Device and method for measuring mercury in flue gas based on low-temperature plasma pyrolysis

A low-temperature plasma and plasma technology, applied in the direction of measuring devices, separation methods, sampling devices, etc., can solve the problems of lack of measurement of particulate mercury, difficult conversion, interference, etc., and achieve simple and accurate mercury concentration , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with embodiment.

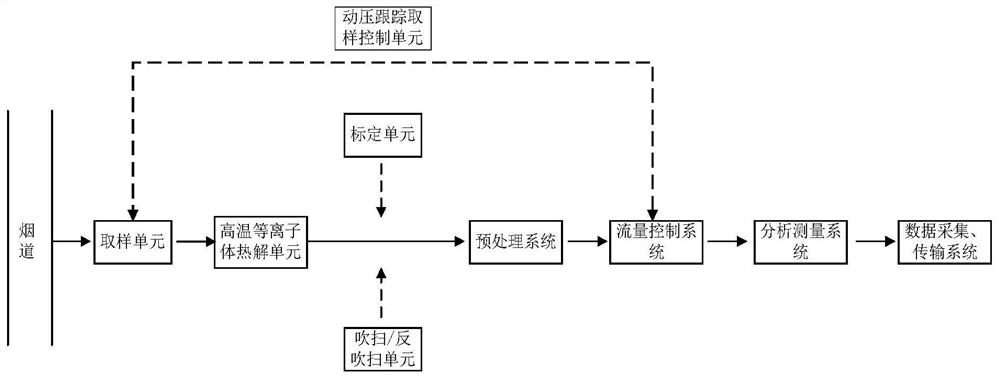

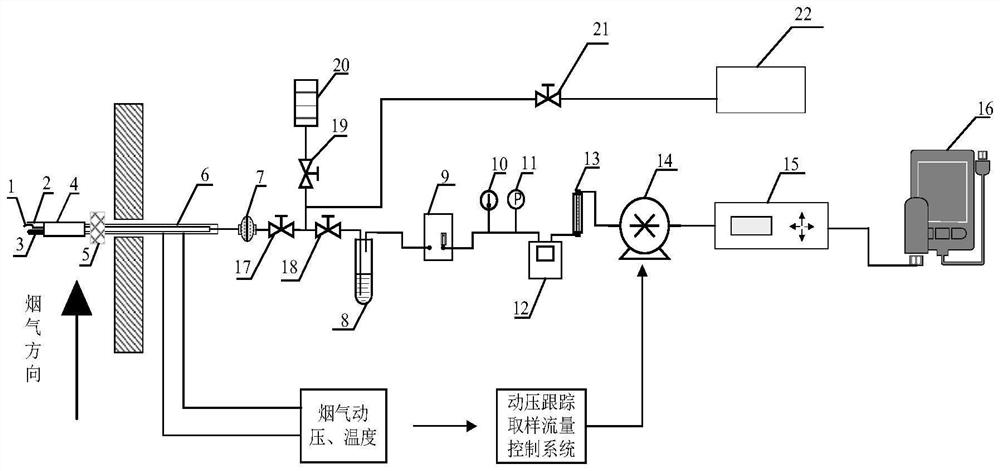

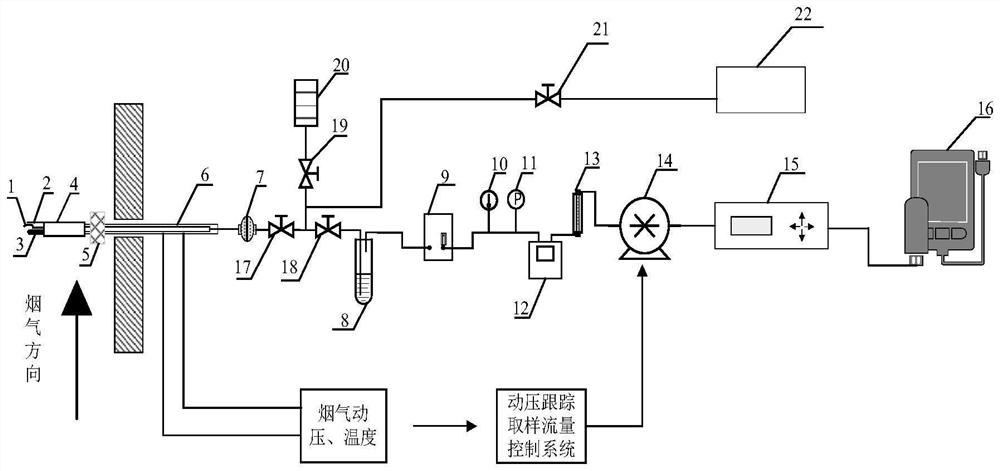

[0037] Such as figure 1 , figure 2 Shown: Mercury in flue gas is divided into three forms: elemental mercury Hg 0 , Oxidized mercury Hg 2+ and particulate mercury Hg p , the existing mercury online testing system can only directly test elemental mercury, while oxidized mercury must be reduced to elemental mercury through a conversion system before it can be monitored. The current online detection system needs to filter the smoke and then detect the elemental mercury in the flue gas, but cannot measure the particulate mercury, and the oxidized mercury in the flue gas must be converted into elemental mercury for measurement. At present, the conversion methods of oxidized mercury are mainly chemical method and pyrolysis method. The chemical method uses reducing chemical reagents such as SnCl 2 Or the photocatalytic method, and the pyrolysis method is to convert the oxidized m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com