A balanced design method for multi-person co-station incomplete dismantling line for processing mixed waste products

A product, co-station technology, applied in the field of multi-person co-station in the field of incomplete dismantling line balance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

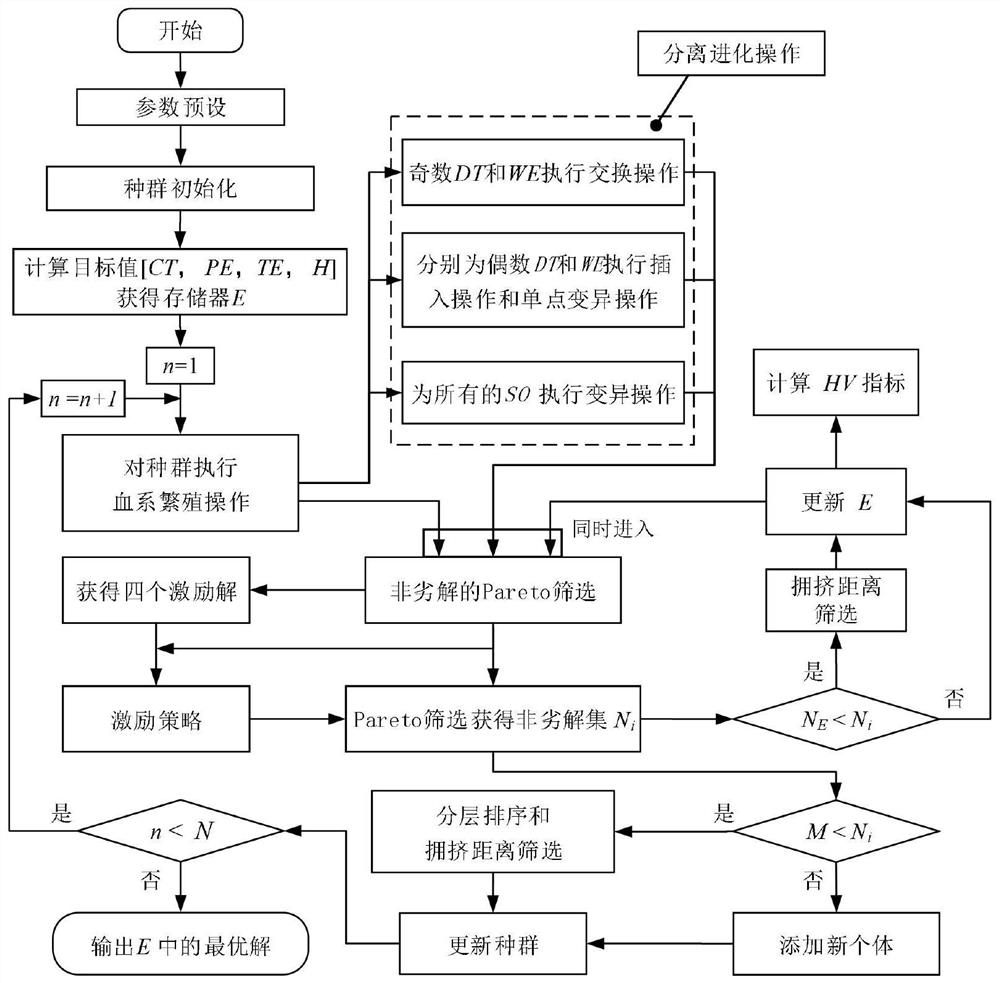

[0034] A balance design method of incomplete dismantling line for multi-person co-station for processing mixed waste products, comprising the following steps:

[0035] S1. A mathematical model is established with the goal of minimum workstation takt time, disassembly cost, demand index, and hazard index. The objective function of the mathematical model is as follows:

[0036] min CT (1)

[0037]

[0038]

[0039]

[0040] Among them, U is the total task set of all products, i, j is the task number, i, j∈U; s is the workstation number s∈S; w is the worker number, w∈W; is the start time of dismantling task i, if i is the first task in the hands of workers in workstation s, then t iw is the dismantling processing time for worker w to perform task i after considering the recycling status of product parts and worker skill differences; dc i is the disassembly cost per unit time to perform task i; oc s running cost per unit time for workstation s; hp w is the hourly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com