Method for calculating carbonization depth of concrete beam

A technology of carbonization depth and concrete beams, applied in the direction of strength characteristics, test material hardness, measuring devices, etc., can solve the problems of micro-cracks and pore fatigue growth in concrete, accelerate carbonation of reinforced concrete beams, etc., and improve effectiveness and accuracy , improve the accuracy, and the effect of parameter calculation is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] A method for calculating the carbonation depth of a concrete beam, comprising the steps of:

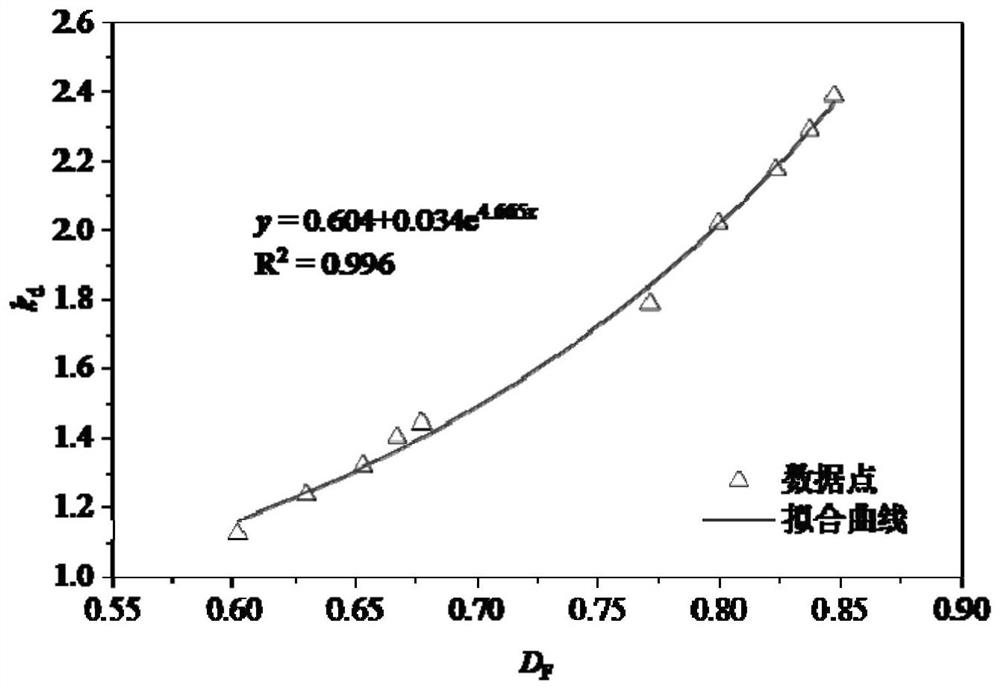

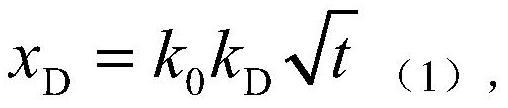

[0040] S1. Collect the carbonation depth and carbonation time data of the concrete beam under the coupled action of repeated load and carbonation erosion, and fit the square root of the carbonation depth and carbonation time to obtain the carbonation depth formula:

[0041]

[0042] where x D is the carbonation depth of fatigue damaged concrete, in mm; k 0 is the carbonation coefficient of undamaged concrete; k D is the influence coefficient of fatigue damage, t is the carbonization time, and the unit is d;

[0043]S2. Collect the carbonation depth and carbonation time data of the unfatigue-damaged concrete beams subjected to carbonation erosion at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com