Ceramic body raw material processing device and processing process thereof

A technology for processing raw materials and ceramic bodies, which is applied in the field of raw material processing devices for ceramic bodies and its processing technology, and can solve problems such as product quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

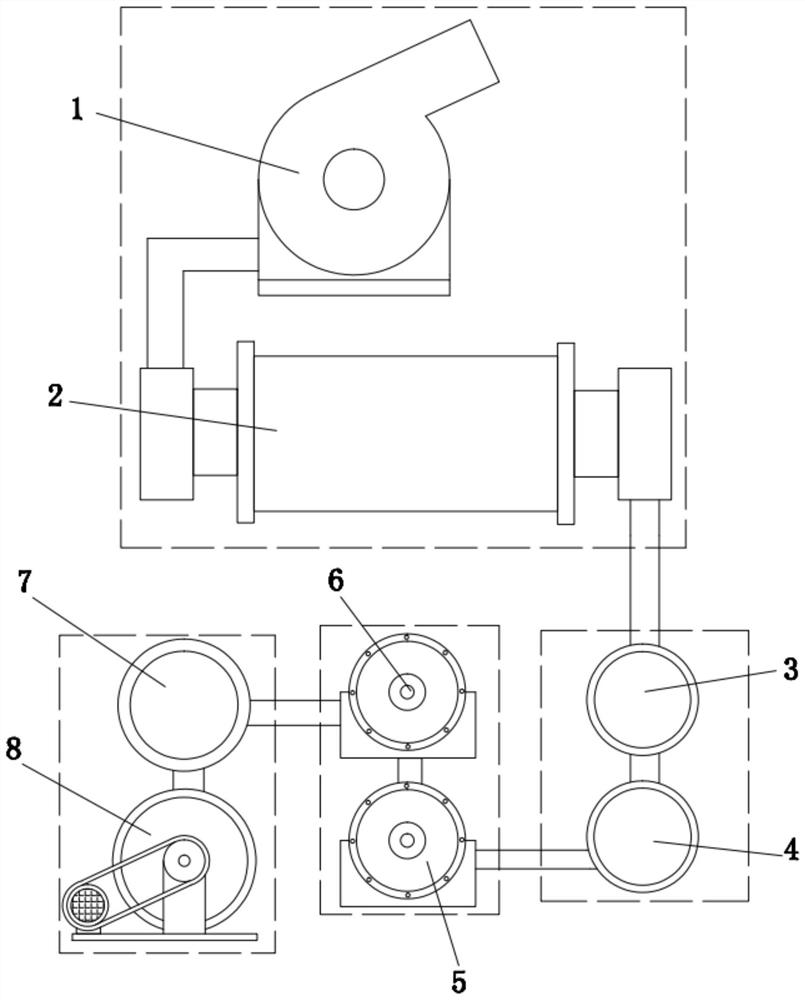

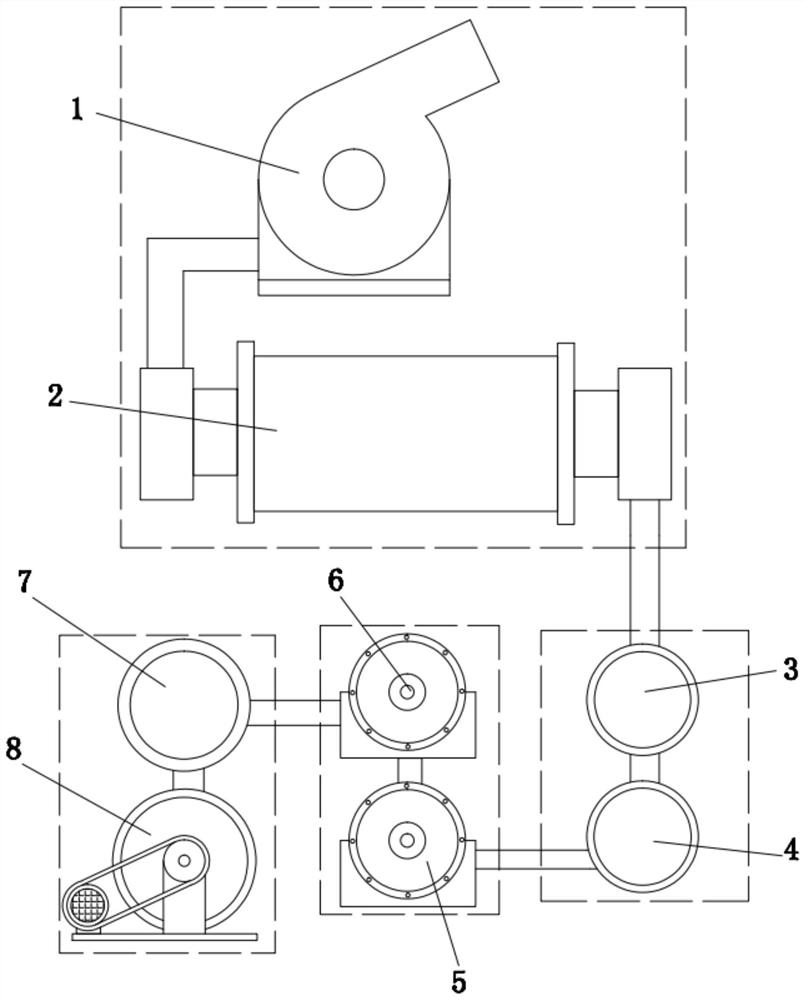

[0027] refer to figure 1 , a ceramic body raw material processing device and its processing technology, including a crushing and refining module, the crushing and refining module includes a crusher 1 and a ball mill 2, and the discharge port of the crusher 1 passes through the feeding device and the feed port of the ball mill 2 connected. The crushing and refining module is connected with the sedimentation module through the feeding device, and the sedimentation module is connected with the magnetic separation module through the feeding device. The underground slurry tank 3 is connected, and the underground slurry tank 3 is connected with the above ground slurry tank 4 through a feeding device. The magnetic separation module is connected with the dehydration module through the conveying device. The dehydration module includes a mud transfer tank 7 and a vacuum dehydrator 8. The magnetic separation module communicates with the mud transfer tank 7 through a feeding device, and...

Embodiment 2

[0029] refer to figure 1 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the magnetic separation module includes a first-stage magnetic separator 5 and a second-stage magnetic separator 6, and the sedimentation module is connected with the first-stage magnetic separator through a feeding device. The feed port of the separator 5 is connected, and the discharge port of the first-stage magnetic separator 5 is connected with the feed port of the second-stage magnetic separator 6 through a feeding device. Both magnetic separators are vertical magnetic separators, mainly composed of high-pressure water washing device, frame, excitation coil, iron yoke, magnetic medium, high-pressure air washing device, heat exchanger (optional), etc. The working principle of the vertical magnetic separator is as follows: during ore dressing, the excitation line is connected with direct current to generate an induced magnetic field in the separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com