Switch rail bottom protective sleeve and preparation method and application thereof

A technology of protective cover and rail bottom, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of the damage of the rail bottom of the tip rail, the overall protection of the rail bottom of the non-tip rail, and the scratch of the rail bottom of the tip rail, so as to protect the tip rail bottom, improve the quality, and the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

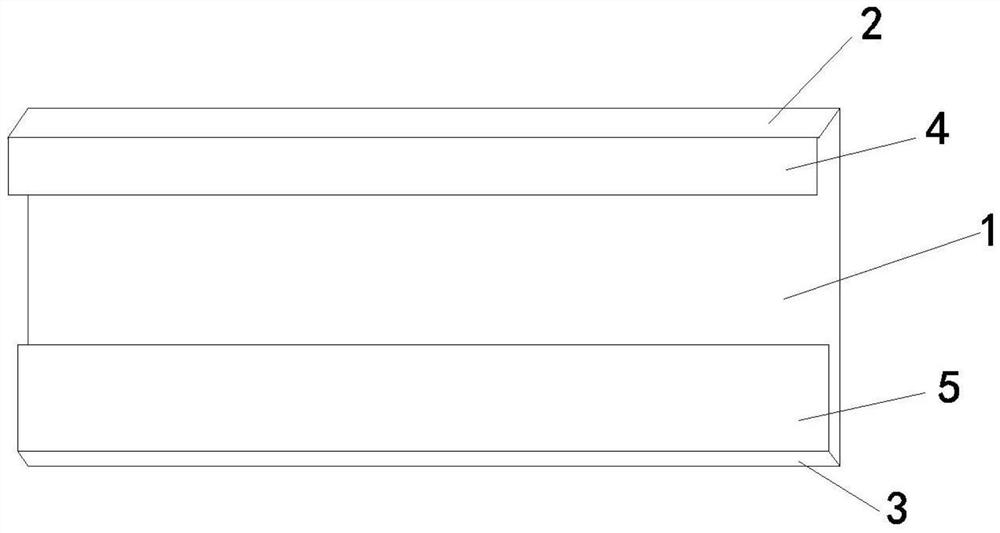

[0044] Such as figure 1 , a switch rail bottom protection cover, including a bottom 1, the two ends of the bottom 1 are respectively vertically provided with a first side wall 2 and a second side wall 3, and the first side wall 2 and the second side wall 3 are at the bottom 1 on the same side; the ends of the first side wall 2 and the second side wall 3 away from the bottom 1 are respectively provided with a first hook structure 4 and a second hook structure 5, and the first hook structure 4 and the second hook structure 5 respectively extend from one end of the first side wall 2 and the second side wall 3 toward the centerline of the bottom 1, and the extended ends are farther away from the side of bottom 1;

[0045] The slope of the first hook structure 4 is 1:2.76; the slope of the second hook structure 5 is 1:17; the width of the first hook structure 4 is 10mm; the second hook The width of the type structure 5 is 70mm; the width of the bottom 1 is 120mm; the height of th...

Embodiment 2

[0048] A switch rail bottom protective cover, comprising a bottom 1, the two ends of the bottom 1 are vertically provided with a first side wall 2 and a second side wall 3 respectively, and the first side wall 2 and the second side wall 3 are arranged on the bottom 1 the same side of the first side wall 2 and the second side wall 3 away from the end of the bottom 1 respectively provided with a first hook structure 4 and a second hook structure 5, the first hook structure 4 and the second hook structure 5 respectively extend from one end of the first side wall 2 and the second side wall 3 toward the center line of the bottom 1, and the extended ends are farther away from the bottom 1 side;

[0049] The slope of the first hook structure 4 is 1:13; the slope of the second hook structure 5 is 1:17; the width of the first hook structure 4 is 10mm; the second hook The width of the type structure 5 is 10mm; the width of the bottom 1 is 130mm; the height of the first side wall 2 is 2...

Embodiment 3

[0052] A switch rail bottom protective cover, comprising a bottom 1, the two ends of the bottom 1 are vertically provided with a first side wall 2 and a second side wall 3 respectively, and the first side wall 2 and the second side wall 3 are arranged on the bottom 1 the same side of the first side wall 2 and the second side wall 3 away from the end of the bottom 1 respectively provided with a first hook structure 4 and a second hook structure 5, the first hook structure 4 and the second hook structure 5 respectively extend from one end of the first side wall 2 and the second side wall 3 toward the center line of the bottom 1, and the extended ends are farther away from the bottom 1 side;

[0053] The slope of the first hook structure 4 is 1:13; the slope of the second hook structure 5 is 1:20; the width of the first hook structure 4 is 50mm; The width of the type structure 5 is 60mm; the width of the bottom 1 is 138mm; the height of the first side wall 2 is 20.9mm; the heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com