Hollow coil winding clamp and winding method

A technology of winding fixtures and hollow coils, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc. It can solve problems such as failure of the clamping process, machine idling, and small opening angle of the clamps, etc., to achieve the goal of clamping clamps Good tightening effect, effective pressure increase, fast and efficient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

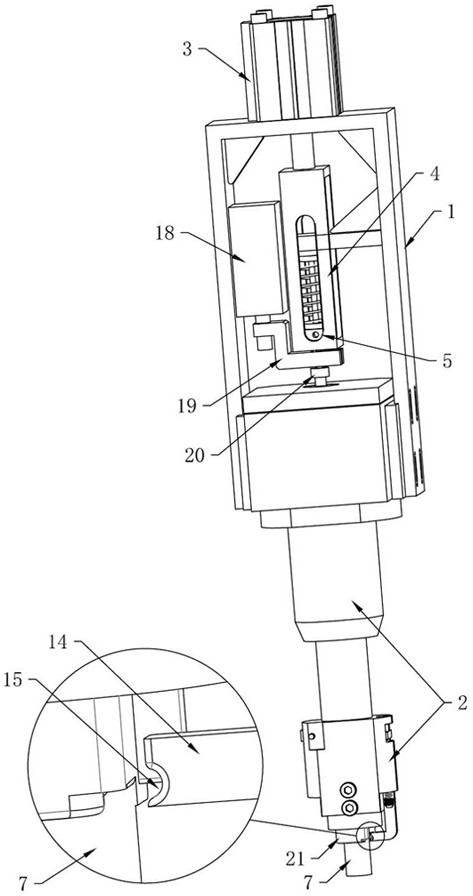

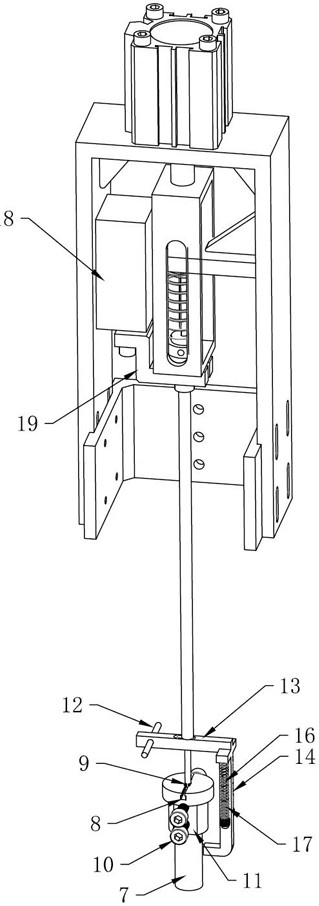

[0060] see Figure 1 to Figure 7 , The air-core coil winding jig of this embodiment includes a bracket 1, a jig head 2, a core-pulling device and a clamping device, and the air-core coil winding jig is installed on the winding machine through the bracket 1.

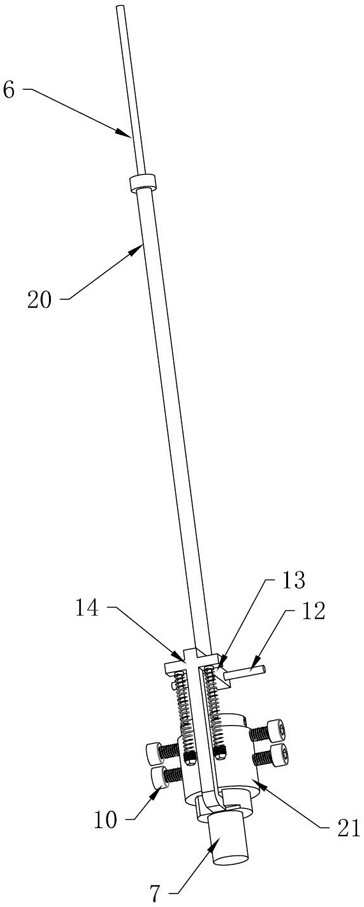

[0061] Among them, the core-pulling device includes a lifting drive device 3, a core-pulling rod 6 and a mandrel 7. The lifting drive device 3 of this embodiment can be a cylinder, an electric push rod, an electric screw, a linear motor, or other devices that can drive the core-pulling rod. 6. Lifting equipment. In this embodiment, the lifting drive device 3 is preferably a cylinder. The lifting drive device 3 is installed on the bracket 1 and drives the core-pulling rod 6 to rise or fall, and the mandrel 7 is mounted on the lower end of the core-pulling rod 6 . In order to realize fast nesting assembly, the lower end 9 of the core-pulling rod 6 is set as an I-shape, and the upper end of the mandrel 7 is provided with a ...

Embodiment 2

[0081] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the end of the core sleeve 21 close to the mandrel 7 is provided with a clamping plane 11 , and the clamping plane 11 is transitionally connected with the mandrel 7 so that the enameled wire can be smoothly wound. The wire clamping part of the cross clamp 14 is provided with a wire clamping groove 15 to better clamp the enameled wire.

Embodiment 3

[0083] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The present embodiment is also provided with a locking screw 10, and the clamp head 2 is provided with a screw hole, and one end of the locking screw 10 can pass through the screw hole of the clamp head 2 and connect with the core sleeve 21 so that the clamp head 2 and the core The sleeve 21 is locked, and the side where the core sleeve 21 connects with the locking screw 10 is set as a plane. The core sleeve 21 and the jig head 2 can be locked by the locking screw 10 to prevent the core sleeve 21 and the jig head 2 from rotating relative to each other and sliding up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com