Paving structure of electric vehicle track in level crossing transition area and construction method of the paving structure

A technology for tram tracks and level crossings. It is applied to the upper structure of the track, the track, and the cohesive pavement paved on site. It can solve the problems of poor road quality, impact load, and dynamic deformation of the road surface, and achieve excellent flexibility and fatigue performance. , prevent water damage and corrosion, the effect of non-slip wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

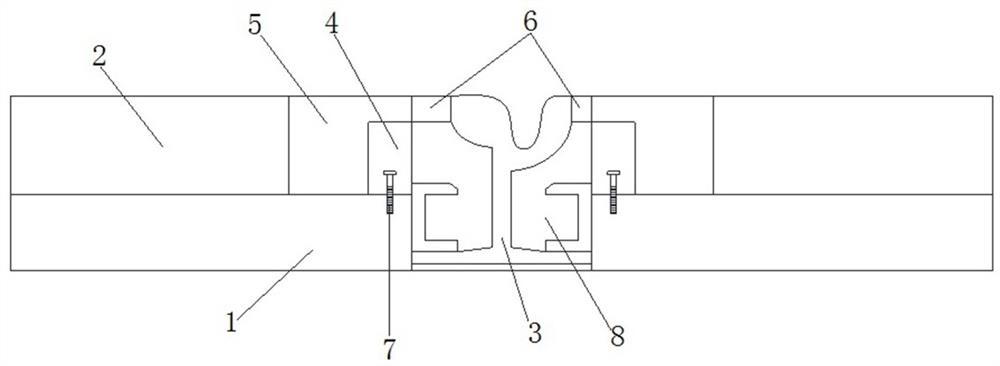

[0035] Example: such as figure 1 As shown, the tram track structure in the level crossing transition area in this embodiment includes a concrete layer 1 as the base layer and an asphalt surface layer 2 as the pavement layer, wherein the asphalt surface layer 2 is laid on the top of the concrete layer 1 . By selecting the high-strength concrete layer 1 as the road base, the strength, stability and durability of the road can be effectively guaranteed, and the asphalt surface layer 2 can be used as the road surface layer to ensure the smoothness of the road surface and improve driving comfort.

[0036] like figure 1 As shown, a through groove is opened at the same position of the concrete layer 1 and the asphalt surface layer 2, that is, the design position of the steel rail, and the through groove penetrates the concrete layer 1 and the asphalt surface layer 2 . A steel rail 3 is installed in the through groove, and both sides of the steel rail 3 have sleepers 8, so that the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com