Device for disassembling and assembling slotted countersunk head nut of aircraft canopy

An aircraft cockpit and nut technology, which is applied to screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of no discovery, special nut shape, and canopy repair work cannot be carried out normally, so as to ensure the quality of repair and the effect of simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

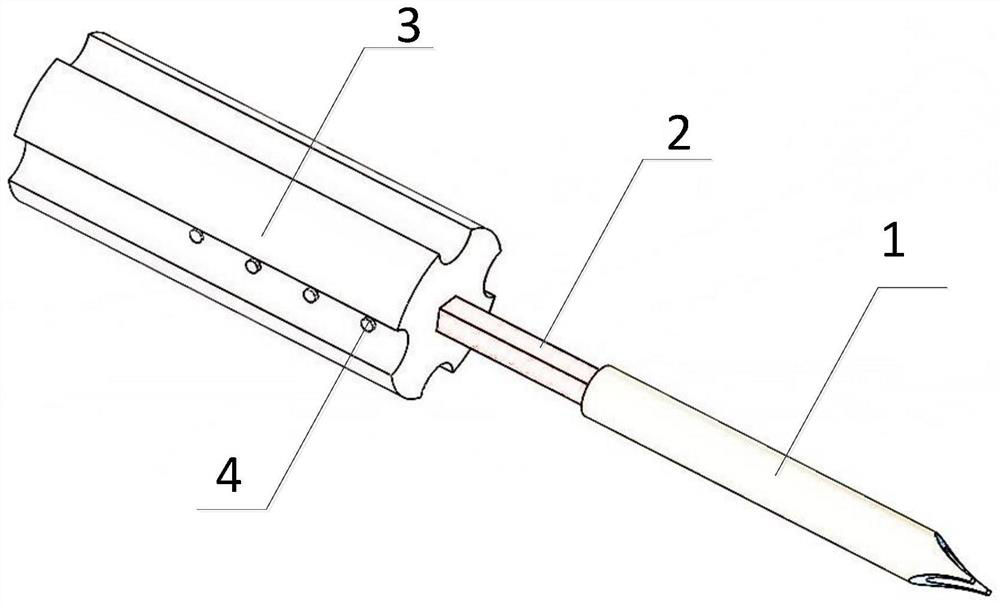

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0028] The present invention provides a kind of purpose of the present invention is realized by the following technical solutions:

[0029] An aircraft slotted countersunk nut Q / 6A1-402 dismounting device, the device includes:

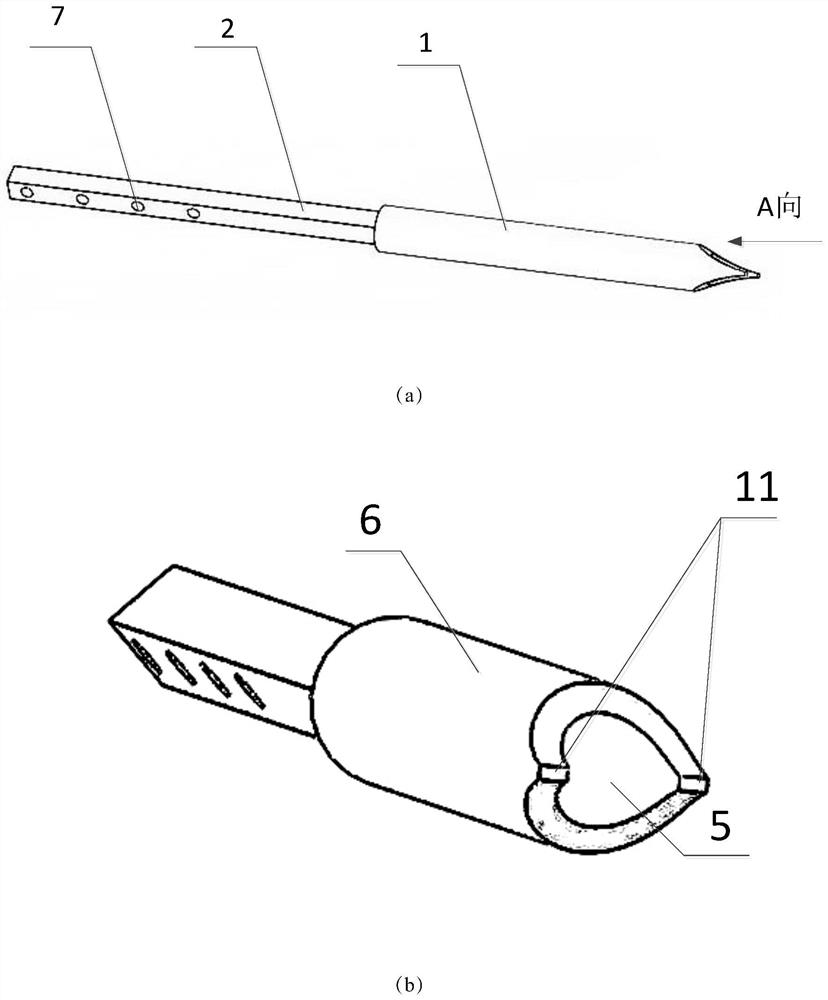

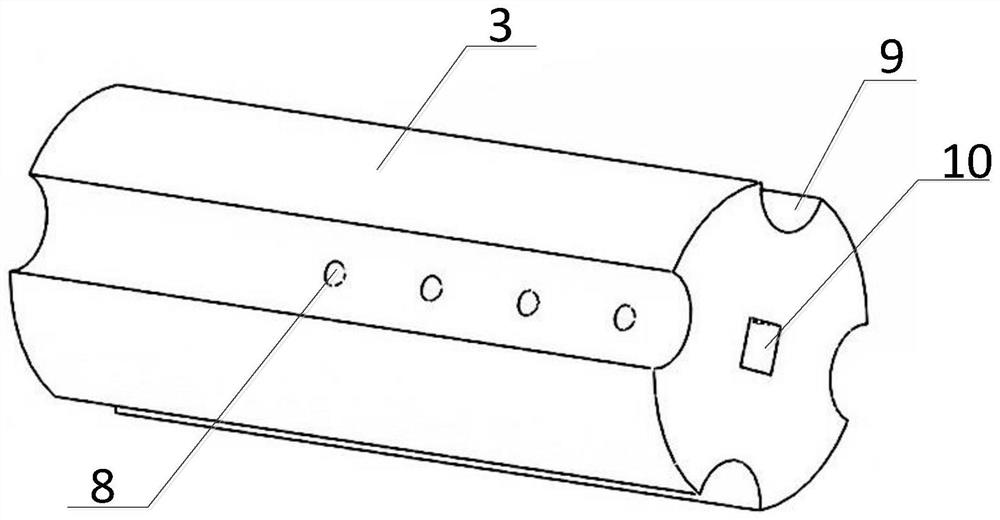

[0030] Two tooth heads 1, booster rod 2, wrench handle 3, rivet 4, round hole 5, U-shaped notch 6, booster rod rivet hole 7, wrench handle rivet hole 8, wrench handle semicircle groove 9, square hole 10, tip Tooth 11;

[0031] Peripheral equipment includes: slotted countersunk nut Q / 6A1-40212, nut notch 13, bolt 14, bolt head 15, open-end wrench 16;

[0032] Wherein, two tooth heads 1 are cylindrical, internally make circular holes 5, make two oblique U-shaped notches 6 at the head, form two canines 11, and the width dimension of canines 11 increases gradually from the root, guarantees strength and service life;

[0033] The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com