Green coating method based on heavy-metal-free tanned cow crust leather

A heavy metal and crust leather technology, which is applied in the field of tanning, can solve the problems of poor adhesion between the coating and the crust leather, and the water absorption of the non-heavy metal tanned cow leather is reduced, so as to impart water and oil repellency and improve the hydrophobicity of the coating Good performance, heat resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of green finishing method based on non-heavy metal tanned cow leather, comprises the steps:

[0037] Step 1. Preparation of pre-primer coating agent

[0038] 260 parts by weight of water, 100 parts by weight of aromatic polyurethane resin dispersion Unires RU-43-989 (Staler Fine Coatings (Suzhou) Co., Ltd.), aliphatic polyurethane resin dispersion Unires RU-3904 (Staler Fine Coatings (Suzhou) Co., Ltd. Suzhou) Co., Ltd.) 40 parts by weight.

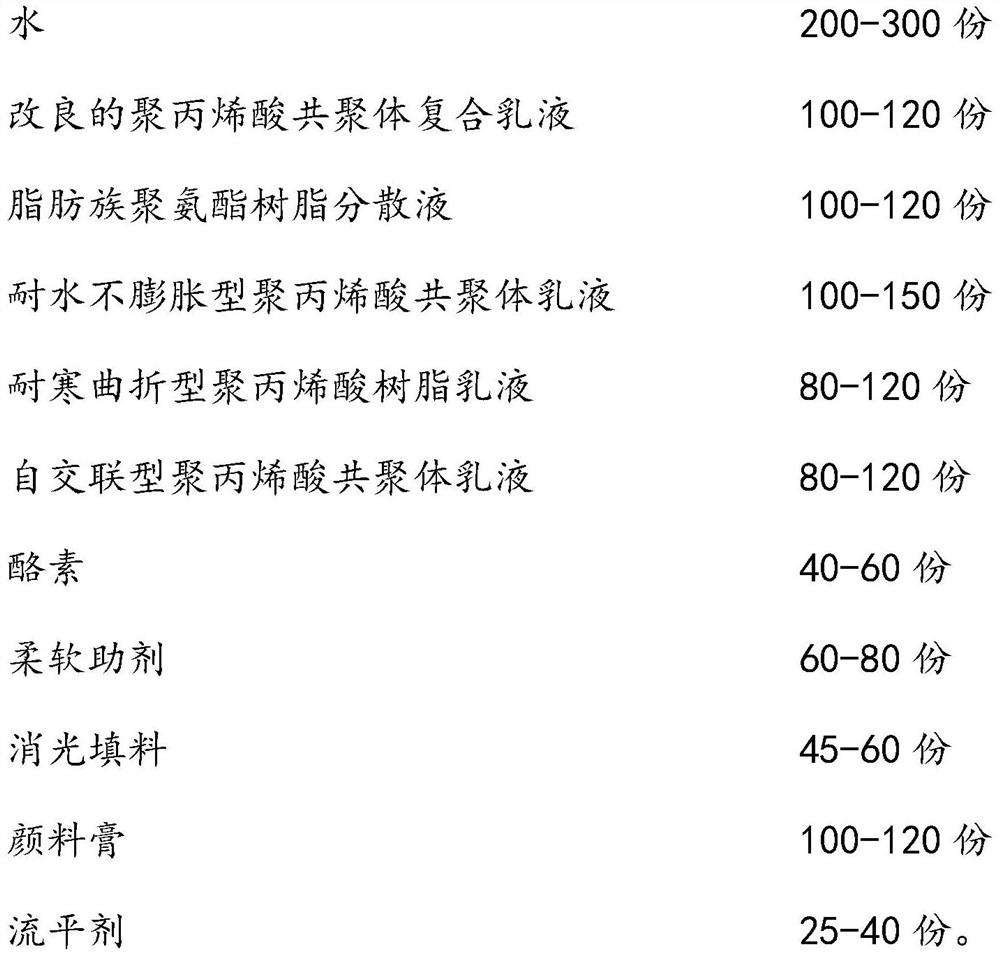

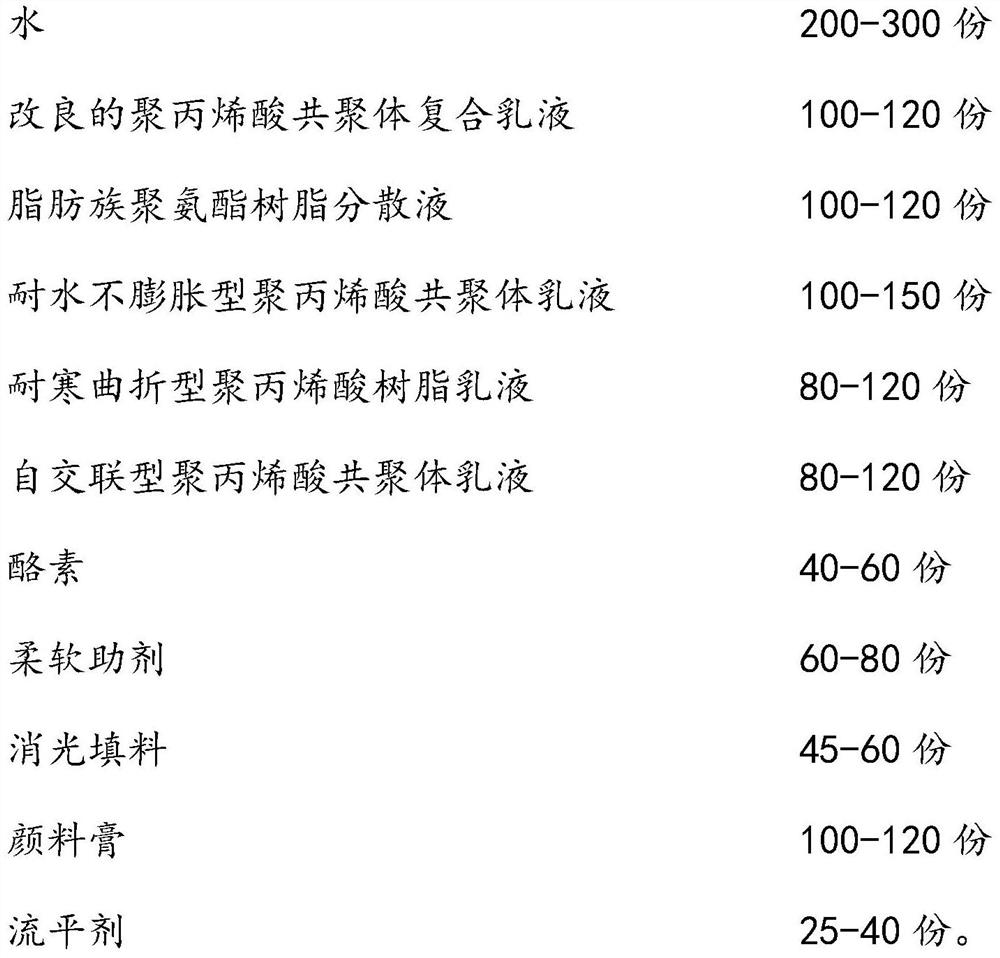

[0039] Step 2, preparation of base coat and middle coat finishing agent

[0040]200 parts by weight of water, 120 parts by weight of improved polyacrylic acid copolymer composite emulsion RC-78-555 (Staler Fine Coatings (Suzhou) Co., Ltd.), aliphatic polyurethane resin dispersion Unires RU-3904 (Staler Fine Coatings (Suzhou) Co., Ltd.) 100 parts by weight, water-resistant non-expandable polyacrylic acid copolymer emulsion RA-2 (Staler Fine Coatings (Suzhou) Co., Ltd.) 100 parts by weight, cold-resistant tortuous polyacryli...

Embodiment 2

[0048] A kind of green finishing method based on non-heavy metal tanned cow leather, comprises the steps:

[0049] Step 1. Preparation of pre-primer coating agent

[0050] 230 parts by weight of water, 85 parts by weight of aromatic polyurethane resin dispersion RODA pur EP 5 (De Rui Chemical Company), 25 parts by weight of aliphatic polyurethane resin dispersion Unires RU-3901 (Staler Fine Coatings (Suzhou) Co., Ltd.) .

[0051] Step 2, preparation of base coat and middle coat finishing agent

[0052] 250 parts by weight of water, 100 parts by weight of improved polyacrylic acid copolymer composite emulsion RC-2349 (Staler Fine Coatings (Suzhou) Co., Ltd.), aliphatic polyurethane resin dispersion Unires RU-3901 (Staler Fine Coatings (Suzhou) Co., Ltd. ) Co., Ltd.) 120 parts by weight, water-resistant and non-expandable polyacrylic acid copolymer emulsion RA-2 (Starr Fine Coatings (Suzhou) Co., Ltd.) 120 parts by weight, cold-resistant tortuous polyacrylic resin emulsion Mel...

Embodiment 3

[0060] A kind of green finishing method based on non-heavy metal tanned cow leather, comprises the steps:

[0061] Step 1. Preparation of pre-primer coating agent

[0062] 300 parts by weight of water, 90 parts by weight of aromatic polyurethane resin dispersion Astacin Ground UH TF (Basf Chemical Company), 30 parts by weight of aliphatic polyurethane resin dispersion Unires RU-3904 (Staler Fine Coatings (Suzhou) Co., Ltd.).

[0063] Step 2, preparation of base coat and middle coat finishing agent

[0064] 300 parts by weight of water, 110 parts by weight of improved polyacrylic acid copolymer composite emulsion CARE PC-5101 (Tiger Industrial Co., Ltd.), aliphatic polyurethane resin dispersion Unires RU-3910 (Starr Fine Coatings (Suzhou) Co., Ltd.) 110 parts by weight, water-resistant and non-expandable polyacrylic acid copolymer emulsion RA-2 (Starr Fine Coatings (Suzhou) Co., Ltd.) 150 parts by weight, cold-resistant tortuous polyacrylic acid resin emulsion PRIMAL SB-300 (L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com