External dry type tube ice maker

An ice machine and dry-type technology, applied in ice making, ice making, ice storage/distribution, etc., can solve the problems of large refrigerant charge and high cost of ice making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

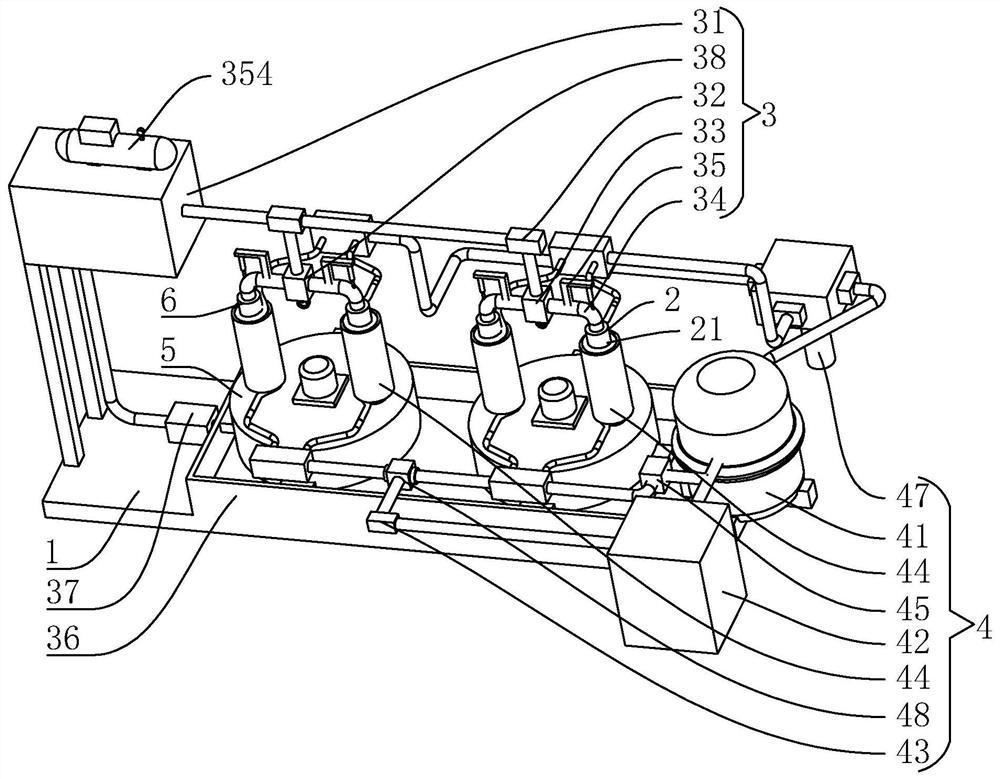

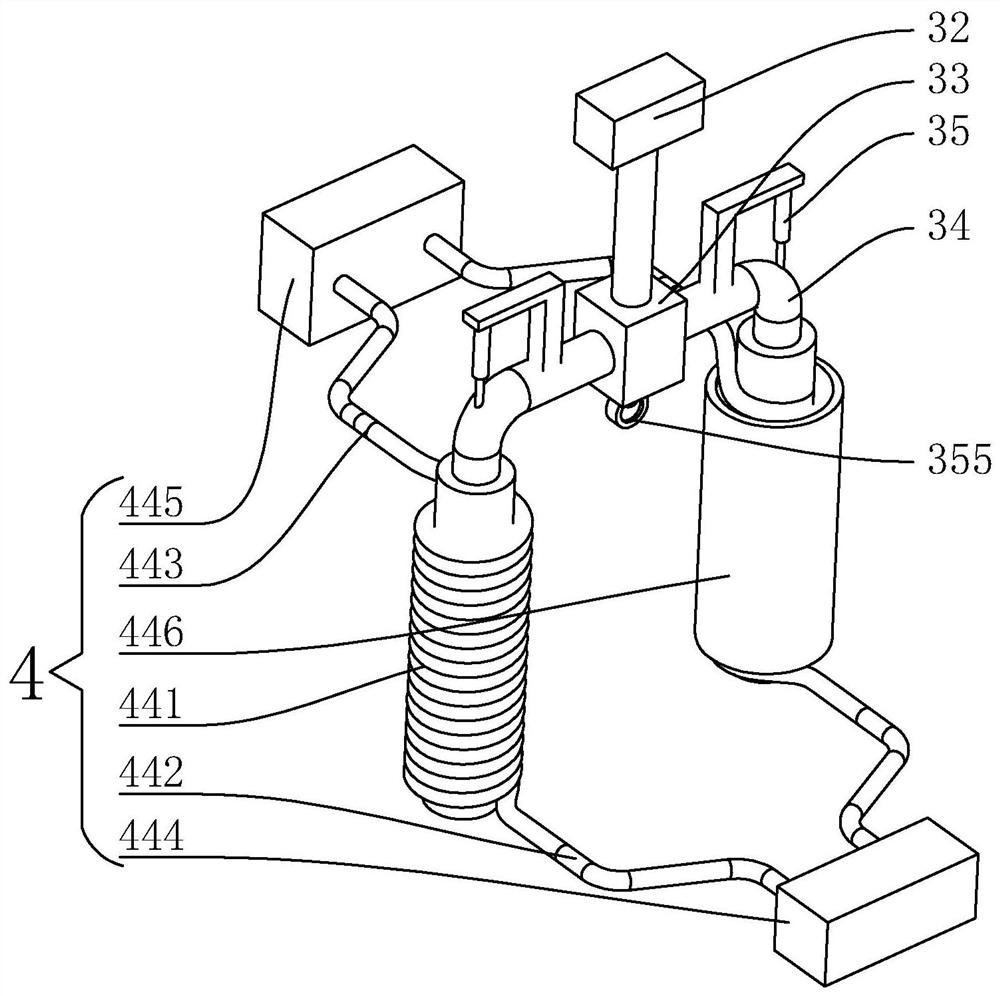

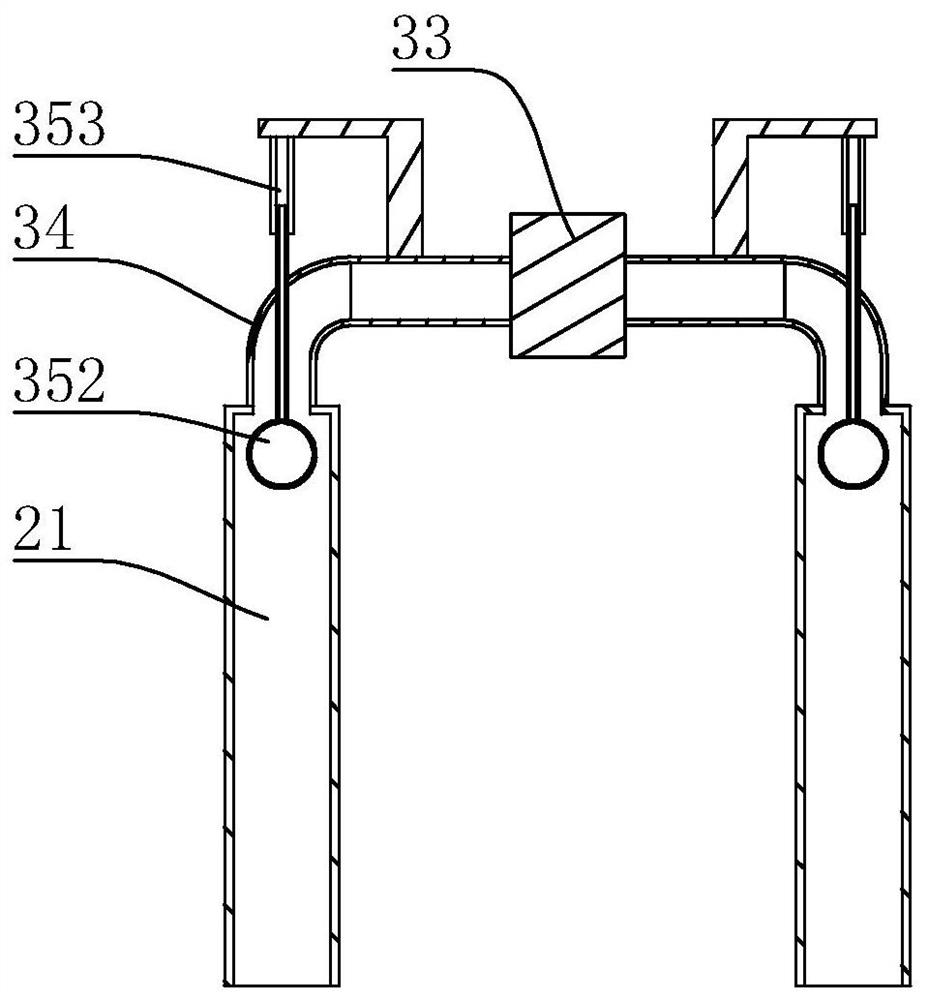

[0031] Preferred Example 1: Reference figure 1 , an external dry tube ice machine, including a frame 1, a first ice-making cylinder 2 composed of several ice-making tubes 21 is arranged on the frame 1, and a The water supply mechanism 3 for raw water and the refrigeration system 4 for cooling by compressing steam and for spirally winding refrigerants in different states around the first ice-making cylinder 2 to produce tubular ice. Ice cutter 5 for cutting ice into several pieces.

[0032] When working, the water supply mechanism 3 first circulates the raw water into the first ice-making cylinder 2, and the refrigeration system 4 first obtains a low-temperature liquid refrigerant through vapor compression and spirally winds it around the first ice-making cylinder 2, and the raw water freezes in the refrigeration tube The tubular ice is formed, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com