Solid catalyst component and catalyst system for producing polymers

A solid catalyst and compound technology, applied in the field of olefin polymerization, can solve the problems of high polymerization activity, low polymerization activity and stereoregularity, and insufficient hydrogen modulation sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0085] According to a preferred embodiment of the present invention, the external electron donor compound includes a compound represented by general formula (III):

[0086] R 2 k Si(OR 3 ) 4-k (III)

[0087] In general formula (III), 0≤k≤3; R 2 is an alkyl group, a cycloalkyl group, an aryl group, a haloalkyl group, an amino group, a halogen or a hydrogen atom; R 3 is alkyl, cycloalkyl, aryl, haloalkyl or amino.

[0088] According to some embodiments of the present invention, R 2 for C 1 -C 10 Alkyl, C 3 -C 10 Cycloalkyl, C 6 -C 20 Aryl, C 1 -C 10 Haloalkyl, amino, halogen or hydrogen atom.

[0089] According to some embodiments of the present invention, R 3 for C 1 -C 10 Alkyl, C 3 -C 10 Cycloalkyl, C 6 -C 20 Aryl, C 1 -C 10 Haloalkyl or amino groups.

[0090] In the catalyst system of the present invention, the alkylaluminum compound has the general formula AlR 4 n x 3-n compounds, where R 4 is hydrogen or a hydrocarbon group with 1-20 carbon at...

Embodiment 1

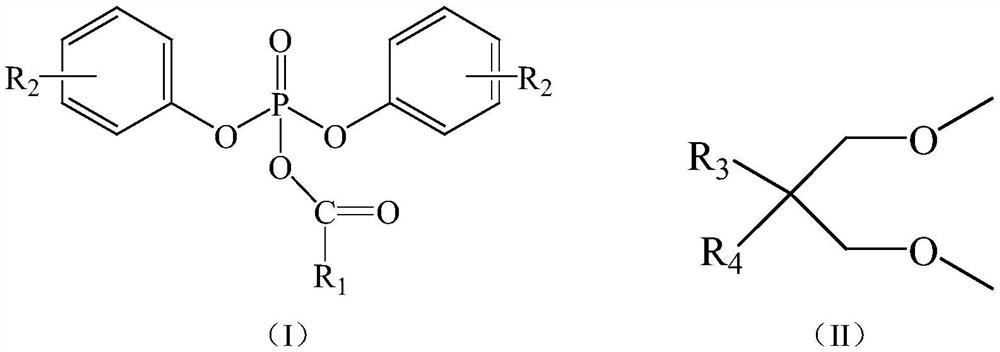

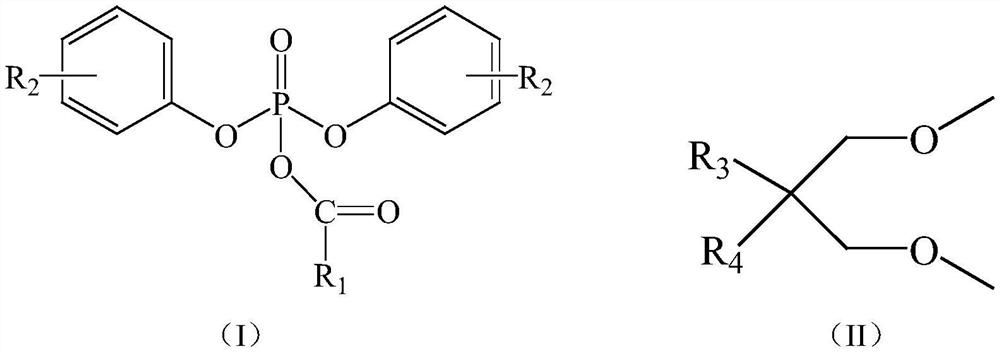

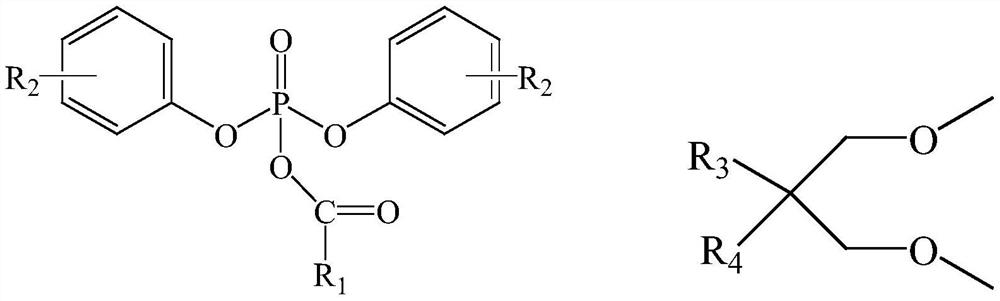

[0110] Preparation of the solid catalyst component: In a reactor fully replaced by high-purity nitrogen, add 4.8g of magnesium chloride, 95mL of toluene, 4mL of epichlorohydrin, and 12.5mL of tributyl phosphate in sequence, and raise the temperature to 50°C while stirring, and maintain After 2.5h, the solid was completely dissolved, and 1.4g of phthalic anhydride was added and maintained for 1h. Cool the solution to below -25°C, add 56mL of TiCl dropwise within 1h 4 , slowly warming up to 80°C, solids gradually precipitated during the heating process, adding 4.2mmol cinnamoyloxy diphenyl phosphate and 0.8mmol 9,9-bis(methoxymethyl)fluorene compound internal electron donor The compound was maintained at the temperature for 1 h, and after filtration, it was washed twice with 70 mL of toluene to obtain a solid precipitate. Then add 60mL toluene, 40mL TiCl 4 , the temperature was raised to 110°C, maintained for 2h, the same operation was repeated once, and then washed three time...

Embodiment 2

[0113] The method is the same as in Example 1, except that the internal electron donor compound is a mixture of 0.5mmol acetoxy diphenyl phosphate and 4.5mmol 2-isopropyl-2-isoamyl-1,3-dimethoxypropane Compound internal electron donor compounds. The activity of the catalyst is 67.3kgPP / (g.cat), the isotactic index is 98.5%, the melt index is 13.0g / 10min, and the molecular weight distribution is 7.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com