Cable terminal protection terminal and production process thereof

A cable terminal and terminal technology, which is applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problems of easy-to-break terminal and cable protection, protection terminal and insulating sheath are easy to enter water, and connection reliability is reduced. Easy to make, good airtightness, and the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

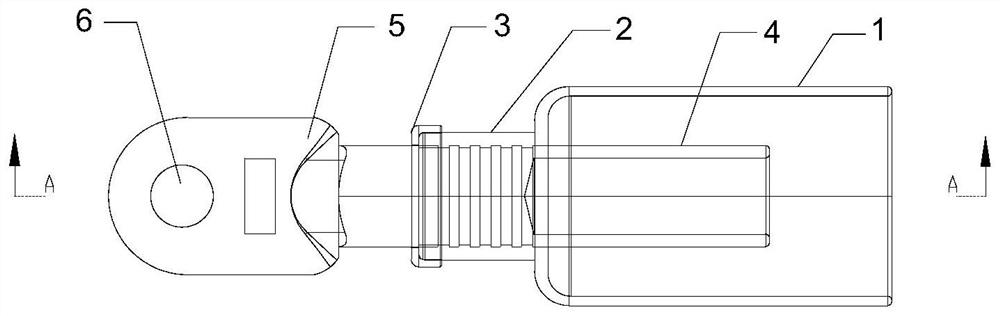

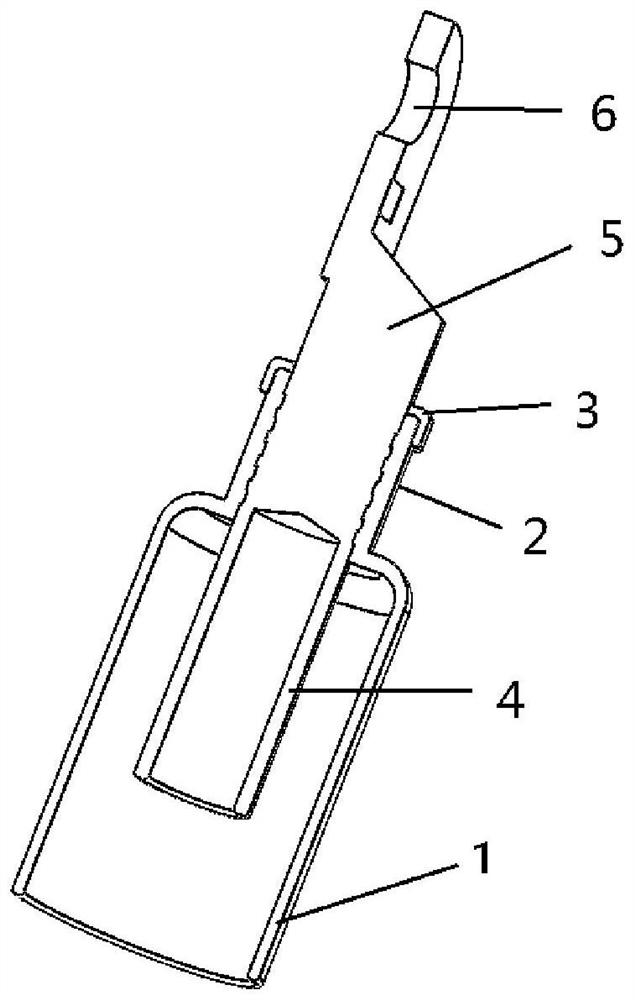

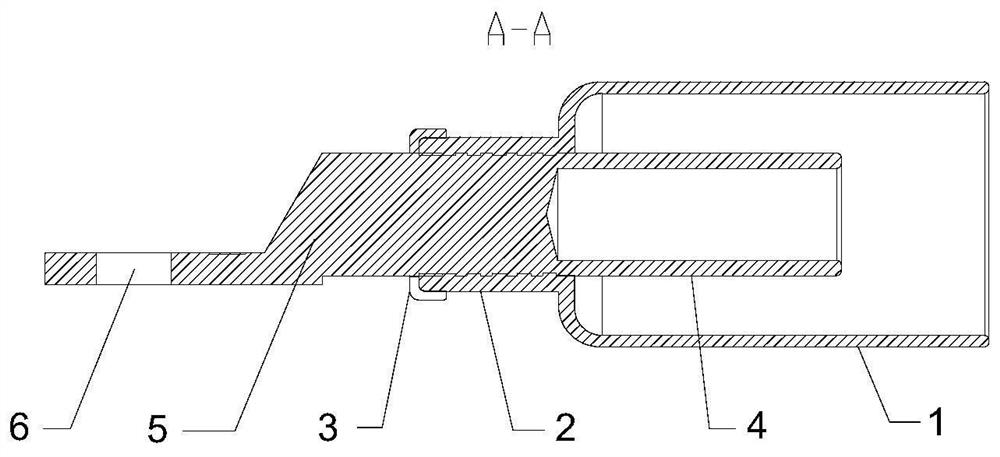

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0031] Such as Figure 1-3 As shown, the cable terminal protective terminal is characterized in that it includes a terminal head 5, a terminal rod 4, a protective cover 1, and a connecting cover 2; wherein the terminal head 5 is arranged at one end of the terminal rod 4, and the other end of the terminal rod 4 is The hollow structure is used to fix the cable; the terminal rod 4 is provided with a metal waterproof cap 3, the opening of the metal waterproof cap 3 faces the fixed end of the cable, the opening and the terminal rod 4 form a groove, the connecting sleeve 2 is fixed on the terminal rod 4, and the connection The upper end of the sleeve 2 is placed in the groove, the lower end of the connecting sleeve 2 is connected with the protective sleeve 1, and one end of the wiring rod 4 is in a hollow structure and placed in the protective sleeve 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com