption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

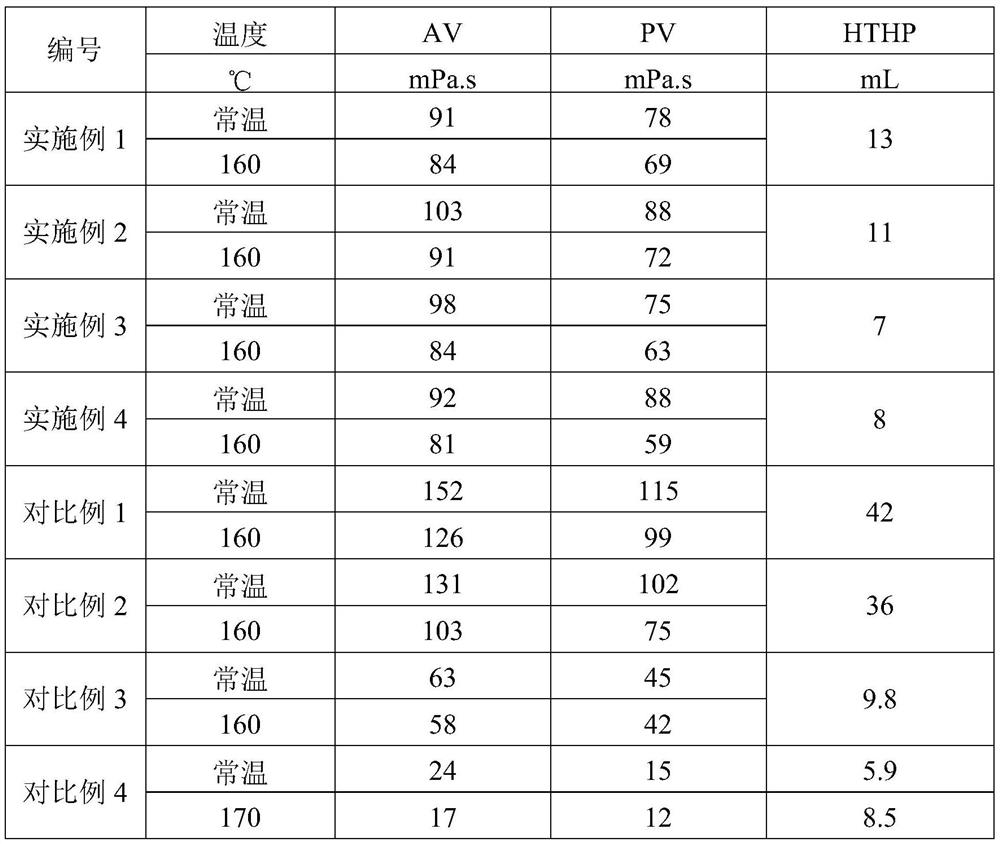

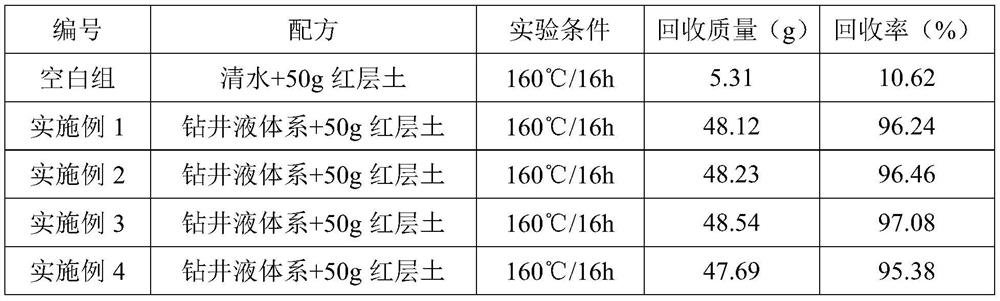

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a method for preparing the above-mentioned low-solid-phase, high-temperature, and salt-resistant completion fluid, the preparation method comprising:

[0043] Water, bentonite, potassium formate, high temperature resistant viscosifier, high temperature resistant fluid loss reducer, oil reservoir protection agent, flow pattern regulator and high temperature stabilizer are evenly mixed to obtain the low solid phase high temperature resistant and salt resistant well completion fluid.

[0044] According to the present invention, in a specific embodiment, the preparation method of the above-mentioned low-solid-phase, high-temperature, and salt-resistant completion fluid includes:

[0045] Add bentonite to the water first, then potassium formate, then add high temperature resistant viscosifier, then add high temperature resistant fluid loss reducer, then add oil layer protective agent, then add flow pattern regulator, then ad...

Embodiment 1

[0051] The invention provides a low-solid-phase, high-temperature, and salt-resistant completion fluid and a preparation method thereof.

[0052] First add 3 parts by weight of bentonite to 100 parts by weight of water, then add 10 parts by weight of potassium formate, then add 1 part by weight of anti-high temperature tackifier xanthan gum, and then add 2 parts by weight of anti-high temperature fluid loss reducer sulfur Methyl phenolic resin SMP-Ⅱ, plus 1 part by weight of oil reservoir protection agent FZD-1, plus 1 part by weight of flow regulator, zwitterionic polymer viscosity reducer XY-27, plus 1 part by weight of high temperature stable Agent CMC-LV, mixed evenly to obtain a low-solid, high-temperature, and salt-resistant completion fluid.

Embodiment 2

[0054] The invention provides a low-solid-phase, high-temperature, and salt-resistant completion fluid and a preparation method thereof.

[0055] First add 3 parts by weight of bentonite to 100 parts by weight of water, then add 3 parts by weight of bentonite, then add 50 parts by weight of potassium formate, then add 5 parts by weight of anti-high temperature tackifier xanthan gum, then add 5 parts by weight of The anti-high temperature fluid loss reducer sulfomethyl phenolic resin SMP-Ⅱ, plus 3 parts by weight of oil layer protection agent FZD-1, plus 5 parts by weight of flow regulator zwitterionic polymer viscosity reducer XY-27, Add 3 parts by weight of high-temperature stabilizer CMC-LV, and mix evenly to obtain a low-solid-phase, high-temperature, and salt-resistant completion fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com