Screwing type press-fitting machine

A press-fitting machine and screw-on technology, which is applied in the field of press-fitting machines, can solve the problem of inability to replace the press-fitting head, etc., and achieve the effect of preventing damage and ensuring work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

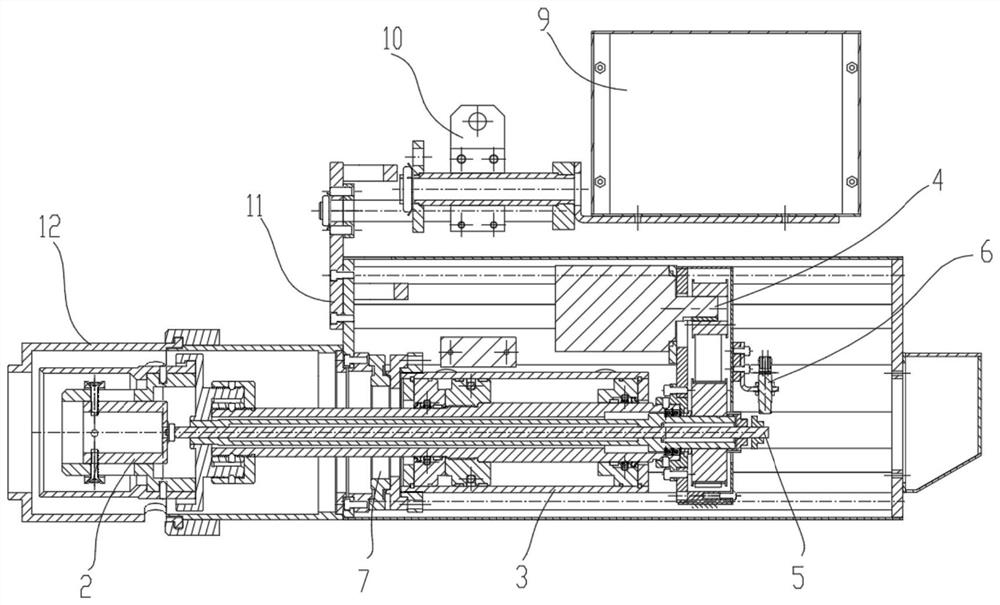

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

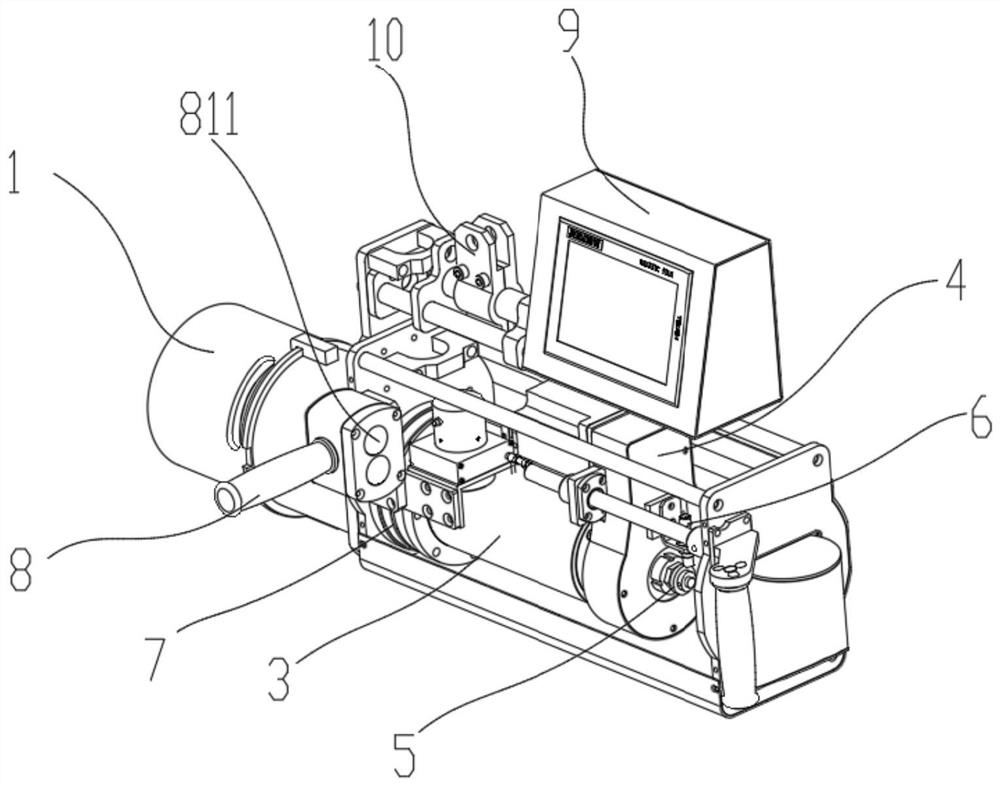

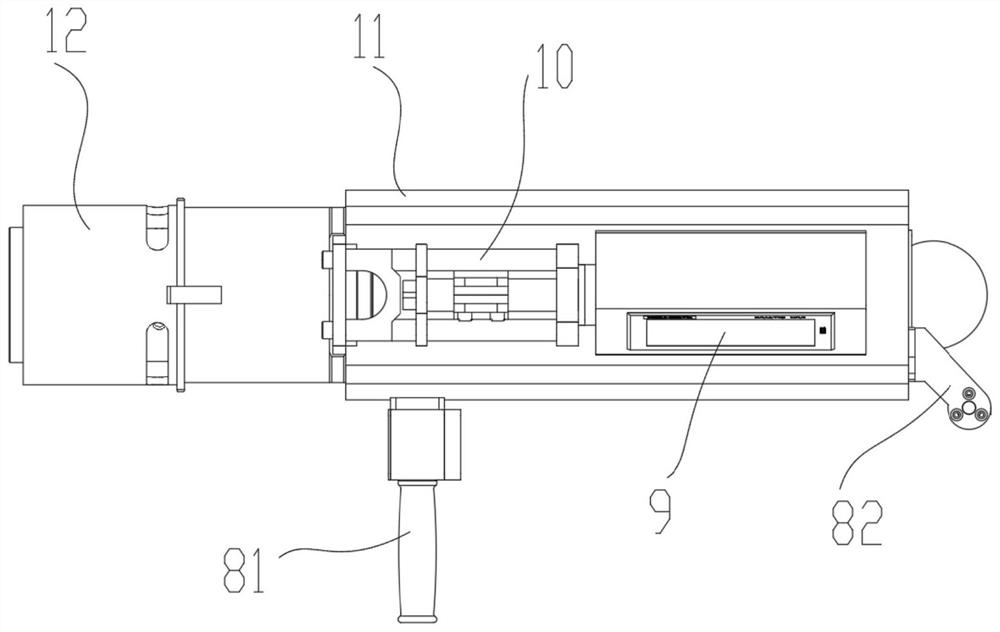

[0028] refer to figure 1 and figure 2 , The invention provides a screw-in press-fitting machine, which solves the technical problem that the press-fitting machine in the prior art cannot replace the press-fitting head.

[0029] In order to achieve the above technical purpose, the technical solution of the present invention provides a screw-in press-fitting machine, which is used for press-fitting interference-fit parts such as bearings or seat rings sleeved on the workpiece, which includes a press-fitting mechanism 1 and a fixing mechanism 2 and a driving member 3, the fixing mechanism 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com