Air-cooled diesel generator cabinet assembly capable of improving heat dissipation efficiency

A diesel generator, heat dissipation efficiency technology, applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of reducing the continuous running time of the generator set, aging of the engine and generator, cooling the high heat of the generator, etc. Achieve remarkable cooling effect, stable temperature and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

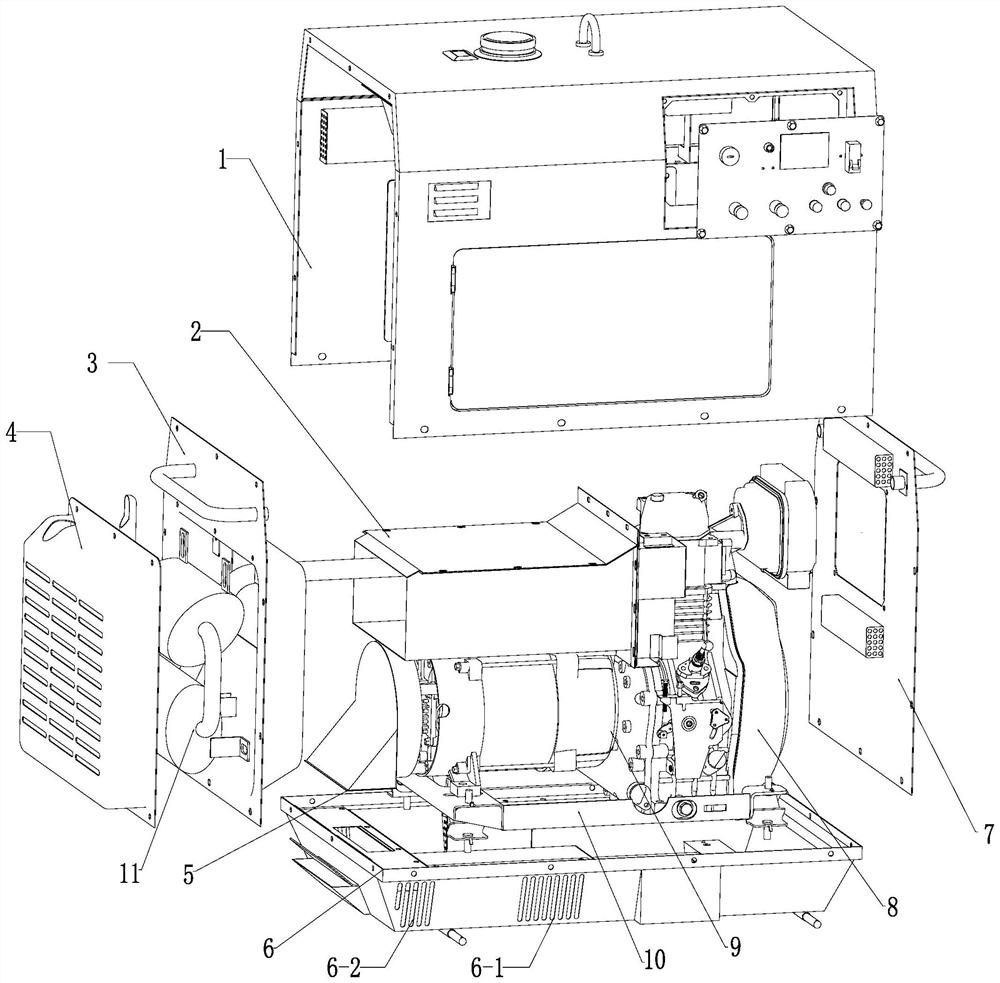

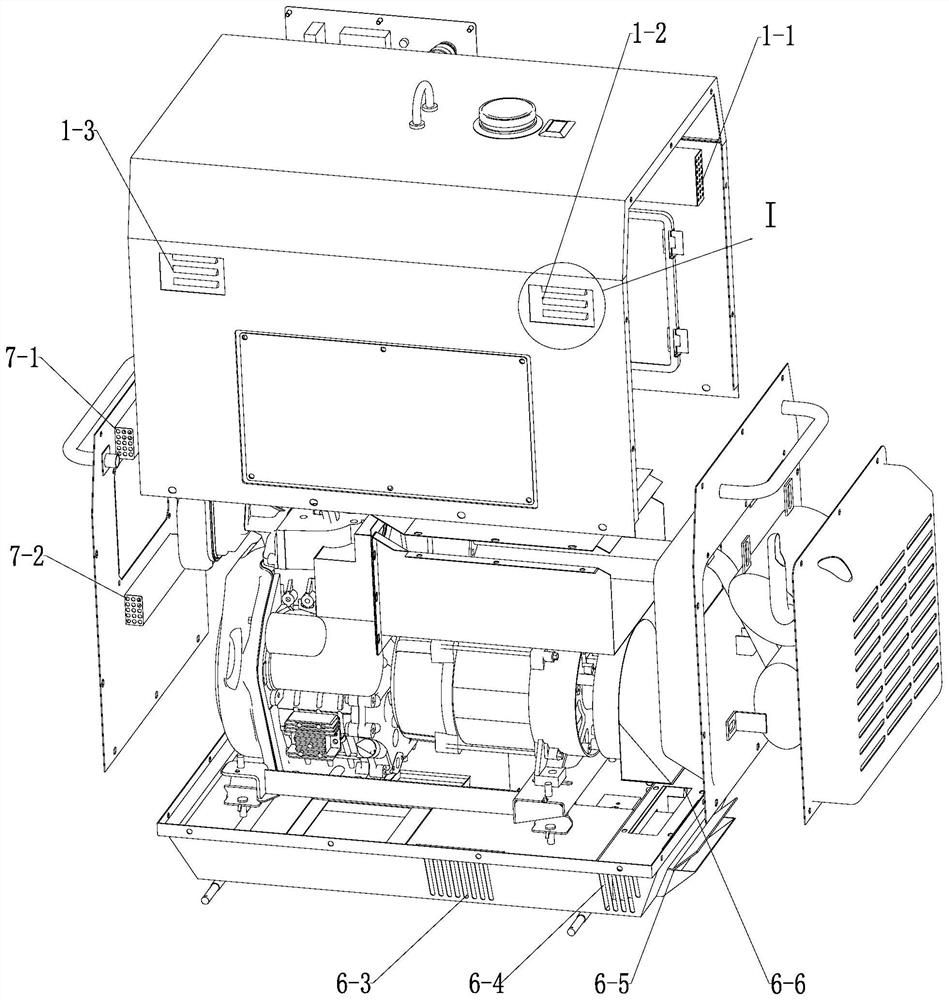

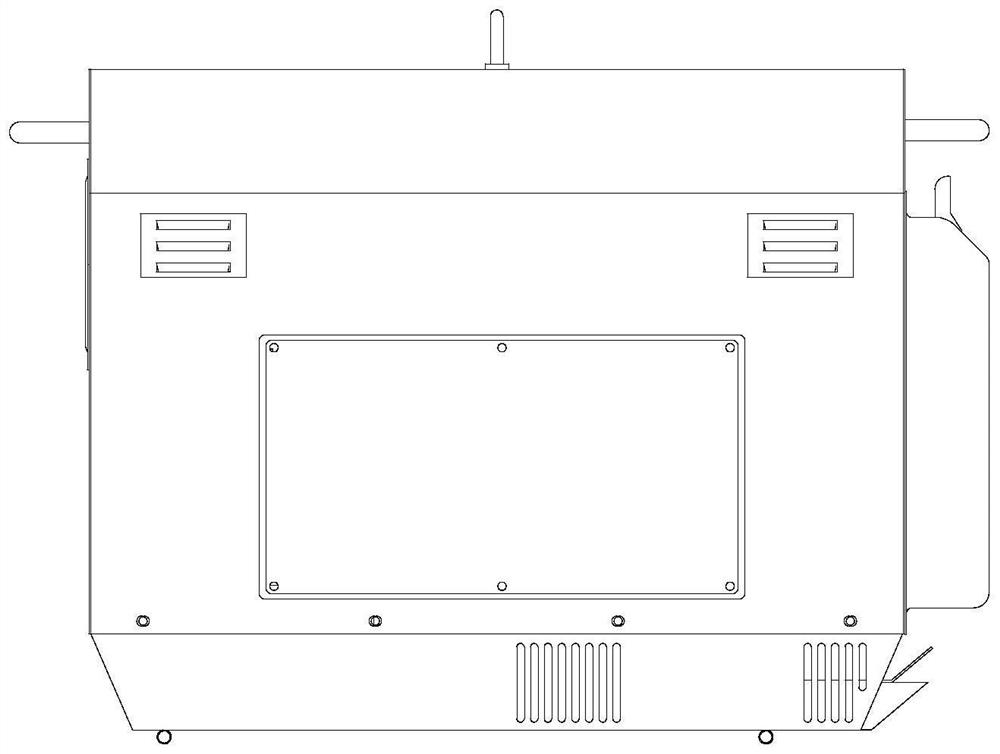

[0022] Such as Figure 1-Figure 2 As shown, an air-cooled diesel generator cabinet assembly that improves heat dissipation efficiency is composed of a cabinet middle frame 1, a heat insulating liner 2, a left side baffle 3, a muffler heat shield 4, a motor intake cover 5, and a cabinet base 6 , Right side baffle plate 7, engine assembly 8, generator assembly 9, bracket 10 and muffler 11 composition.

[0023] The generator assembly 9 is fixed on the engine assembly (8) by bolts, and the fixed engine assembly 8 and generator assembly 9 are fixed on the bracket 10 by bolts, and the bracket 10 is fixed on the cabinet base by bolts 6; the heat insulation liner 2 is fixed on the engine assembly 8 by bolts, wraps the exhaust position of the engine assembly 8, isolates the hot air flowing out of the engine assembly 8, and absorbs the heat sink 8-5 and the cylinder head 8 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com