Air valve floor automatic configuration method of central range hood system, equipment and medium

A range hood and central technology, which is applied in the field of automatic configuration of the air valve floor of the central range hood system, can solve the problems of parameter writing errors, complex on-site operations, etc., to alleviate parameter writing errors, alleviate complex on-site operations, and configure The process is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] figure 1 It is a flow chart of a method for automatically configuring a damper floor of a central range hood system according to an embodiment of the present invention, and the method is applied to a mobile terminal. Wherein, the mobile terminal is wirelessly connected with the central range hood system; the central range hood system includes: a central range hood host, a cloud platform and at least one power distribution valve.

[0021] Optionally, the mobile terminal carries an air pressure measurement module, which can acquire atmospheric pressure value information or altitude information of the location. In the embodiment of the present invention, the mobile terminal may be a mobile device such as a smart phone or a tablet computer.

[0022] Such as figure 1 As shown, the method provided in the embodiment of the present invention specifically includes the following steps:

[0023] Step S102, establishing a communication connection with the target power distributi...

Embodiment 2

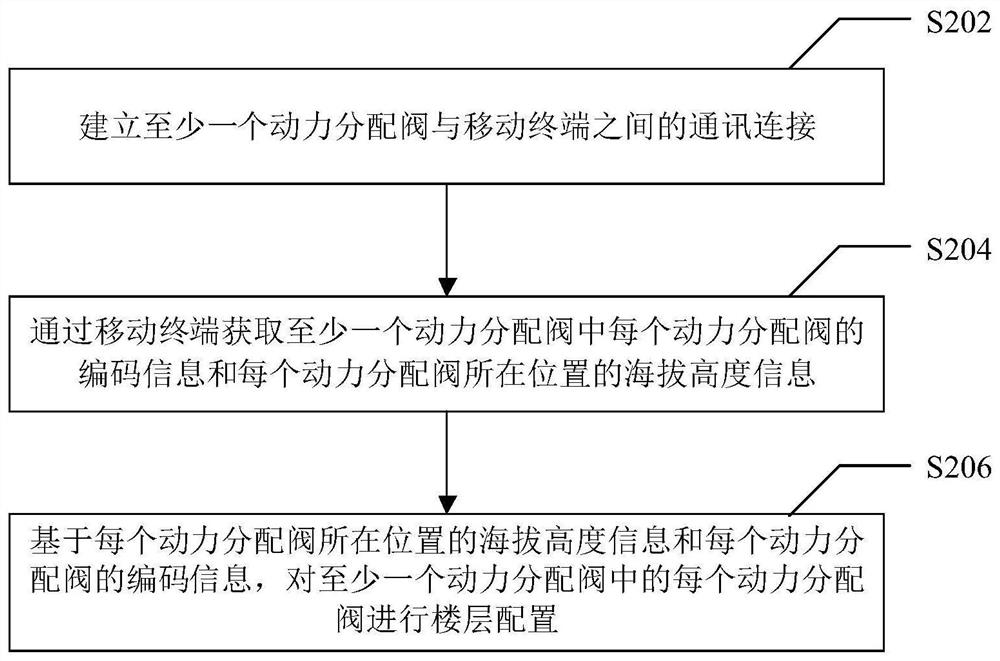

[0029] figure 2 It is a flow chart of another method for automatically configuring a damper floor of a central range hood system according to an embodiment of the present invention, and the method is applied to a central range hood system. Among them, the central range hood system includes: the central range hood host, cloud platform and at least one power distribution valve; each power distribution valve corresponds to a floor; the cloud platform is wirelessly connected to the mobile terminal; the mobile terminal can obtain the altitude of the location A device for information. Optionally, in the embodiment of the present invention, the mobile terminal may be a mobile device such as a smart phone or a tablet computer.

[0030] Such as figure 2 As shown, the method provided in the embodiment of the present invention specifically includes the following steps:

[0031] Step S202, establishing a communication connection between at least one power distribution valve and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com