Monitoring process for grease-lubricated rotating system and corresponding system

A grease-lubricated and greased technology, applied in the field of water content measurement in bearing grease, can solve problems such as damage or destruction, reduce lubrication of rotating systems, achieve low cost and reduce the risk of misconfiguration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The monitoring system includes a processing unit that links to ( / connected to / link) (Linked to) measurement system, which is used to measure the water content within the lubricant of the rotating system (in particular bearing). Processing units typically include a processor and at least one memory for storing data.

[0032] Electrolytic Measurement System includes: electrodes in contact with the lipid, the electrode is connected in series with the current source and the resistor; and the measuring components connected in parallel with the resistor. The output signal of the electrolysis measuring system is linked to the voltage drop in the resistor.

[0033] Instead of attempting to achieve an absolute measure of the water content in the lipid, the system seeks to determine the relative measurement of the water content of the predetermined time period, wherein the water content is considered to be sufficiently low to avoid any damage to the machine.

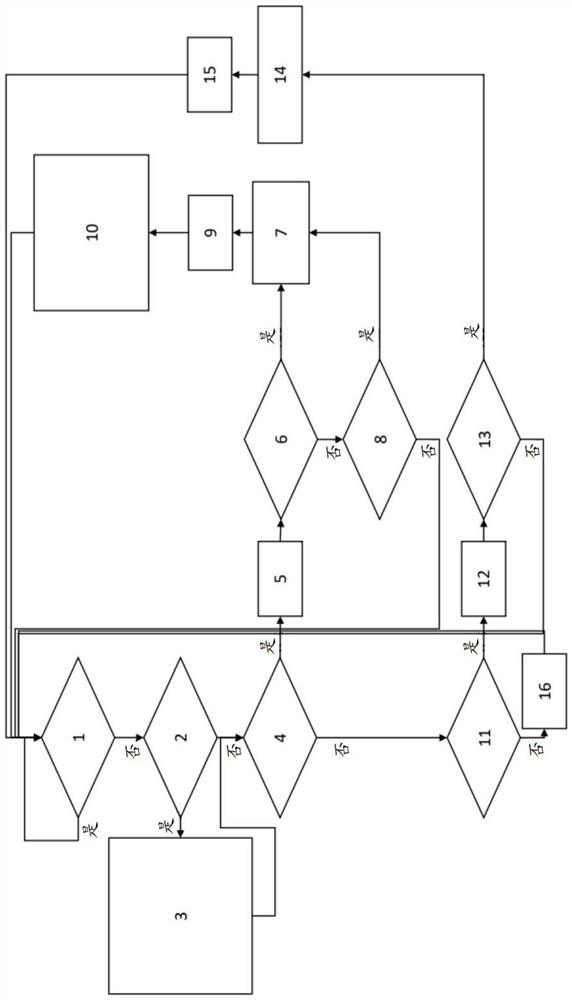

[0034] figure 1 An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com