Mechanical property prediction method for non-isothermal vulcanization of rubber material

A rubber material and performance prediction technology, which is used in the analysis of materials, testing the strength of materials with stable torsion, and testing the strength of materials with stable tension/pressure. Simple, avoid systematic errors, reduce the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In the present invention, the preparation method of the rubber material preferably includes:

[0060] The components in the rubber material are mixed according to the proportion by weight.

[0061] The present invention has no special limitation on the mixing method, and those skilled in the art can perform mixing with a suitable process according to different rubber materials.

[0062] In the present invention, the rubber material is preferably a cylindrical sample cut according to the test standard (RPA test); the quality of the rubber material is preferably 5.5-6.5g, more preferably 5.8-6.2g, most preferably 6g.

[0063] In the present invention, the reappearance method of the non-isothermal vulcanization process preferably includes:

[0064] During the vulcanization process of the rubber material, the temperature change curve is obtained by means of temperature measurement;

[0065] Select data points on the variable temperature curve to connect to form a recurre...

Embodiment 1

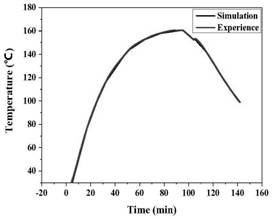

[0096] During the trial production process of an aviation tire (vulcanization stage), the temperature change curve is obtained by measuring the temperature with a thermocouple, and a data point is taken every 5 minutes, and connected into a recurrence curve, such as figure 1 shown.

[0097] Take 6g of the tire carcass rubber compound sample to make the RPA sample, according to figure 1 The recurrence curve shown is vulcanized in RPA; after the vulcanization is completed, the temperature is kept at 70°C for 10 minutes, and the strain is scanned at 70°C and 100cpm in the strain range of 5% to 70% to obtain the torque-strain curve, as shown in figure 2 shown.

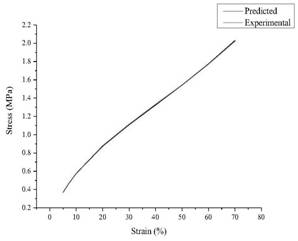

[0098] According to the above formula, the torque is substituted into the calculation to obtain the stress-strain curve, which is compared with the stress-strain curve obtained by the tensile test according to the test standard GB / T 528, such as image 3 shown.

[0099] The results show that the prediction result of th...

Embodiment 2

[0101] In the trial production process of an aviation tire (vulcanization stage), the temperature change curve is obtained by measuring the temperature with a thermocouple; a data point is taken every 5 minutes, and connected into a recurrence curve, such as Figure 4 shown.

[0102] Take 6g of the tire carcass rubber compound sample to make the RPA sample, according to Figure 4 The recurrence curve shown is vulcanized in RPA; after the vulcanization is completed, the temperature is kept at 70°C for 10 minutes, and the strain is scanned at 70°C and 100cpm in the strain range of 5% to 70% to obtain the torque-strain curve, as shown in Figure 5 shown.

[0103] According to the above formula, the torque is substituted into the calculation to obtain the stress-strain curve, which is compared with the stress-strain curve obtained by the tensile test according to the test standard GB / T 528, as shown in Figure 6 shown.

[0104] The result shows that the prediction result of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com