Online particle depolymerization system based on aerosol agglomeration principle

An aerosol and agglomerated particle technology, applied in the field of online particle depolymerization system, can solve the problems of eliminating heat and mass transfer performance changes, and achieve stable dispersion effect and stable feedback adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

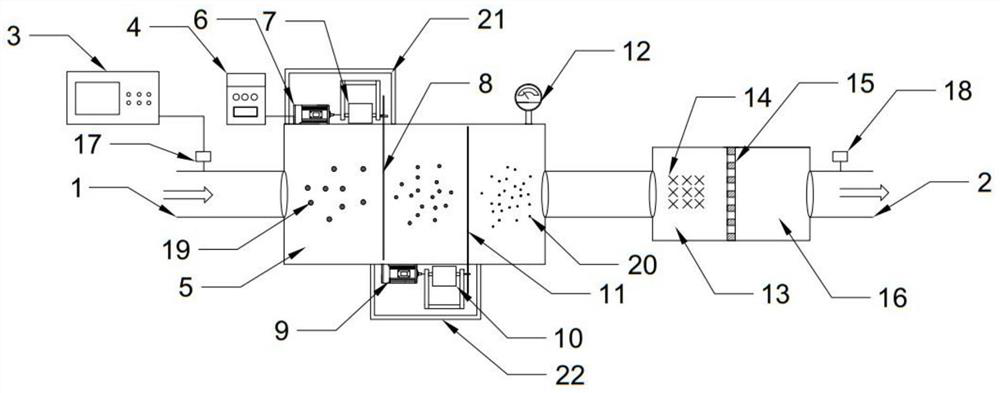

[0030] Such as figure 1 As shown, this embodiment relates to an online particle deaggregation system based on the principle of aerosol agglomeration, including: a two-stage vibration dispersion module connected in sequence, an electrostatic neutralization module and a measurement and control system connected to it respectively, wherein: The agglomerated particles 19 in the gas pipeline 1 are dispersed by two-stage vibration and then electrostatically neutralized to form an aerosol with a particle size ranging from 1 μm to 200 μm.

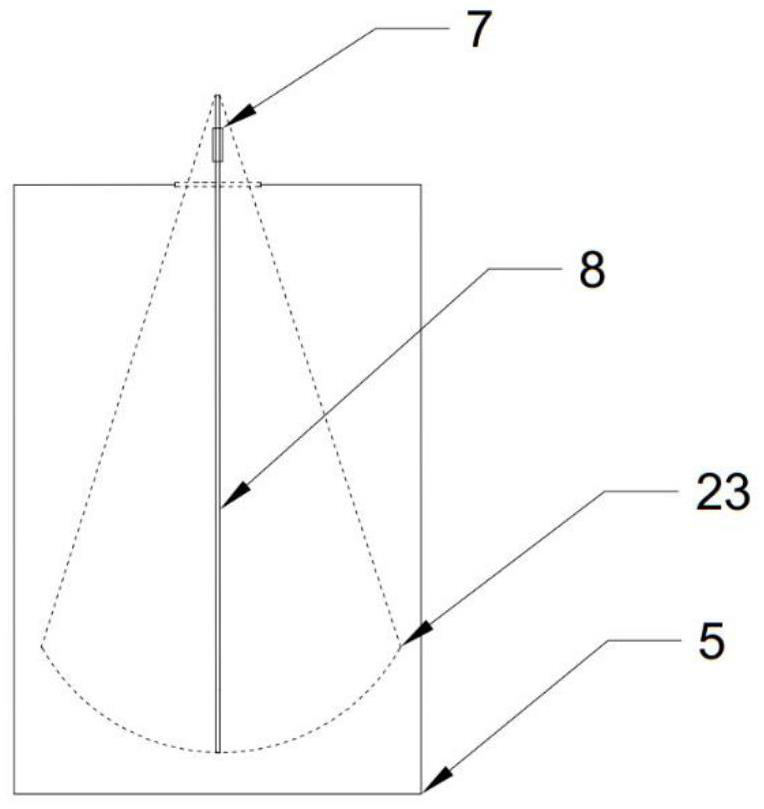

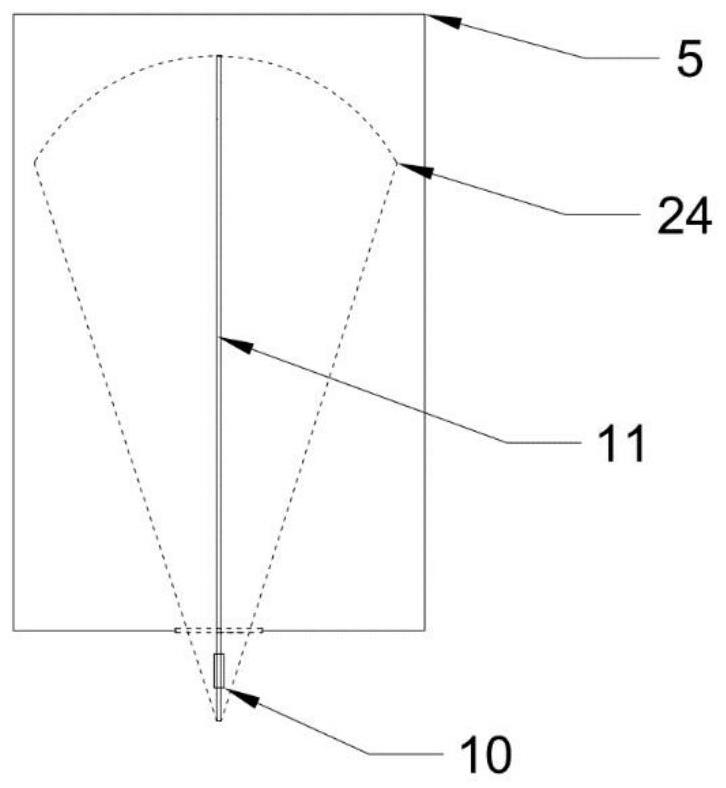

[0031] Such as Figure 1 ~ Figure 3 As shown, each level of vibration dispersion module includes: vibration dispersion chamber 5, first level motor 6, first level vibrator 7, first level vibration probe 8, wherein: first level motor 6 and first level The vibrator 7 is located above the vibration dispersion chamber 5, the first-stage vibrator 7 controls the vibration of the first-stage vibrating probe 8 through the connection assembly, and the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com