Cleaning robot for high-energy pulse shock tunnel

A technology for cleaning robots and shock tunnels, which is used in cleaning methods using tools, testing of machine/structural components, instruments, etc., can solve the problem of high-energy pulsed shock tunnels, which are difficult to clean, long in laying length, time-consuming and labor-intensive. and other problems, to achieve the effect of quickly and efficiently recycling robots, saving time, and avoiding continuous damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

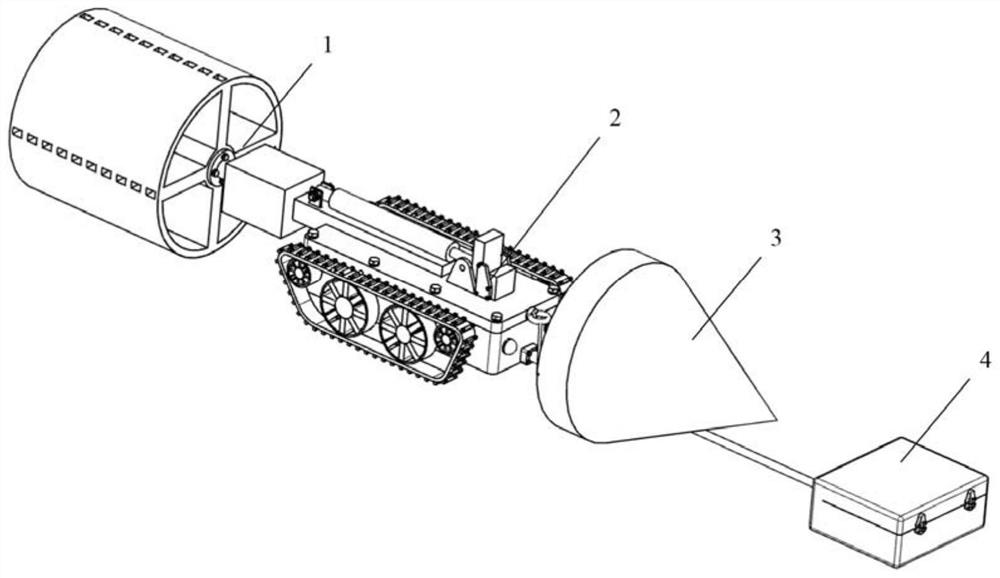

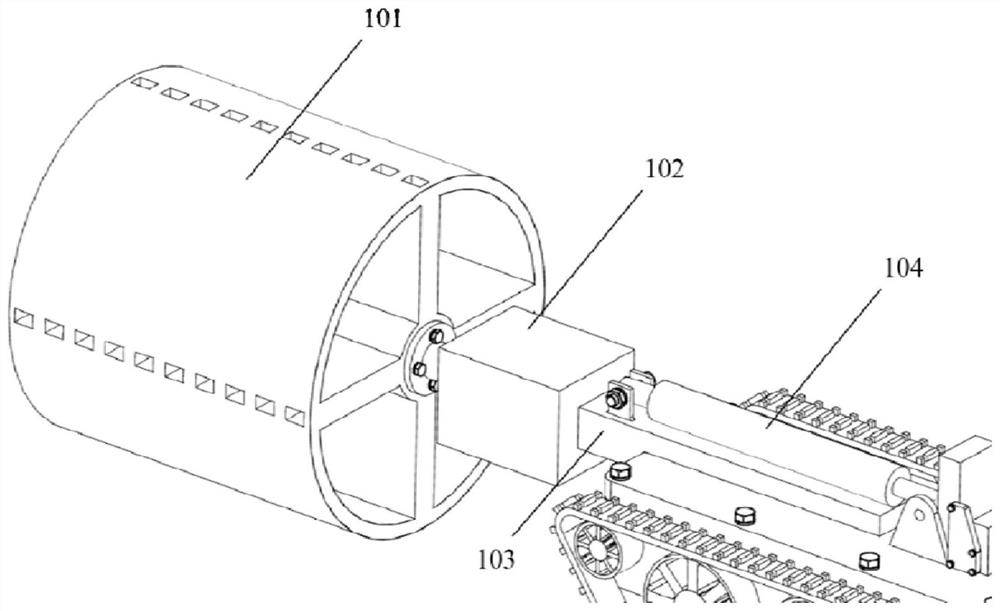

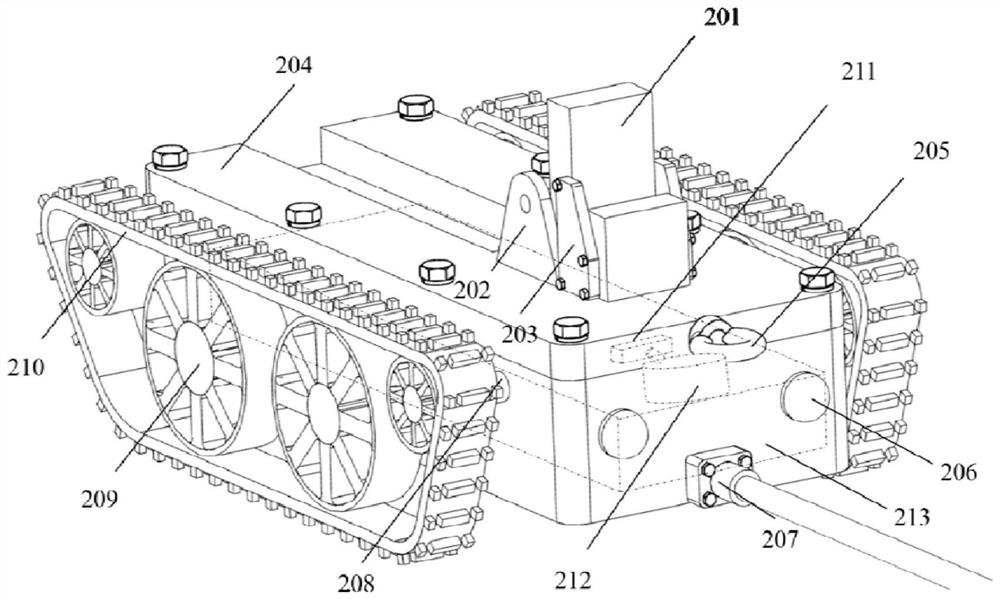

[0038] combine Figure 1 to Figure 5As shown, the cleaning robot for the high-energy pulsed shock wave wind tunnel of the present embodiment includes a brush roller system 1, a walking system 2, a sewage collection system 3 and a control system 4 connected in sequence, and the brush roller system 1 includes a brush roller 101 and is used for driving The brush roller motor 102 that the brush roller 101 rotates is distributed with spray holes for spraying the cleaning medium on the outer wall of the brush roller 101, and the walking system 2 includes a walking device for walking and a medium conveying device for delivering the cleaning medium to the spray holes. The medium conveying device communicates with the spray hole through the medium conveying pipe. The sewage collection system 3 includes a spring hose 302 matched with the wind tunnel pipe and a dust bag 303 arranged downstream of the spring hose 302. The control system 4 communicates with the brush through a cable 401. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com