Method for coating pipeline and pipeline

A pipeline and coating technology, applied in the direction of pipes/pipe joints/pipe fittings, devices for coating liquid on the surface, coatings, etc., can solve problems such as expensive and complicated measures, achieve accurate implementation, cost-effective, and eliminate complexity The effect of the measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

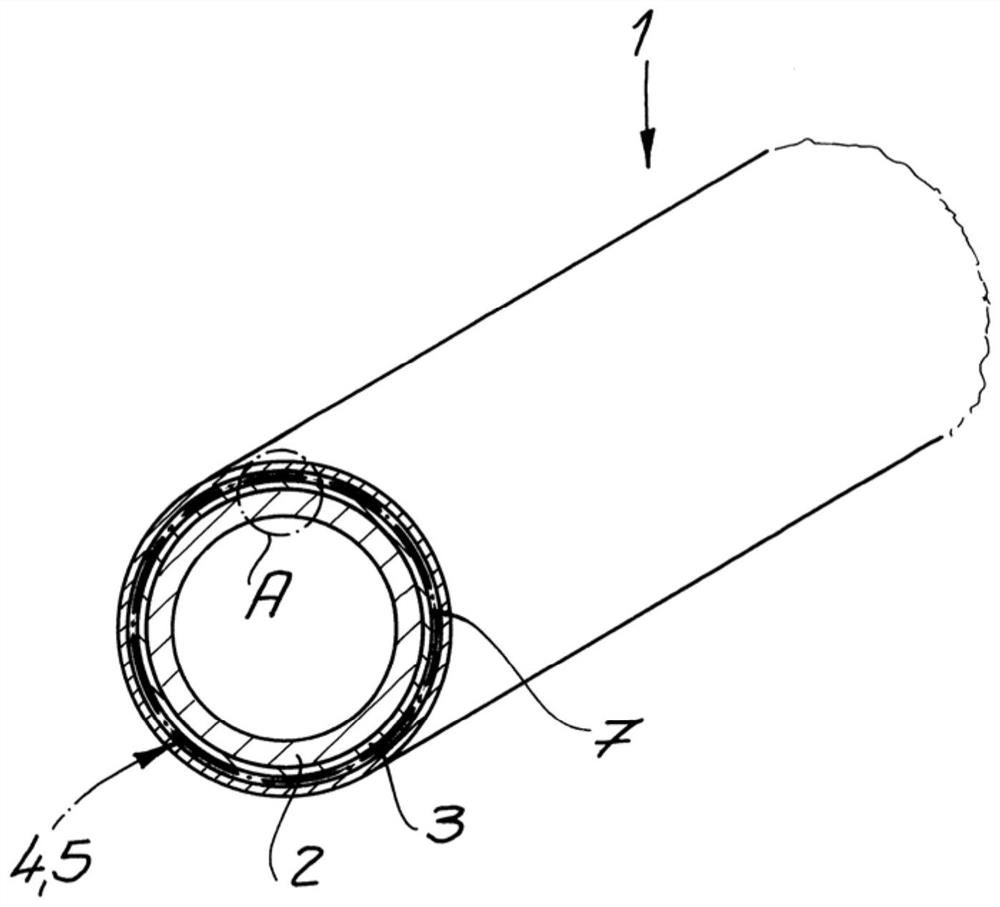

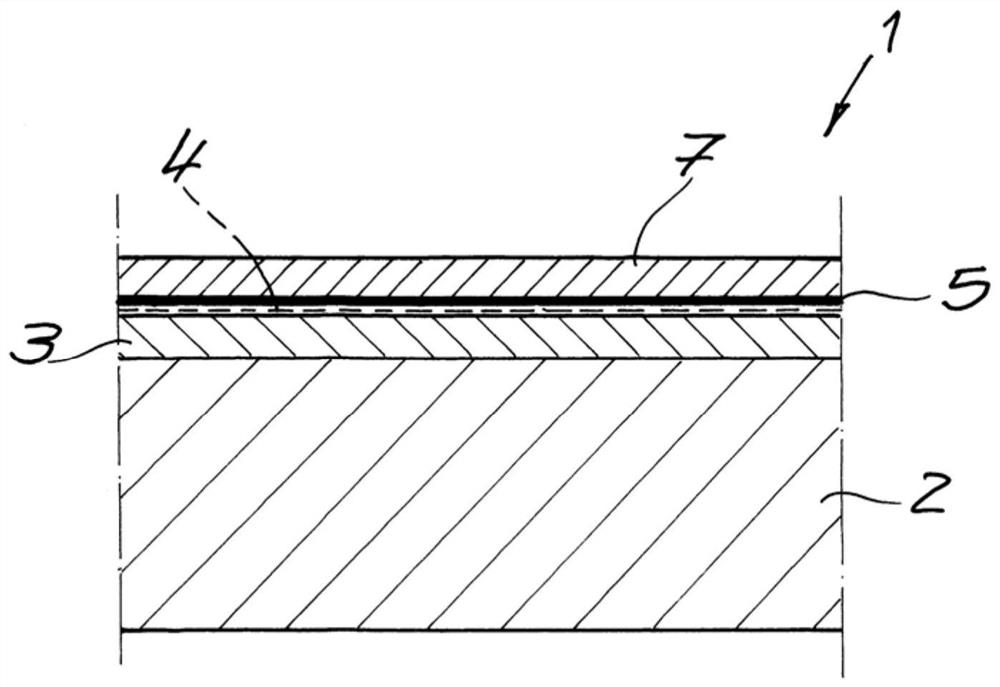

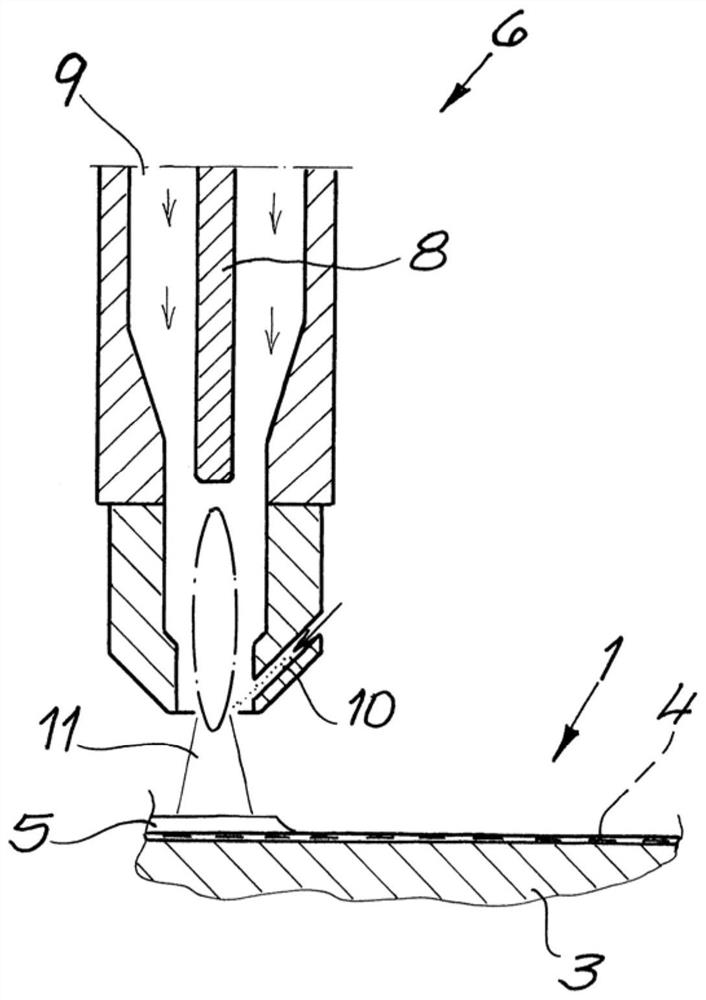

[0020] The figures show a pipe 1 coated based on the method according to the invention. In an exemplary embodiment, it may preferably be a motor vehicle conduit, preferably a conduit for fuel and / or hydraulic fluid. The pipe 1 has a metal inner tube 2 which is preferably designed as a steel pipe in the exemplary embodiment. The metal inner tube 2 is provided with a metal layer 3 , which is preferably designed as an aluminum layer in the exemplary embodiment. This aluminum layer can be applied to the metal inner tube 2 by hot dipping. In particular, a metal layer 3 made of Galfan can be applied to the metal inner tube 2 instead of an aluminum layer.

[0021] In a preferred embodiment and in an exemplary embodiment, the chrome-free intermediate layer 4 is applied to the metal layer 3 or to the aluminum layer and may in one embodiment have a phosphating agent.

[0022] In an exemplary embodiment, the layer thickness of the metal layer 3 may have a dimension of 50 μm to 150 μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com