Sterilization production method of packaged water suitable for safe drinking of mothers and infants

A production method and safe technology, applied in packaging, transportation, packaging, application, etc., can solve the problems of not being able to ensure that the bottle mouth is not exposed, adding, etc., and achieve the effect of ingenious design, convenient use, and guaranteed aseptic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

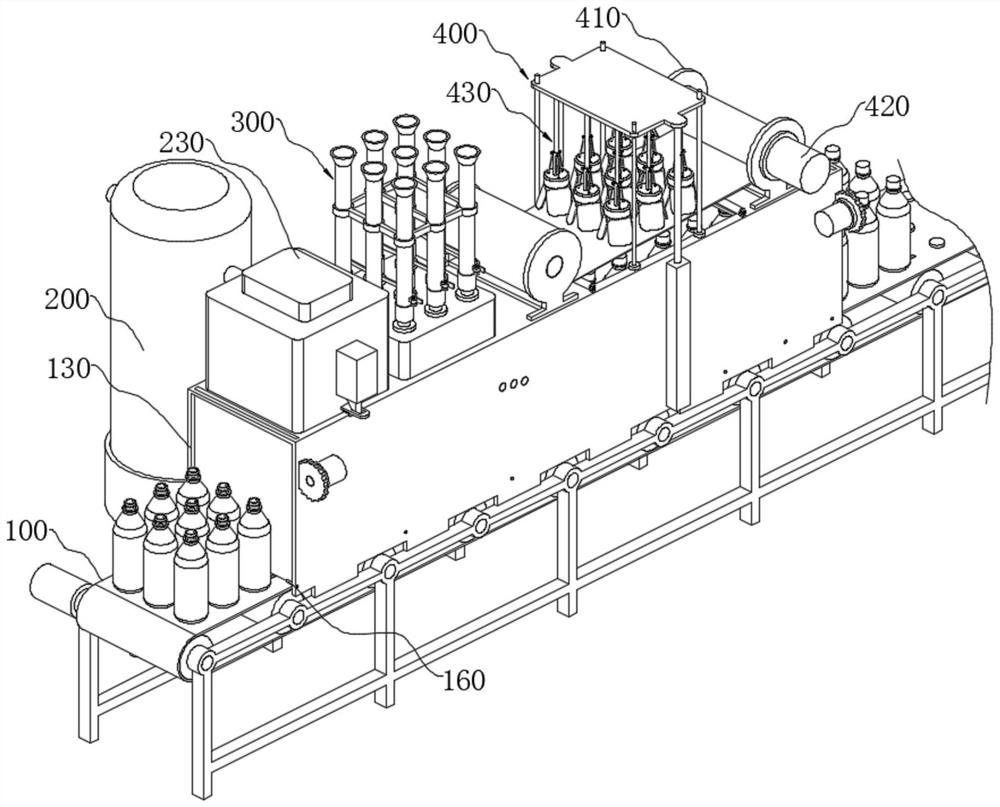

[0060] see Figure 1-Figure 15 As shown, the present invention provides a kind of packaging water sterilization production method suitable for mother and infant safe drinking, comprising the following steps:

[0061] 1. Water purification injection stage:

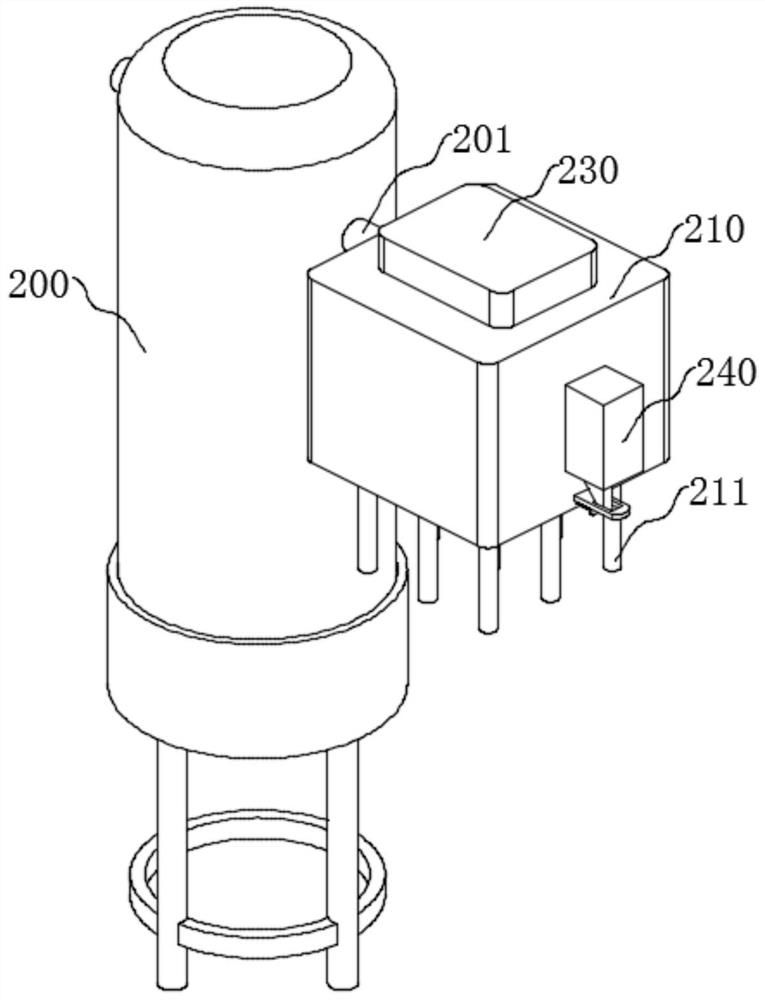

[0062] S1. First inject clean water into the water injection tower 200 of the packaging water sterilization equipment, and when it is full, it will overflow into the overflow tank 210, and then start the pulse light 230 to continue the sterilization;

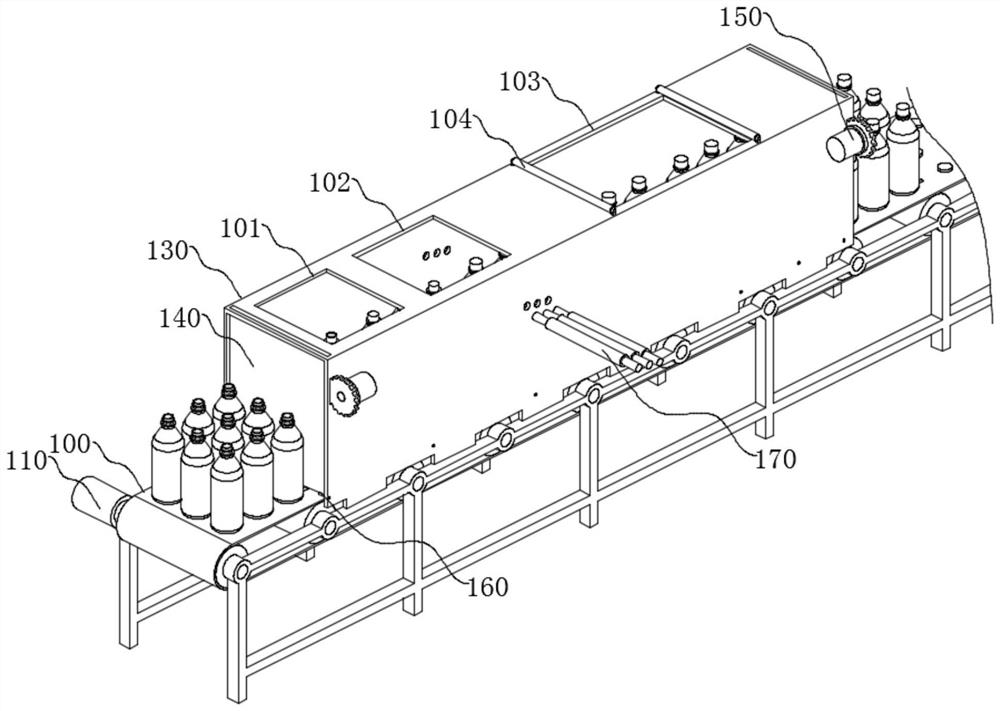

[0063] S2, then start the conveying servo motor 110 to drive the conveyor belt 100 to move forward by a fixed stroke, and convey a number of packaging bottles directly below the overflow tank 210;

[0064] When a number of packaging bottles are transported to the beginning of the antibacterial cover 130, the metal sheet 121 in front of it will be sensed by the first start proximity switch 160, which will trigger the door curtain servo motor 150 to start, and then drive the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com