Efficient combustion-supporting household garbage treatment equipment and household garbage treatment method thereof

A technology for domestic waste and treatment equipment, applied in the field of grate furnace, can solve the problem of low combustion-supporting effect, and achieve the effect of high-efficiency incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

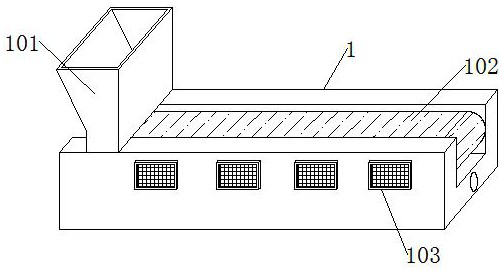

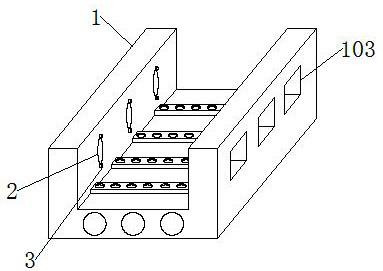

[0033] Please refer to Figure 1 to Figure 7 middle:

[0034] A high-efficiency combustion-supporting domestic waste treatment equipment, comprising: a main body 1, a coal hopper 101 is connected above the main body 1, a chain grate 102 is arranged in the middle of the main body 1, and vents 103 are connected on both sides of the main body 1, and the vents 103 pass through slots The fitting groove 1031 on one side is connected with the suction shaft 2 that can be displaced left and right. The suction shaft 2 fits and penetrates through the through shaft 2021 on the side of the counter plate 202 through the middle piston plate 203. The upper and lower ends of the vent 103 are offset The protruding part of the chute 1033 is connected with the transmission shaft 3, and the piston disc 203 is connected with the rotating telescopic rod 2031 through one side of the thread and is connected with the blocking plate 2032. 2032 is fitted and connected together through the limiting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com