Efficient glass fiber reinforced plastic septic tank structure for domestic sewage treatment

A technology for domestic sewage and glass tempering, applied in biological water/sewage treatment, biological sludge treatment, water/sludge/sewage treatment, etc. Effective deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

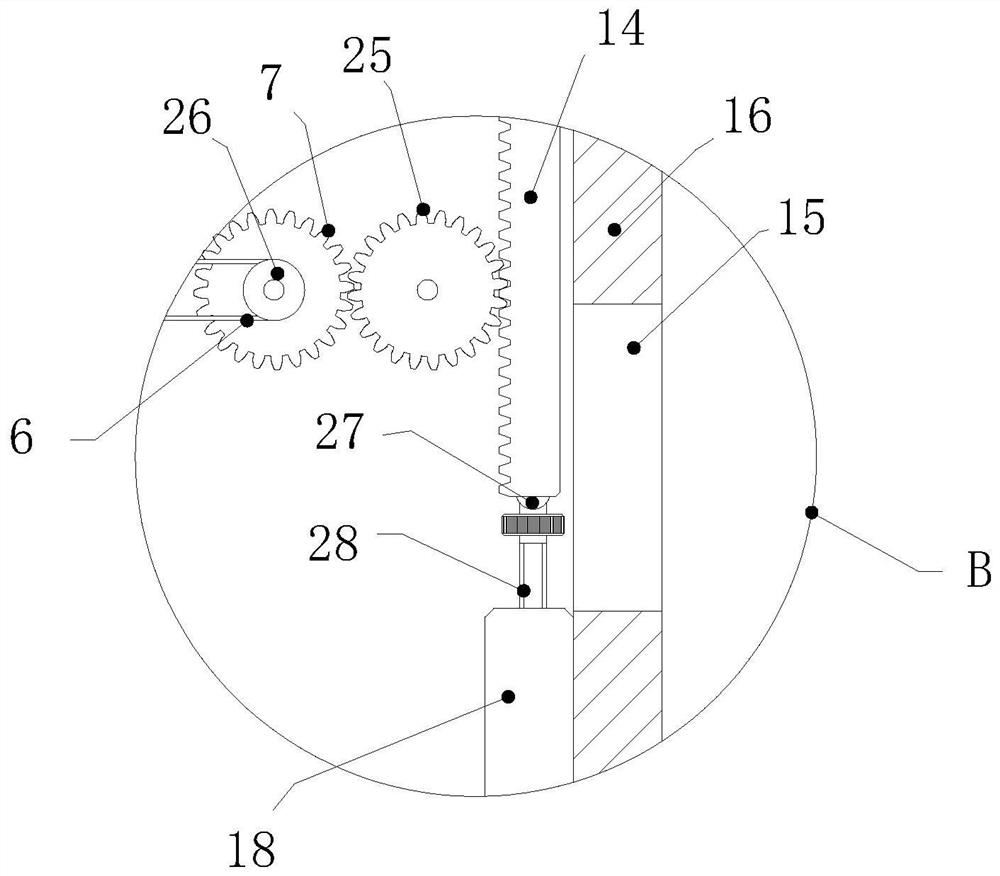

[0023] Such as Figure 1-3 As shown, a high-efficiency domestic sewage treatment fiberglass septic tank structure includes a body of the septic tank, a first partition 16, a second partition 10 are arranged in the body, the first partition 16, the second partition 10 Divide the interior of the main body into a primary corrosion tank 22, a deep corrosion tank 9, and a clarification tank 11 in sequence. The main body is provided with a water inlet 1, a water outlet 12, and a first partition that communicate with the primary corrosion tank 22 and the clarification tank 11. 16. The second partition 10 is provided with a first overflow port 15 and a second overflow port 13 respectively, and a column 3 is vertically provided in the primary corrosion tank 22, and a floating plate 21 that can slide up and down freely is set on the column 3 , the floating plate 21 follows the rise and fall of the liquid level in the primary corrosion tank 22, and there is a buffer bin 2 with an open to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com