Semi-fabricated concrete guardrail and mounting method thereof

A concrete and semi-assembled technology, applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problems of low production efficiency, low strength, prone to corrosion, cracking, etc., saving construction time and labor, and increasing the use of Longevity, water loss prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

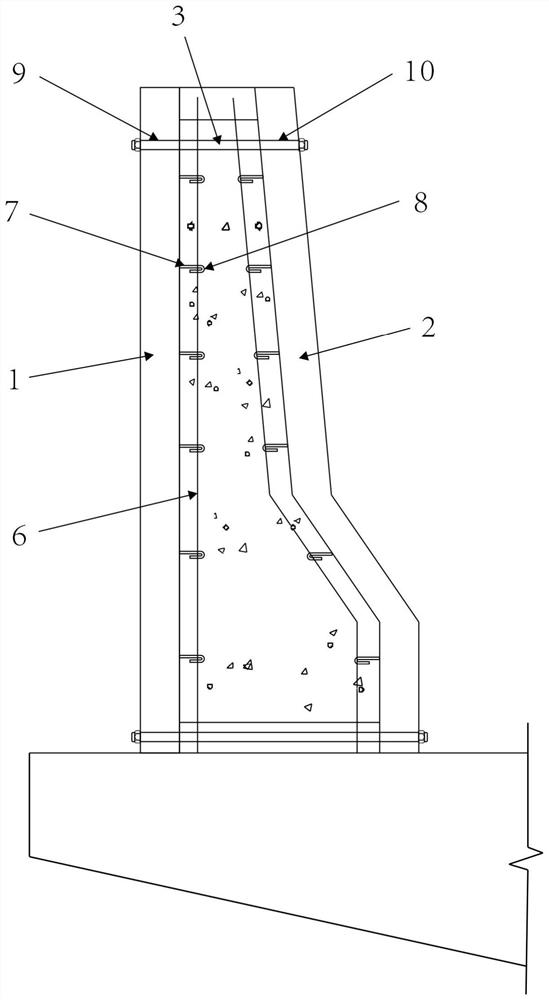

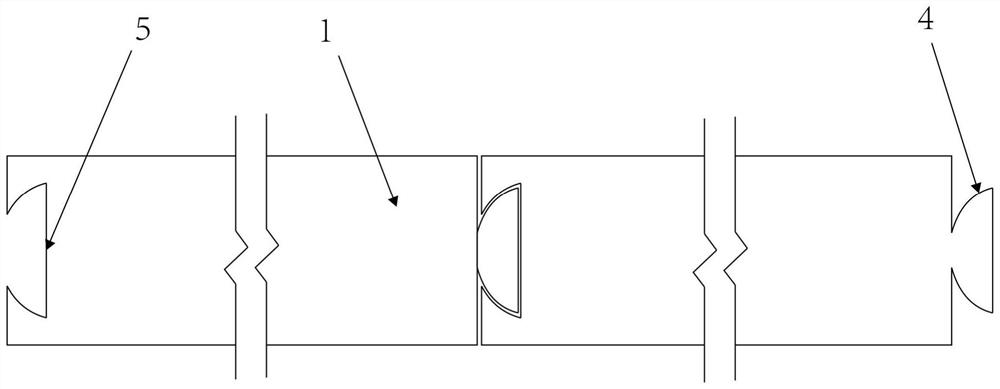

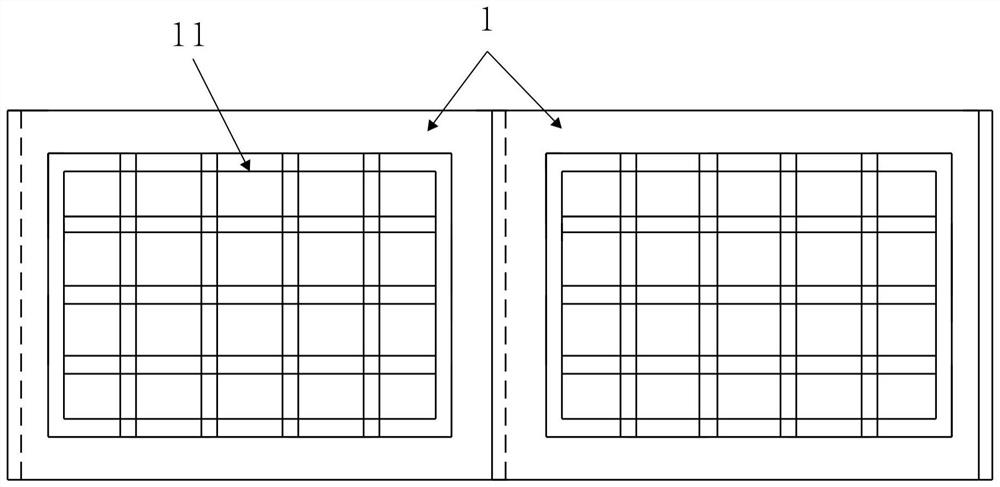

[0034] Among them, 1. The first sub-side panel, 2. The second sub-side panel, 3. Pull bolts, 4. Protruding ears, 5. Card slots, 6. Reinforcement cages, 7. Anchor bars, 8. Curved hooks, 9, the first bolt hole, 10, the second bolt hole, 11, the stiffener.

[0035] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

[0036] like figure 1 As shown, the semi-fabricated concrete guardrail of this scheme includes the first side plate and the second side plate poured from high-performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com