Machine vision flaw tracking and positioning system

A technology of tracking and positioning and machine vision, which is applied in the direction of optical test defect/defect, program control in sequence/logic controller, electrical program control, etc., to reduce workload, save time and facilitate work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

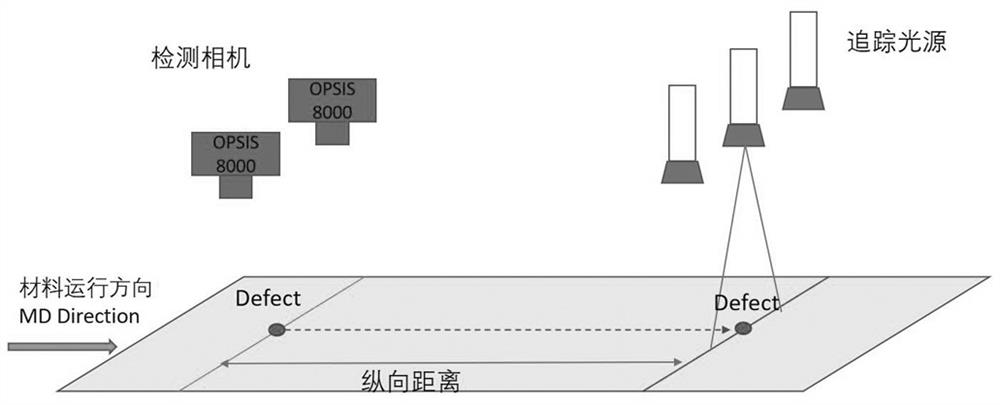

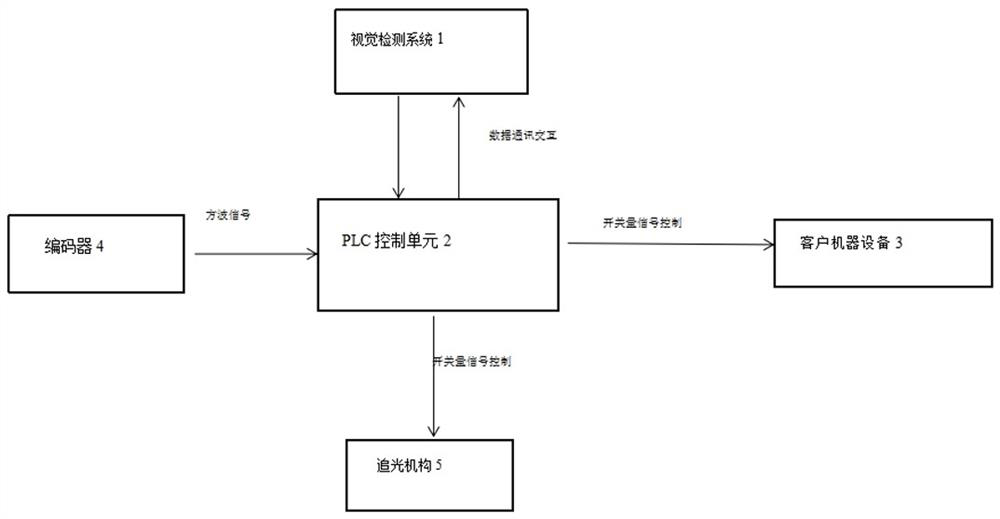

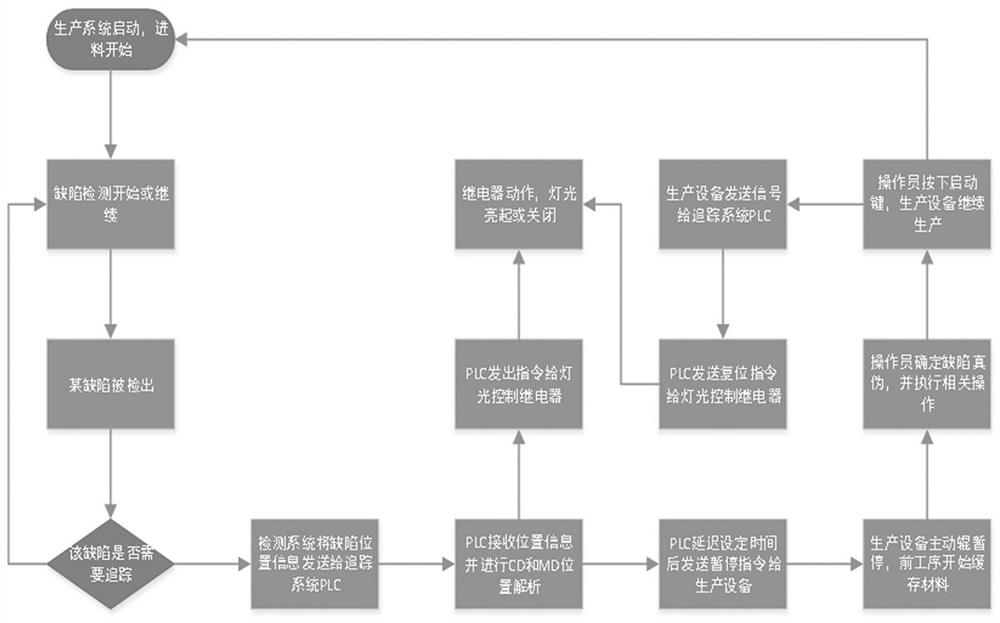

[0018] This embodiment is a machine vision defect tracking and positioning system, which is installed on a production line machine and includes a PLC control unit, a visual inspection device, a light tracking mechanism, an encoder, and the like.

[0019] In this example, the PLC control unit circuit is connected to the control unit of the production line machine, and the production line machine can be controlled to stop by the control unit of the production line machine.

[0020] In this embodiment, the visual detection device has a camera and a data processing unit. The camera is set corresponding to the product on the production line machine, and is used to obtain the product image of the product on the production line machine. The data processing unit analyzes the product image according to the existing defect recognition algorithm. Identify and classify defects on products.

[0021] In this embodiment, according to the requirements of customers, different types of defects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com