Non-contact acoustic emission detection method for safety state of fire scene building structure

A technology of acoustic emission detection and building structure, which is applied in the testing of machines/structural components, material analysis and measurement devices using acoustic emission technology, which can solve the problem of inability to make judgments in the development stage of a fire and difficulty in satisfying fire scene mobility. , high stability, multiple hardware devices, etc., to achieve multiple emergency response and escape time, rich early warning functions, and convenient and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

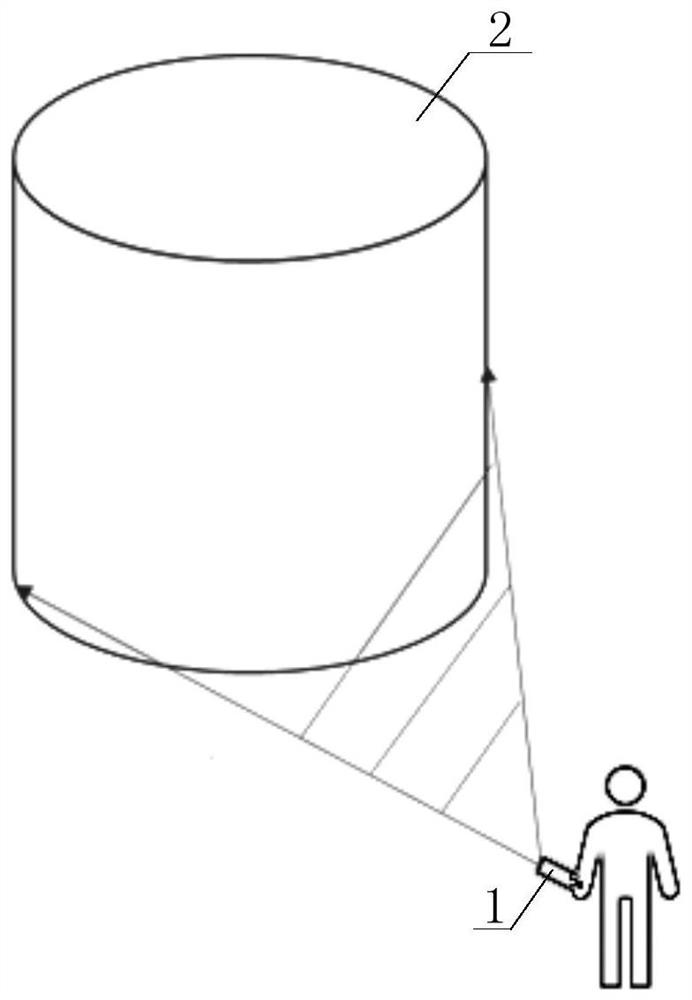

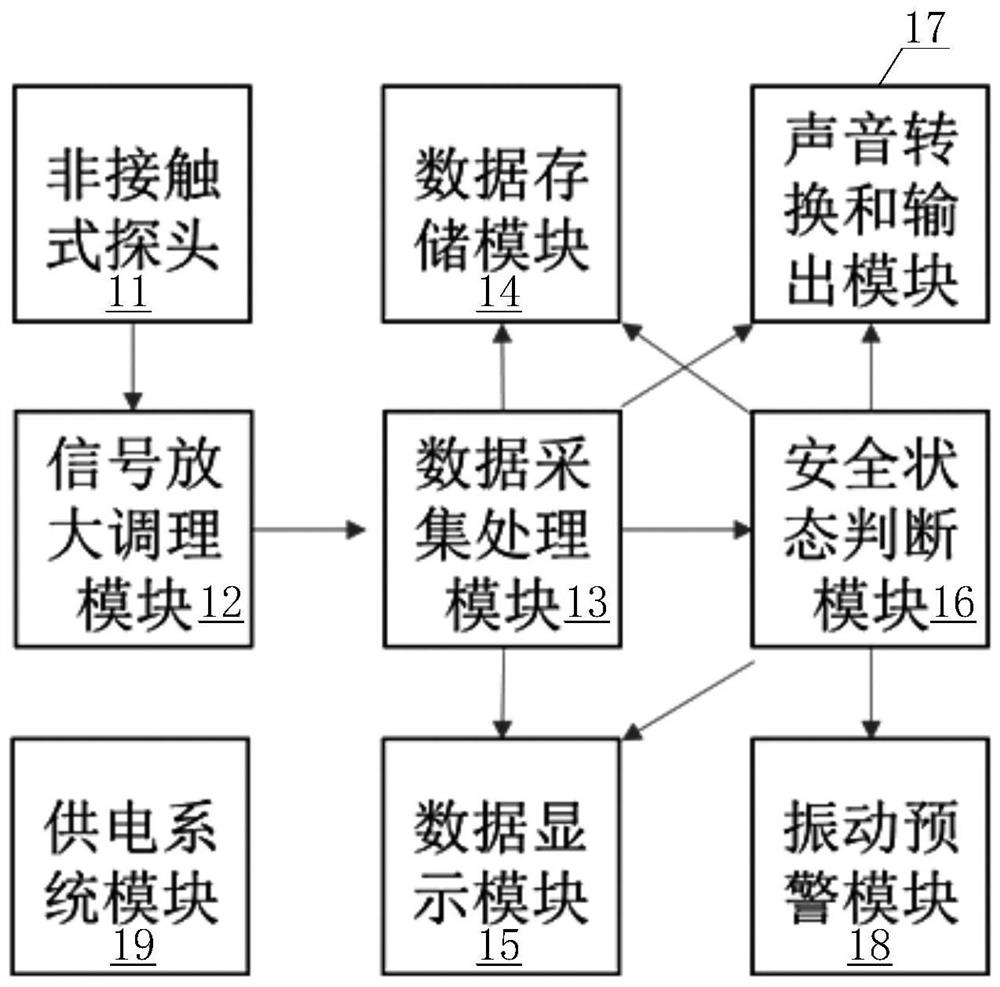

[0032] Below according to the accompanying drawings figure 1 and figure 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0033] see figure 1 and figure 2 , a non-contact acoustic emission detection method for the safe state of a building structure in a fire scene according to an embodiment of the present invention. The operator holds the acoustic emission detector 1 provided by the present invention and places it at a distance L (0<L<10m) from the building structure 2 Align the non-contact probe 11 at the front end of the acoustic emission detector 1 with the building structure 2 to receive the acoustic emission signal from the building structure 2 transmitted through the air. Continuously moving the acoustic emission detector 1 and aiming at different positions of the building structure 2 can complete the scanning detection. Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com