Fly ash carbon content soft measurement method and monitoring system based on hierarchical polynomial model

A technology of fly ash carbon content and polynomial model, which is applied to measuring devices, analyzing materials, complex mathematical operations, etc., and can solve problems such as increasing the complexity of combustion parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

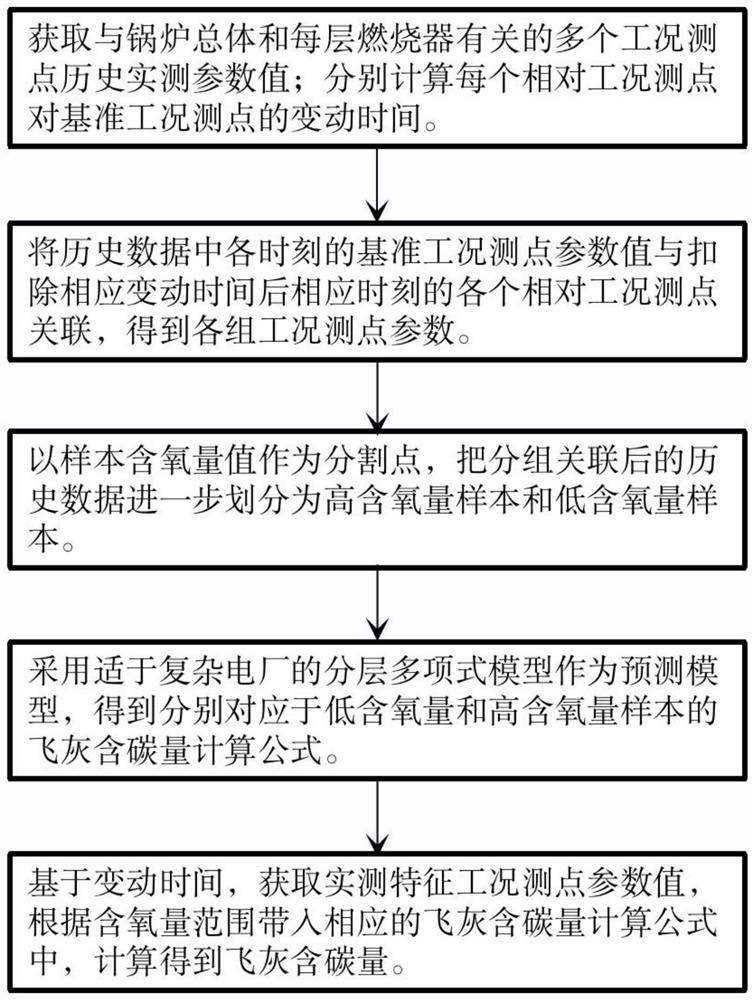

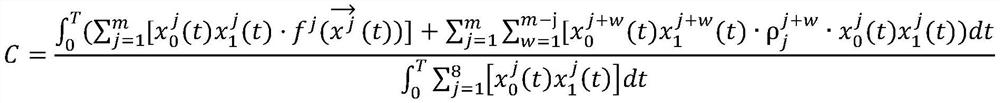

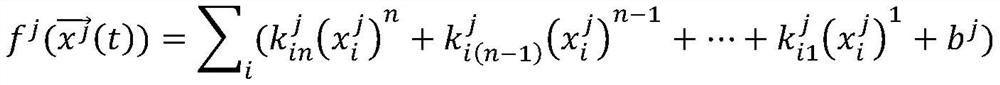

Method used

Image

Examples

Embodiment 1

[0058] In the first embodiment, the final carbon content prediction model of the fly ash is obtained by using the soft measurement method of the carbon content of the fly ash based on the layered polynomial model, and the soft measurement value of the carbon content of the fly ash is calculated by using the model, which specifically includes the following steps:

[0059]Step 1. Obtain historical data of all power plant operating conditions in a period of time (for example, 90 days), wherein the operating condition measurement points obtained include the coal feeding amount of each coal mill, the primary air pressure, air temperature, Air volume, separator outlet temperature and current, etc., the opening of the secondary air door on each floor, the temperature, pressure, air volume and oxygen content of the primary air and secondary air related to the air preheater, the air supply temperature, pressure, Air volume, oxygen content of the tail flue, exhaust gas temperature, and s...

Embodiment 2

[0082] The second embodiment is a system for on-line monitoring of carbon content in fly ash using the soft measurement method of carbon content in fly ash based on the layered polynomial model in embodiment 1. The specific monitoring method of the system is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com