A lamp housing cleaning device for light bulb production

A technology for the production and cleaning of light bulbs, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

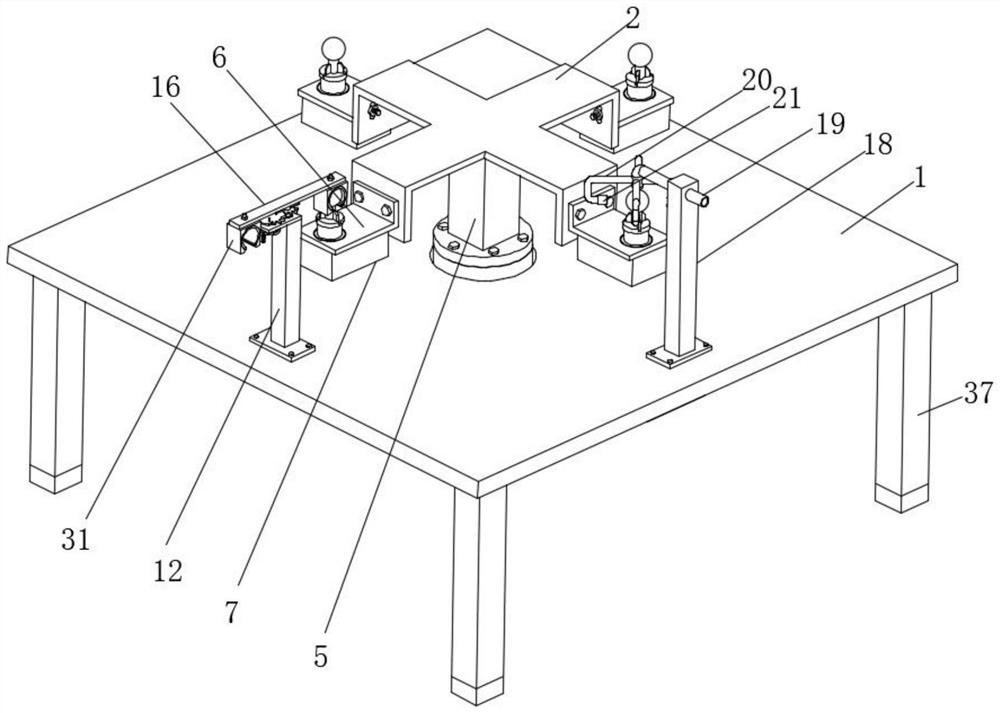

[0044] Refer to the attached Figure 1-6 , the present invention provides a lamp housing cleaning device for light bulb production, the top of the base plate 1 is provided with a mounting frame 2, the bottom of the mounting frame 2 is provided with a driving mechanism, and a clamping mechanism is installed on the mounting frame 2, so A cleaning mechanism and a wiping mechanism are arranged around the mounting frame 2;

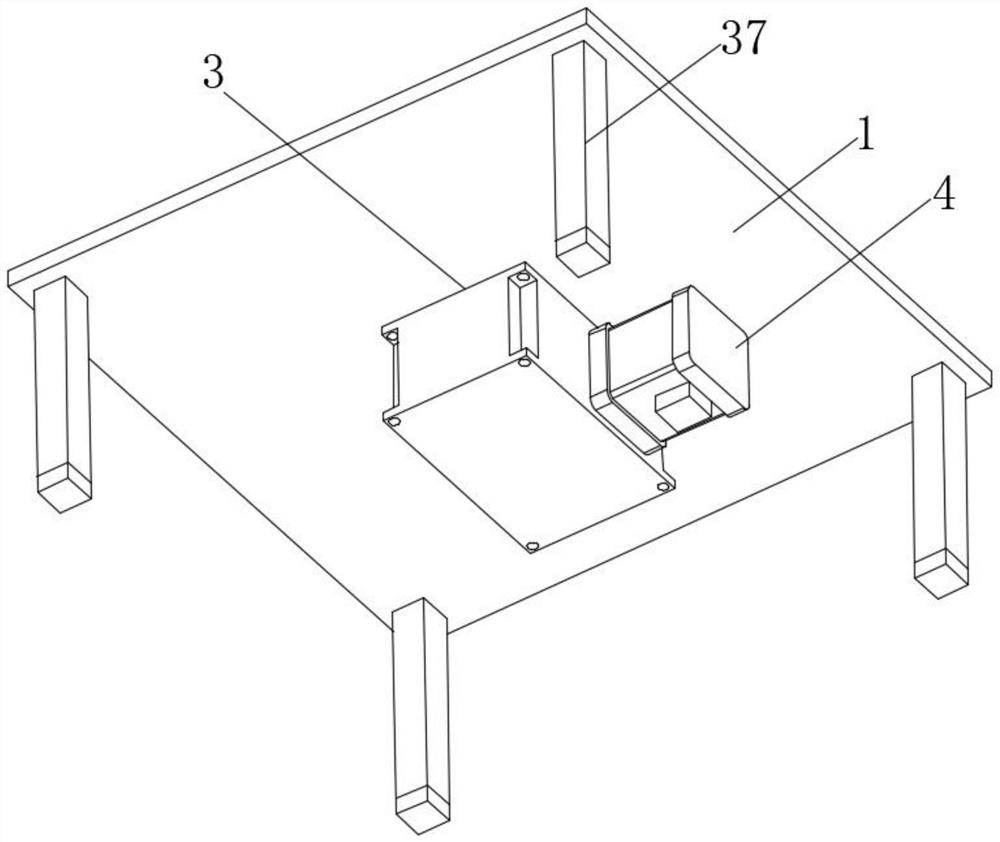

[0045] The driving mechanism includes a cam divider 3, which is fixedly connected to the bottom of the base plate 1, the input end of the cam divider 3 is fixedly connected with a first motor 4, and the output end of the cam divider 3 is fixedly connected with a first motor 4. a first column 5, the top of the first column 5 extends to the top of the base plate 1 and is fixedly connected with the mounting frame 2;

[0046] The clamping mechanism includes a mounting plate 6, the bottom of the mounting plate 6 is fixedly connected with a protective cover 7, the p...

Embodiment 2

[0059] Refer to the attached Figure 7-8 , The present invention provides a lamp housing cleaning device for light bulb production, which is different from Embodiment 1 in that the driving mechanism includes a box body 38, which is fixedly connected to the bottom of the substrate 1, and inside the box body 38 A fourth motor 39 is fixedly connected to the bottom wall, a crank 40 is fixedly connected to the output shaft of the fourth motor 39, a round pin is fixedly arranged on the top edge of the crank 40, and a sheave 41 is arranged on one side of the crank 40. The sheave 41 is matched with the crank 40 , and the center of the top of the sheave 41 is fixedly connected with a second column 42 . Actively connected, an inspection port is opened on the surface of the box body 38, an inspection door is arranged in the inspection port, and the inspection door is connected with the box body 38 through a hinge.

[0060] When in use, start the fourth motor 39, and the operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com