Long-size cantilever floating plate construction method

A construction method and a long-dimension technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components. To solve problems such as large force, achieve the effect of shortening the construction period, stable and firm support, and reducing load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

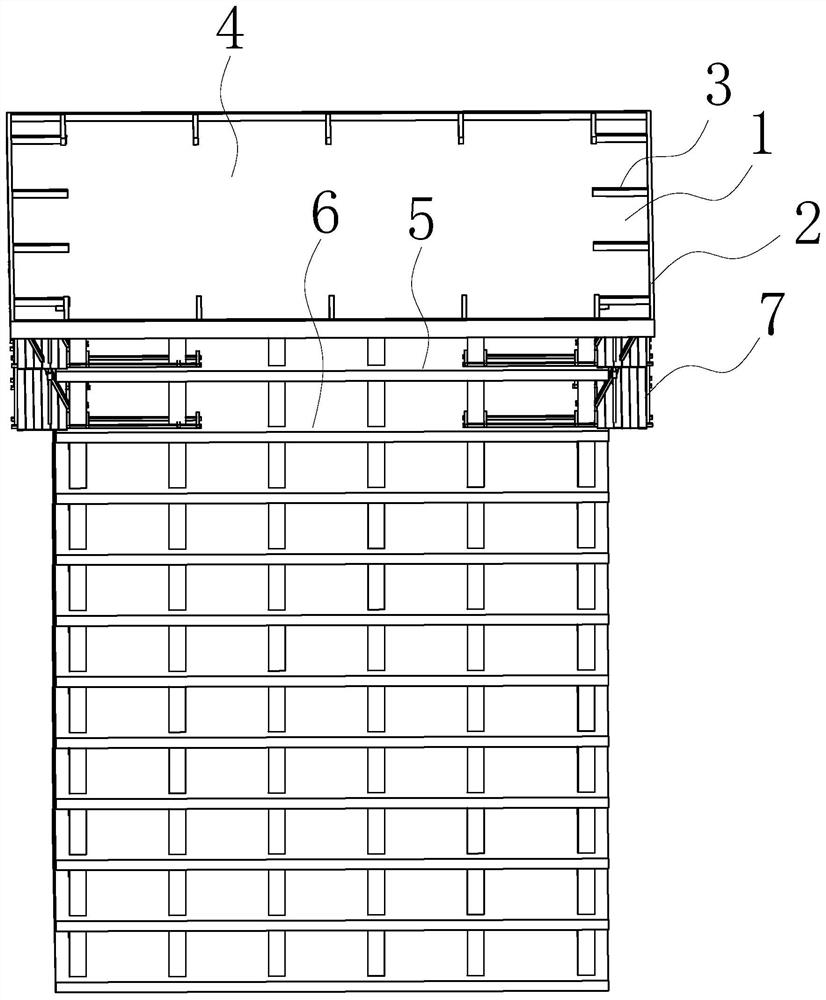

[0034] The following is attached Figure 1-3 The application is described in further detail.

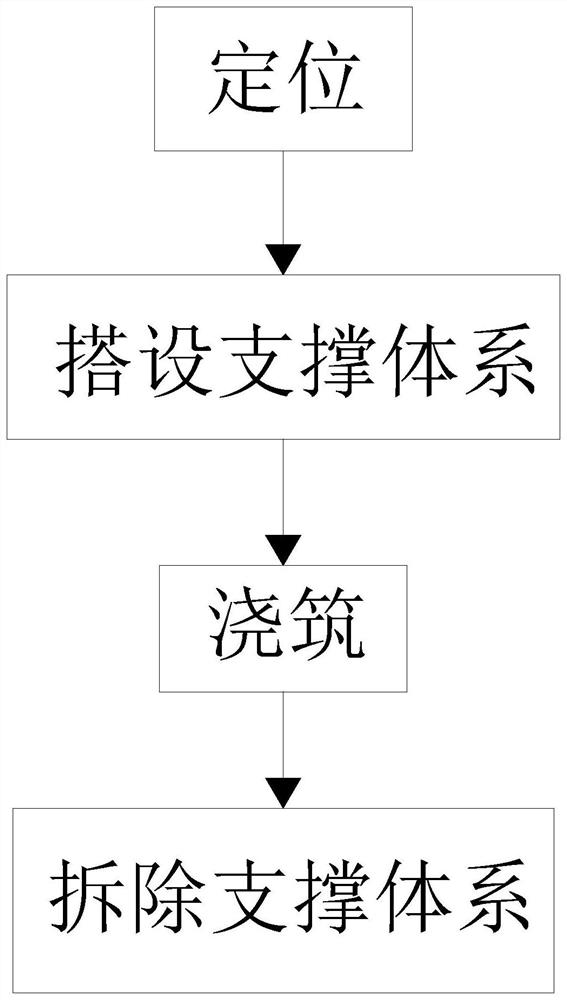

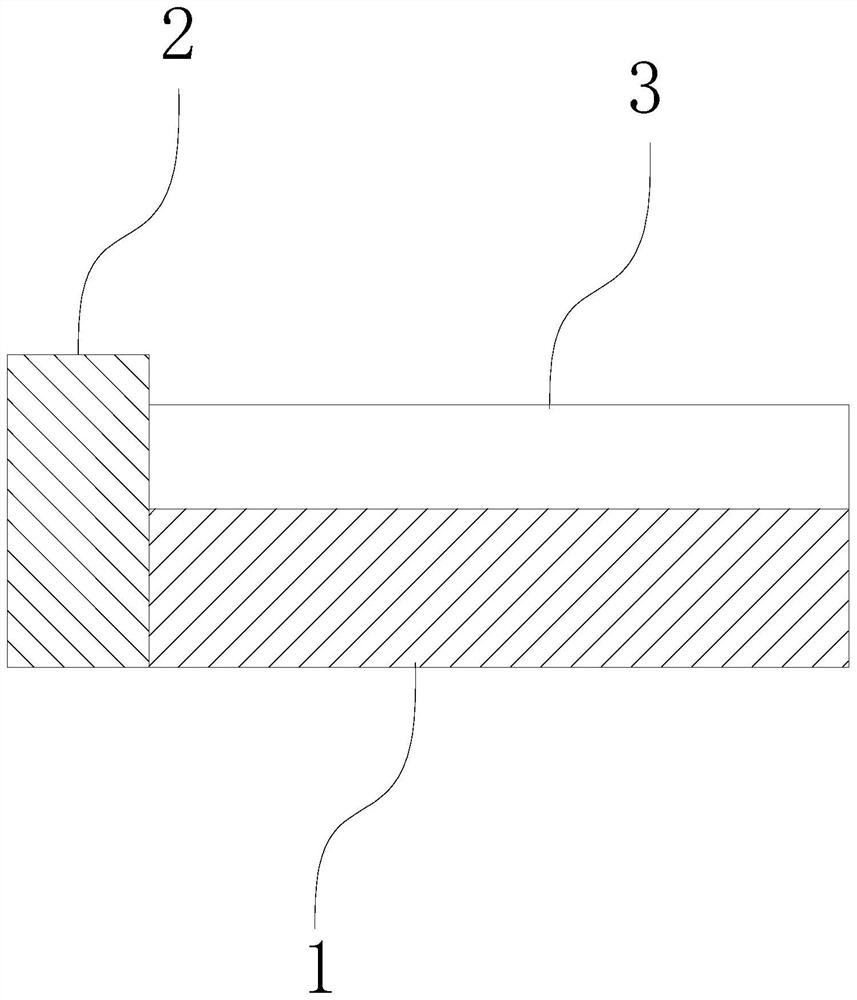

[0035] The embodiment of the present application discloses a construction method for a long-sized cantilevered floating slab. refer to figure 1 , figure 2 and image 3 A construction method for a long-dimension cantilevered floating slab comprises the following steps:

[0036] S1. Positioning: According to the structural construction drawing and architectural construction drawing, determine the size and position of the cantilevered floating slab, and carry out plane setting out and elevation checking, and complete the ground processing of the cantilevered floating slab's reinforcement and formwork.

[0037] S2. Set up the support system: pour the concrete of the top 5 wall columns first, then complete the construction of the non-overhanging formwork support system and the non-overhanging roof 4 formwork, and then set up the formwork support frame 7 of the cantilever floating sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com